Question.

Describe the DB and framing arrangement used

in the machinery space to cope with concentrated loads and vibration together

with shaft and thrust block support

Give reason for choice of thrust block

position

Answer.

Double bottom in the machinery space

In the machinery space other factors must be taken

into account. Forces of pulsating nature are transmitted through the structure

due to the general out of balance forces of the machinery parts. The machinery

seats must be extremely well supported to prevent any movement of the

machinery. Additional girders are fitted in the double bottom and the thickness

of the tank top increased under the engine in an attempt to reduce the

possibility of movement which could cause severe vibration in the ship. For

similar reasons the shaft and propeller must be well supported.

Great care must be taken in the machinery space to

ensure that the main and auxiliary machinery are efficiently supported. Weak

supports may cause damage to the machinery, while large unsupported panels of

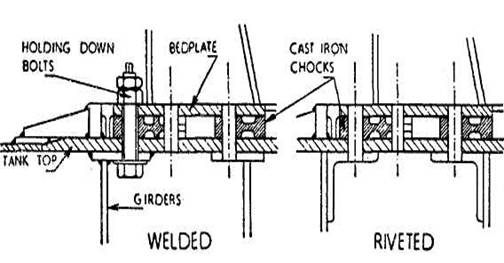

plating may lead to vibration of the structure. The main engine bedplate is

bolted through a tank top plate which is about 40 mm thick and is continuous to

the thrust block seating. A girder is fitted on each side of the bedplate in

such a way that the holding down bolts pass through the top angle of the

girder. In welded ships a horizontal flat is sometimes fitted to the top of the

girder in way of the holding-down bolts.

In motor ships where a drain tank is required under the

machinery, a cofferdam is fitted giving access to the holding down bolts and

isolating the drain from the remainder of the double bottom tanks. Additional

longitudinal girders are fitted in way of heavy auxiliary machinery such as

generators.

Thrust Block Position & Support:-

Main thrust block is placed closed to the propulsion

machinery in order to reduce any problem due to differential expansion of the

shaft and the hull. The low hull temperature of midship

engined refrigerated cargo ships can cause a

contraction of upto 20mm relative to the shaft

whereas water temp, change or heating of fuel tanks can cause expansion of

hull. Other problems include whirling of tail shaft, relative movement of the

hull and misalignment due to droop from propeller weights. Deformation produced

by the thrust load can cause misalignment problems, unless suitable stiffening

is employed (particularly with an end of gearbox installation).

Support :-

The substantial double-bottom structure under the main machinery provides an ideal foundation for the thrust block and is the reason for siting the thrust block close to the engine. The upright thrust block and any supporting stool must have adequate strength to with stand the effect of loading which tends to cause a forward tilt. This results in lift of aft journal of the block and misalignment of the shaft. Axial vibration of the shaft system, caused by slackening of propeller blade load as it turns in the sternframe or by the play of diesel engine crankwebs, is normally damped by the thrust block. Serious vibration problems sometimes cause thrust block to rock, panting of the tanktop and structural damage.