Question

a) With reference to the importance of good

design and a high standard of workmanship in the fitting and repair of bilge

keels.

(i) Describe how

the design and method of attachment reduces the possibility

of damage to the

shell plate:

(ii) State the authority the must be afforded

the opportunity to inspect the fitting and repair:

(iii) State what non-destructive testing is

carried out

(b) Explain why

bilge keels do not extend for the full length of the ship:

Answer.

(a)

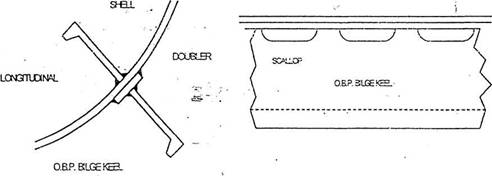

(i) The bilge keels are

attached directly in line with internal stiffening such as a girder or

longitudinal. On thicker shell plating (such as merchant ships) the bilge keel

is made up of a flat bar doubler welded directly to

the shell and an offset bulb plate (OBP) with 'scallops' cut in it is welded to

the flat bar doubler. The ends of the bilge keels are

tapered and if the keels are positioned so that they follow the streamlines at

the service speed of the ship, then the added resistance is only about 2%.

(ii) The Authority that must be afforded the opportunity

to inspect the fitting and repair is the Load Line Assigning Authority Surveyor

(e.g. the Lloyds Register Surveyor)

(iii) The non-destructive testing that must be carried

out is either X-ray or ultrasonic.

(b) Bilge keels are not fitted for the full length of

the vessel because:

(i) The lever to the ships

axis of rotation is reduced at the ends;

(ii) It would be more difficult to make and fit due to

the bending and twisting

required:

(iii) It would be difficult lo align with flow along

the hull, particularly at the fore end.

The hydrodynamic effect would cause a large increase

in resistance and fuel

consumption:

(iv) At the aft end the boundary

layer is much thicker and since the keel would not project through, it would

have much reduced effect