Question

(a) Surface preparation and

painting of new ship plates

(b) Design of the ships

structure and its maintenance

(c )

Cathodic protection by sacrificial anodes, of the internal

and external areas of the ship.

Answer:

(a) If the plates are

immersed in a weak solution of sulphuric acid or hyfrochloric acid

for a few hours the majority of scale is removed. This is pickling. The pickled plate must be hosed

down with fresh water on removal from the tank, allowed to dry before painting.

During drying a light coat of rust is formed and must be removed before

painting.

Flame clearing, oxy

acetylene torch having several jets is used to brush the surface, burns the

dirt and grease, loosens the surface rust,

loosens the mill scale. The surface is immediately wire brushed and

the priming coat applied while still

warm.

Mill scale is removed by

shot blasting. This removes dirt, rust and grease as well. This removes 95% to

100% mill scale and results in slightly rough surface which allows

adequate adhesion of the paint. The

plate is spray painted on emerging from the shot blasting machine.

(b) Direct connection

between dissimilar metals should be avoided or effectively insulated from each

other. Avoid trapping quantities of sea water or any electrolyte, crevices by

selection of construction members of suitable radiused

section or by sealing.

Larger

enough drains to be provided to drain water and dirt.

Tanks should be provided with drains to enable complete draining with out

leaving any residue.

The metals should be

protected prior to assembly and prevent water soaking into porous materials. Sharp edges where the paint draws

away should be removed.

If two dissimilar metals are used paint all the

surfaces or at least the more cathodic material. Weld

metal of more noble quality than the parent metal -should be used. Traces of

residual surface products (slag which is cathodic

sometimes) of welding, should be cleaned before painting.

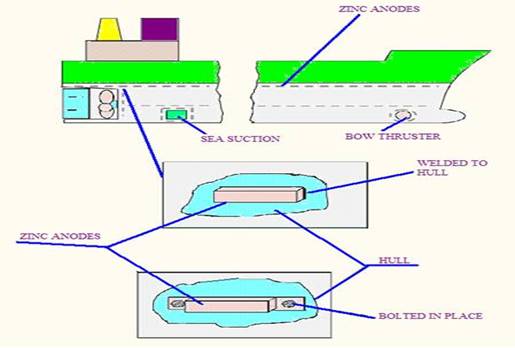

(c) Zinc or aluminium anodes are used as sacrificial anodes for the

protection of external areas of the ship. Zinc is allowed corrode in preference

to steel hull and propeller. And also protects hull due to differences in

steel. The current is provided by sacrificial anodes attached to the ships hull

which form a short circuited cell with the hull as cathode and sea water as

electrolyte. This system does not require any maintenance but a large number of

bulky anodes are required to give full protection until next drydock.

Deep water ballast tanks are

also protected by sacrificial zinc anodes. Rust is to be removed and a film of

the anode material is to be formed. This is achieved by using booster anodes

having large surface area

compared with their volume. To maintain the film main anodes having large

volume compared to surface area are fitted. These are designed to last for

three years. Protection is provide to the whole tank only if the electrolyte is in full contact, it is

necessary to press up the tank when ballasted.