Question

(a) With

reference to the underwater surface of the hull:

(i) describe a hull plate roughness analyser system;

(ii)

State the significance of the roughness profile and compare the typical

roughness values for a new ship and a ship eight years old;

(b) With

reference to the application of self polishing paint in dry dock:

(i) describe the plate preparation necessary;

(ii)

State the defects that may occur in the paint coating if it is not

correctly applied;

SOLUTION.

(a)(i) The Instrument used

for hull plate roughness measurement may be the BMT Hull Roughness Analyser (HRA) or some similar instrument The HRA has a

portable microprocessor with a digital print out and display.

The computer, is connected to

a hand held carriage having a stylus measuring head. The head is moved over the

hull surface and the stylus traces the hull roughness.

The short wave roughness cut off is the diameter of

the stylus tip, whilst the long wave cut off has been selected as 50mm. One

traverse of the head at any point on the hull will gather information from

approximately ten sample lengths of 50mm. For each 50mm sample, the micro

processor will assess the mean gradient through the peaks and valleys and give

the highest peak to lowest valley measurement in that sample. This measurement

is called Rt (50)

The roughness survey needs to be thorough and will

cover approximately 100 selected locations around the hull. Care is taken to give a representative

sample of bow, stern, midships and boot topping.

Damaged areas should not be; under or

over-represented. At each of the stations, a number of traverses of the

carriage will give 'n' readings of RRt(50). The 'mean hull roughness' (MHR) at that station is the average

of the Rt(50) readings.

i.e.

MHR = ERt(50) \n

There will be

'm' stations around the hull and the 'average hull roughness' (AHR) will be

the average of MHR at each station.

i.e. AHR ;= E MHR \ m

The survey is-carried out when:

New .

gives

a reference value

In dock -

after washing, but before maintenance procedures to give deterioration

Undocking - gives a comparative measure after

maintenance

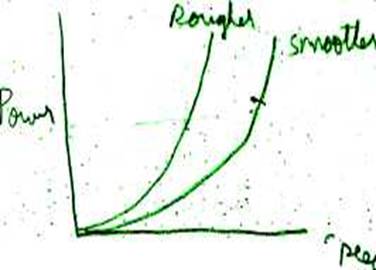

(ii) The significance of the roughness profile is that

the factional resistance of the ship (which is the major resistance for

merchant ships) will increase and thus power and fuel consumption will increase

for a particular speed. Typical roughness value (AHR) for a new ship is

approximately 120Um. Since deterioration is around 20 to 40 Um per year, then a

ship eight years old-will have an AHR of approximately 300 to 400Um.

![]() (b)

(b)

The effectiveness of the paint protection is dependent

upon the plate preparation necessary prior to the application of the self

polishing paint. The best preparation is

grit blasting which cleans the hull to the bare steel and provides a surface

finish for the paint to 'key' to.

Paint is normally applied by airless spray.

The defects that may occur in the paint coating if it is not correctly applied include sagging, runs, drips, thinness, overspray and poor surface texture ('orange peel' effect).