Question

Describe with

detailed Sketch the Arrangement for securing the exhaust gas uptakes in the

funnel casing of a steam or motor ship

Answer.

The size and shape of the

funnel depends upon the requirements of the ship owners. At one time tall

funnels were fitted to steam ships to obtain the required natural draught and,

in passenger ships, to ensure that the smoke and grit were carried clear of the

decks. Modern ships with forced draught do not require such high funnels. The

funnel has now become a feature of the design of the ship, enhancing the

appearance and being a suitable support for the owners house mark. They are

built much larger than necessary, particularly in motor ships where the uptakes

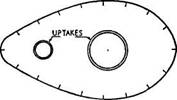

are small. They may be circular, elliptical or pear shaped in plan view, while

there are many varied shapes in side elevation. In many cases the funnel is

designed to house deck stores or auxiliary machinery such as ventilating fan

units.

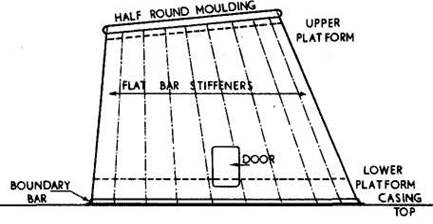

The funnel consists of an

outer casing protecting the uptakes. The outer funnel is constructed of steel

plate 6 mm to 8 mm in thickness. It is stiffened internally by ordinary angles

or flat bars fitted vertically. Their scantlings depend upon the size and shape

of the funnel. The plating is connected to the deck by a boundary angle, while

a moulding is fitted round the

top

to stiffen the free edge. Steel wire stays are connected to lugs on the outside

of the funnel and to similar lugs on the deck. A rigging screw is fitted to

each stay to enable the stays to be tightened. A watertight door is fitted in

the funnel, having clips which may be operated from both sides

(Fig. a).

Fig. a

FUNNEL CONSTRUCTION

PLAN VIEW

ARRANGEMENT OF FUNNEL UPTAKES

Fig. b

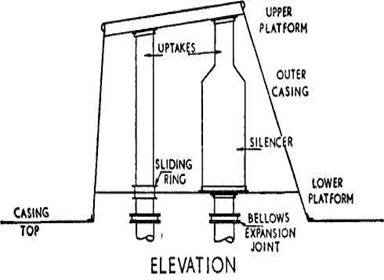

The uptakes from the

boilers, generators and main engine are carried up inside the funnel and

stopped almost level with the top of the funnel (Fig. b). A steel platform is

fitted at a height of about 1 m inside the funnel. This platform extends right

across the funnel, holes being cut in for the uptakes and access. The uptakes

are not connected directly to this platform because of possible expansion, but

a ring is fitted above and below the plating, with a gap which allows the pipe

to slide. Additional bellows expansion joints are arranged where necessary. At

the top a single platform or separate platforms may be fitted to support the

uptakes, the latter being connected by means of an angle ring to the platform.

In motor ships a silencer must be fitted in the funnel to the main engine

exhaust. This unit is supported on a separate seat. Ladders and gratings are

fitted inside the funnel to allow access for inspection and maintenance.