QUESTION.

Sketch and describe a collosion

bulkhead

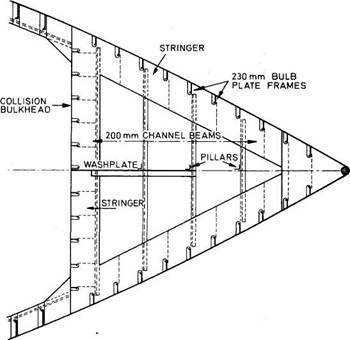

PANTING STRINGER Fig. a

In the fore peak, side stringers are fitted to the

shell at intervals of 2 m below the lowest deck (Fig. a). No edge stiffening is

required as long as the stringer is connected to the shell, a welded connection

being used in modern ships. The side stringers meet at the fore end, while in many

ships a horizontal stringer is fitted to the collision bulkhead in line with

each shell stringer. This forms a ring round the tank and supports the bulkhead

stiffeners. Channel beams are fitted at alternate frames in line with the

stringers, and connected to the frames by brackets. The intermediate frames are

bracketed to the stringer. The free edge of the bulkhead stringer may be

stiffened by one of the beams. In fine ships it is common practice to plate

over the beams, lightening holes being punched in the plate.

The tank top is not carried into the peak, but solid

floors are fitted at each frame.

Fig. shows the construction of a collision bulkhead.

These floors are slightly thicker than those in the

double bottom space and are flanged on their free edge. The side frames are

spaced 610 mm apart and, being so well supported, are much smaller than the

normal hold frames. The deck beams are supported by vertical angle pillars on

alternate frames, which are connected to the panting beams and lapped onto the

solid floors. A partial wash-plate is usually fitted to reduce the movement of

the water in the tank. Intercostal plates are fitted

for two or three frame spaces in line with the centre girder. The lower part of

the peak is usually filled with cement to ensure efficient drainage of the

space.

Between the collision bulkhead and 15% length from

forward the main frames, together with their attachment to the margin, are

increased in strength by 20%. In addition, the spacing of the frames from the

collision bulkhead to 20% of the length from forward must be 700 mm. Light side

stringers are fitted in the panting area in line with those in the peak. These

stringers consist of intercostal plates connected to

the shell and to a continuous face angle running along the toes of the frames.

These stringers may be dispensed with if the shell plating is increased in

thickness by 15%. This proves uneconomical when considering the weight but

reduces the obstructions to cargo stowage in the hold. The peak is usually used

as a tank and therefore such obstructions are of no importance.

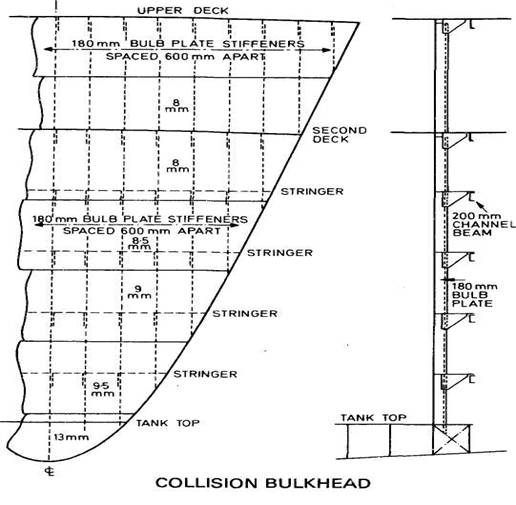

The collision bulkhead is stiffened by vertical bulb

plates spaced about 600 mm apart inside the peak. It is usual to fit horizontal

plating because of the excessive taper on the plates which would occur with

vertical plating.

Fig. shows the construction of a collision bulkhead.

The structure in the after peak is similar in

principle to that in the fore peak, although the stringers and beams may be

fitted 2.5 m apart. The floors should extend above the stern tube or the frames

above the tube must be stiffened by flanged tie plates to reduce the

possibility of vibration.