FILTERATION OF FUEL OIL

Filters can be classified broadly into two types :

Depth and Surface types.

Depth filters are usually of a felt material or a man made equivalent and are disposable.

Surface filters are usually of metallic mesh.

DEPTH FILTER -

The

oil must pass through an appreciable thickness. The dirt is trapped

because

of the round about path the oil takes.

The holes in the depth filter vary in sizes so any micron rating is nominal and particles larger than the rating may pass through.

The life of these filters depends on the degree of fouling of the oil. However, depth filters with man made fibre elements of the back flushing type are available. This extends the working life considerably before disposal becomes necessary.

SURFACE FILTER -

Made of metallic mesh and designed to have uniform holes. In theory, dirt larger than the holes diameter, does not pass through. But in reality, due to manufacturing imperfection, sometimes bigger size dirts than the micron size holes may pass

through.

SUCTION FILTERS

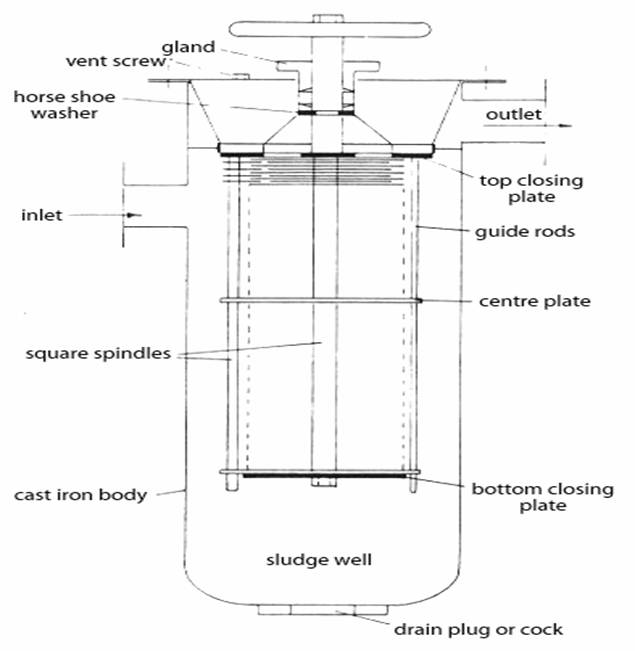

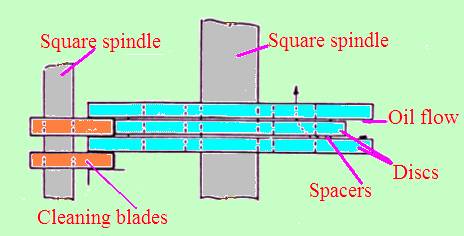

AUTO - KLEAN :

These can be coarse mesh filters as shown. It consists of a stack of thin steel annular discs, mounted on a central spindle. A number of guide rods pass through each disc and the rods cary thin steel washers which separate the discs by a small clearance. Over the bottom disc there is a blank circular plate and the arrangement is mounted so that the oil flow is through the spaces between the discs. Thin steel cleaning blades project into the space between each pair of discs and these are fixed close to stack by means of a square sectioned spindle. The plate stack is rotated past the cleaning blades and these are shaped so that whichever way the stack is rotated, the dirt lodged between the plates is pushed out and falls to the bottom of the chamber. Sometimes magnetic elements are incorporated in "■ filters to trap any loose ferrous particles.

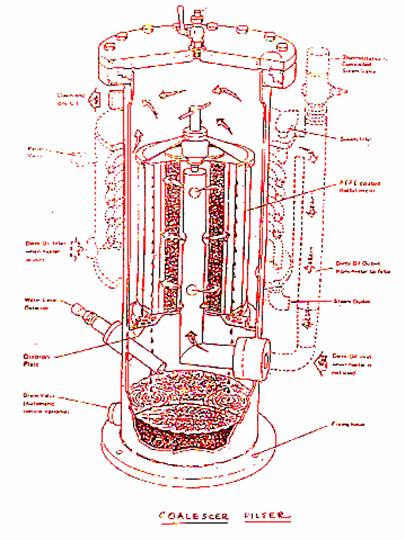

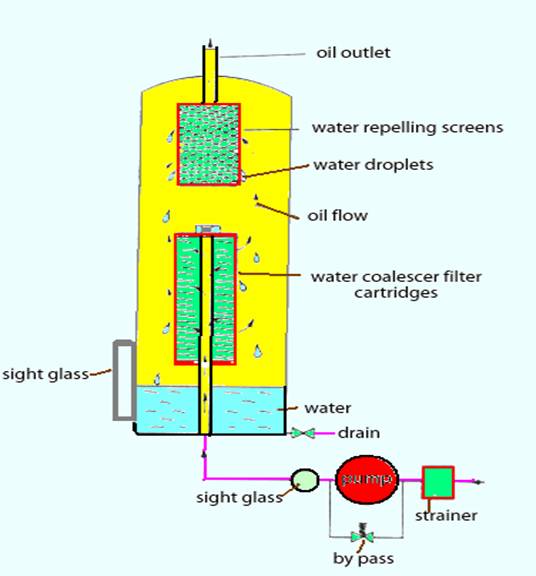

COALESCER FILTER-

A coalescer is a filtering device for use with distillate fuels for the removal of water and solid particles. These filters are designed to handle intermittent water concentrations upto 50%. The particle filtration effectiveness is 98% for 5 micron but this improves during/ service.

Water level after filtration are :

0.001% (10 ppm) Fuel oil 0.01% (100 ppm) lubricating oil.

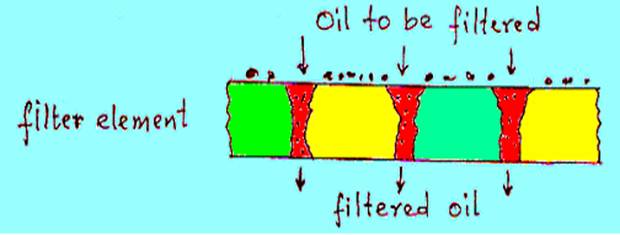

A two-stage operation takes place in the filter coalescer cartridge, which is a single replaceble assembly. The fuel to be treated enters in the central tube and flows radially outward through the cartridge, firstly through a pleated inner element and secondly through the outer coalescer stage. The inner element is made from synthetic fibre is pleated with folds separated by spaers. This inner element removes particulate matters down to 5jll micron from the fuel, so protecting the outer element from excessive quantities of containments. The outer coalescer element, which is made from inorganic fibre suitably pressed to a predetermined density and depth, intercepts water droplets. The molecular attraction between the water droplets and the fibre is greater than that between the oil droplet and fibre. Fine water droplets are agglomerated to such a size that they fall by gravity to the sump at the bottom. To further assist in the removal of water from the fuel, there is a PTFE coated outer steel mesh, which arrests any remaining water droplets. Clean oil comes out from the top and water from the sump be drained either manually or automatically by a float operated valve.