Question

Describe the

effect on GM of rolling and how bilge keels, anti rolling tanks and stabilizer

fins reduce the amplitude of rolling.

The natural

rolling period of a ship maybe estimated by the formula:

2πk/√gGM seconds

Rolling period P=† †††††††

where

GM is the metacentric height

k

is the radius of gyration of the loaded ship about a longitudinal polar axis.

Thus a large metacentric height will produce a small period of roll,

although the movement of the ship may be decidedly uncomfortable and possibly

dangerous. A small metacentric height will produce a

long period of roll and smooth movement of the ship.

The simplest form of stabilization, bilge keels, are often fitted even

when other more sophisticated methods of roll reduction are used. Cheap and easy

to maintain, they can provide up to 30% roll amplitude reduction and are

effective when a ship is at rest or making headway.

These stabilizes

use the movement of slack liquid in a tank to produce a moment in opposition to

the rolling, moment. Since the liquid, in the tank, is a separate mass

from the vessel it will possess different inertia. When the vessel rolls,

there will be a time lag before the water begins to-move in the same direction.

If the water movement in the tank can be controlled so that it is

continuously out of phase with the movement of the vessel, then there will be

an anti-roll moment

The tank system to control

the water movement may be one of three types, namely;

Pure

Passive in which the movement of water is controlled by vertical or horizontal

restrictions such as baffle plates or manually operated valves.

Controlled Passive in which

the water movement is controlled by air or water valves

acting in response to a roll sensing device such as a gyro.

Active Controlled in which

the water movement is aided by the addition of an impeller

or pump. Large masses of water need to be moved

continually which requires high power. Initial high cost together

with higher maintenance make this an expensive system.

Control is again related to a roll sensing

device such as a gyro.

Anti-heeling tanks

Container ships and RO-RO

(roll onóroll off) vessels are usually fitted with anti-heel tanks which enable

the ship to be kept upright during uneven loading of cargo. Transfer of liquid

from one tank to the other is by pump or compressed air.

Controlled passive system

stabilizing tanks are used in the anti-heeling arrangements of some ships. The

simplest method in this scheme, for transferring the liquid, makes use of

compressed air admitted to the top of either tank, to force the liquid from one

to the other.

FIN STABILISERS

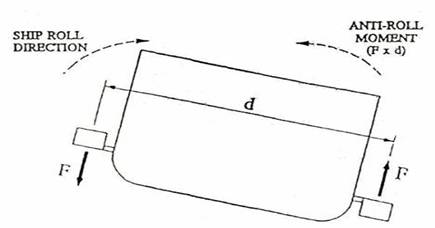

This system consists of

fixed or retractable fins fitted port and starboard, ideally at the point of

maximum beam and with the fin axes intersecting the round of bilge in line with

the ships rolling centre.

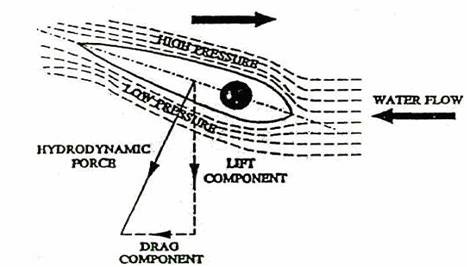

The fins are aerofoil in

shape, similar to a rudder, and produce a hydrodynamic force when turned to an

angle to the flow of water. As the water flows around each fin, pressure

differences are created, generating a force with an

vertical component (lift) and a longitudinal component (drag). The fins are

fitted port and starboard at about bilge keel level in the midship

region of the ship so that forces generated give a maximum couple to oppose

rolling

†