Question

A rudder of a vessel requires extensive

welding repairs and as second engineer you are requested to supervise:

Suggest a suitable type of welding process

State with reasons four common welding

defects

State

what tests may be carried out before returning the rudder to service.

Answer.

a) The welding process most suitable for rudder repair

is Manual Metal Arc welding (MMA). The reasons for using this basic process are

1) It will probably be an in situ repair in Dry dock requiring multj positional welding (down hand, overhead, horizontal, vertical ) . MMA is

versatile in this respect. 2) There will be no special steel involved, thus

basic electrodes , techniques are to be tested. (although castings may be in rudder structure taken care by

preheating). 3) Welding in an exposed environment means that semi automatic

processes such as-MIG would be difficult (shielding gas blown away) unless

protected by an enclosure.

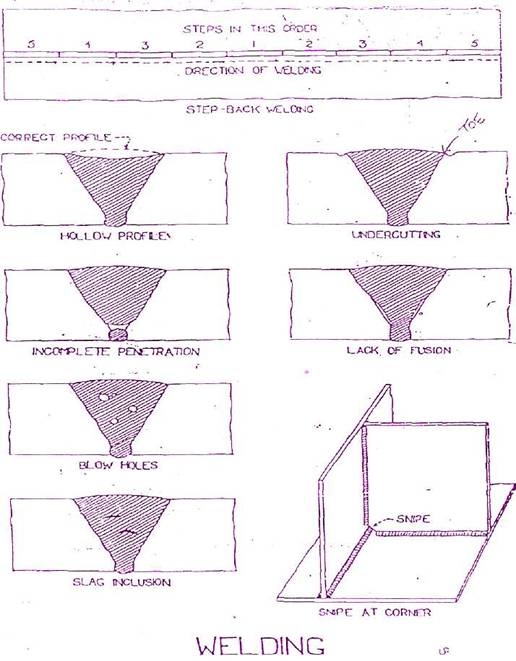

FOUR COMMON WELDING DEFECTS:

1)UNDERCUT: This is a groove or channel along the toe of

the weld caused by wastage of the parent metal which could be due to too high a

welding current or low welding speed.

2)INCLUSION: Any slag or other entrapped matter is an

inclusion defect. Surfaces to be welded must be free from foreign matter e.g. grease , oil, mill scale, metal chipping etc. During welding

the slag must not be allowed to get in front of the molten metal or it may

become entrapped. Also when welding is interrupted for changing of electrodes

or when another run is to be laid , the already

deposited metal should be allowed to cool, the slag should then be chipped and

brushed oft

3) INCOMPLETE ROOT PENETRATION: It is a gap caused by failure of the weld

metal to fill the root This may be due to fast welding speed or too low a current.

4)LACK OF FUSION: This could occur between

weld metal and the parent metal, between different layers of weld metal or

between contact surfaces of parent metal.

It could be caused by incorrect current or voltage, dirt or grease

c ) Rudder should be hydraulically pressure tested up

to 2.4 m of water head for confirming water tight integrity welding work first

should be tested by NDT testing means ,

X-rays , Ultrasonic testing. If it is satisfactory

then hydraulic test should be carried out. Rudder drop to be checked to confirm

no load on the pintle bearings, condition of pintle bearings , free movement of

rudder 35o on either side , external rudder stoppers etc, before rudder is put

back into service. Proper fitment of sacrificial anodes.

Rudder closing plate and bottom drain to be checked for proper fitment. Rudder stock palm nuts to

be covered with cementing.