Question

(a) With reference to the membrane tanks for

the carriage of liquefied gas at very low

temperatures:

(i)

Describe with the aid of a sketch ONE method of building up the

insulation;

(ii) State with reasons the alloy which is

used for the membrane;

(b) Describe with the aid of a sketch how

tanks are located and supported

Longitudinally

Transversely

Explain why a secondary barrier is installed

Answer.

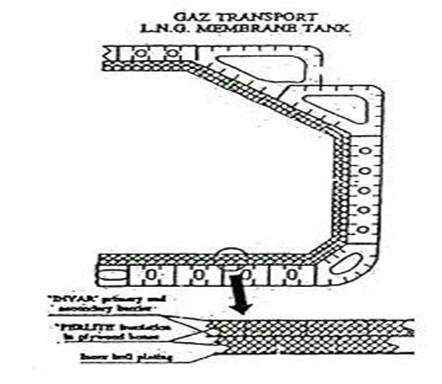

(The answer is basic upon the 'Gas Transport' system)

(a)(i) The inner

hull has plywood boxes, filled with granulated periite insulation,

attached in two layers. An invar secondary

barrier is fitted between the layers, and a primary

invar barrier separates the gas from the insulation

(ii) Membrane systems must have a complete secondary

barrier to ensure integrity. The membrane material is very thin (0.5 to 1.2mm)

and must be capable of coping with the thermal expansion/contraction involved

with a very low temperature cargo. This is achieved by use of a material with a

very low coefficient of thermal expansion, (e.g, INVAR steel - 36%Ni steel).

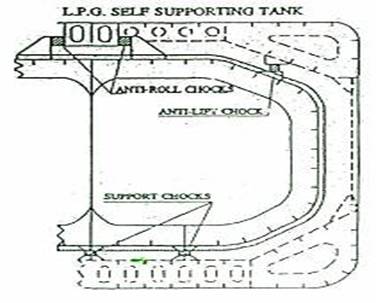

(b) These tanks may also be referred to as

'independent' or 'self, supporting'. They do not form part o the ships hull and

do not contribute to the strength of the ship. They can be spherical,

cylindrical or prismatic in shape. Prismatic tanks are stiffened internally

by wash bulkheads, webs, girders and stiffeners, in a similar manner to oil

tankers.

Whilst the tanks are independent of the ships

structure, the tanks must resist the dynamic forces imposed by the ship motions

and this is achieved by 'chocks' such as: support chocks, anti-roll chocks,

anti-pitch chocks and anti-lift (float) chocks.

The chocks must also be a thermal barrier between the

hull and the cargo and may be wood (plywood) or plastic (permali).

Explain why a secondary barrier is installed

Secondary barriers are required if the minimum temperature is less than -10°C. Thus, in the event of leakage from the primary container, the liquid or vapour is contained for a period of up to 15 days. If the minimum temperature is higher than -50°C, the ship's hull may be used as a secondary barrier if constructed of Arctic D steel or equivalent. Independent secondary barriers may be of nickel steel, aluminium or plywood as long as they can perform their function.