Question

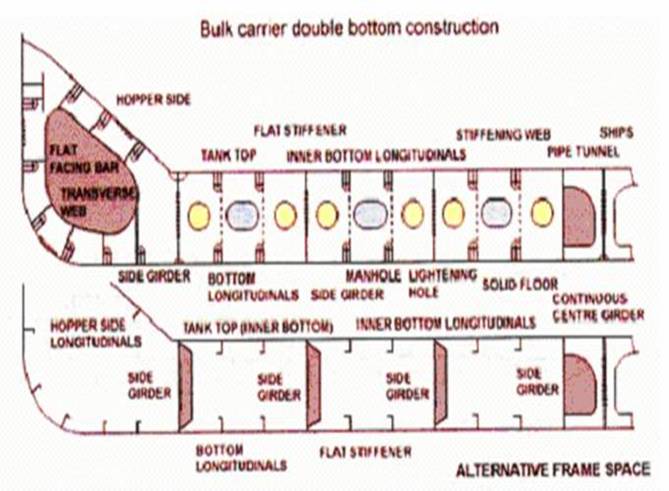

Sketch a cross section of a bulk carrier

with either deep or shallow D.B. showing the types of framing used

Describe the corrosion problem experienced

with ballast tanks

State how such tanks are protected against

corrosion.

With the reduction in the number of new ships built,

the older vessels in service have extended lives and these have shown some

severe corrosion problems in ballast tanks. The problems are made

worse by the neglect of maintenance and the use of thinner^ scantling when high

tensile steel is used. The most serious problems ha^.e been found in permanent ballast tanks.

Galvanic corrosion can rapidly eat into the structure and rates increase with

temperature and differential aeration (bottom of the tank is lower in oxygen

concentration and hence anodic to die top).

The presence of sulphate

reducing bacteria, cause further microbiological degradation.

The muds of some river beds

are particularly rich in SRB. The bacteria can cause local pitting which has

been known to penetrate the bottom shell.

Protection of ballast tanks is by complete paint

coatings supplemented by sacrificial anodes. Some older ships have main anodes

and booster anodes. The booster anode have large

surface area to volume ratio (flat discs) causing rapid cation

formation at cathode (steelwork) which cleans the surface of rust and

scale. A protective film is 'formed but this can quickly be removed in

surface therefore a main anode which has a large volume to surface area ratio

(hemispherical) are fitted and should last about 3

years.

Hydrogen gas is formed on the cathode (steelwork) of

the tanks, hence the tanks should be pressed up to

prevent the formation of hydrogen gas pockets in the vapour

space of slack tanks. The tank venting system should be operational

when emptying the ballast tank with precautions taken as for a low flash point

cargo. The tank should be considered non gas

free until tested.

Ballast tanks that have been empty for some time may

have atmospheres deficient in oxygen which is consumed in the corrosion

process. Deaths of crew entering such spaces have occurred (see

M.910) therefore the tank must be fully vented before entering and 'Entry to

enclosed spaces' procedures

observed.

Maintenance includes cleaning and re-coating with pits

filled or welded: Serious corrosion over an extensive area would

need plate renewal.