Question

Describe a method for attachment of bilge keel

State 3 reasons for not extending bilge keel to the

entire length of the vessel

Explain 2 principle of roll damping that bilge keel

exploit

Answer.

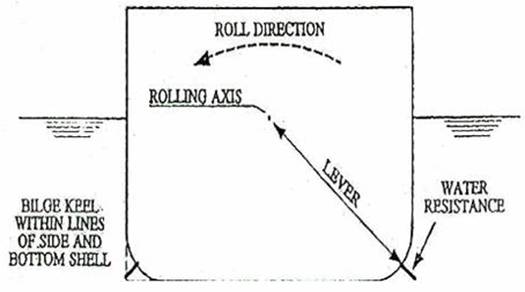

A bilge keel consist of a projection from the turn of

bilge over 30% to 50% of the ships length in the midship

region. To help prevent damage to the bilge keels they are fitted within the

lines of bottom and side shell. To be effective the keel should however project

beyond the boundary layer.

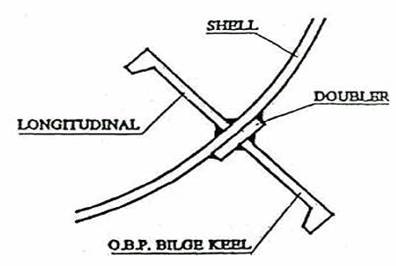

The bilge keels are attached directly in line with an

internal stiffening member such as a girder or longitudinal. On thicker shell

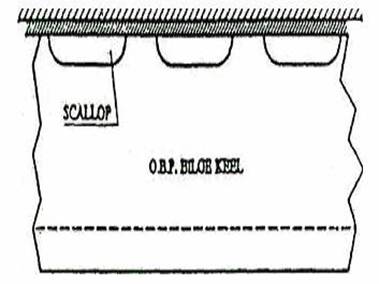

plating (such as merchant ships) the bilge keel is made up of a flat bar doubler welded directly to the shell and an offset bulb

plate (OBP) with scallops cut in it is welded to the flat bar doubler. The ends of the bilge keels are tapered and if the

keels are positioned so that they follow the streamlines at the service speed

of the ship, then the added resistance is only about 2%.

If the keel is fitted for the full length of the

vessel it would be more difficult to construct and would be difficult to align

with flow along the hull, particularly at the fore end, causing a large

increase in resistance and fuel consumption. At the aft end, the boundary layer

is much thicker and since the keel would not project through, it would have

limited effect.

The simplest form of stabilisation, bilge keels, are often fitted even

when other more sophisticated methods of roll reduction are used. Cheap and

easy to maintain, they can provide up to 30% roll amplitude reduction and are

effective when a ship is at rest or making headway. Fitting the bilge keel to

the parallel mid-body means that it is a simple construction and gives the best

damping effect since it maximises the lever to the

axis of rotation.

A 'full form ship has a higher

natural damping coefficient than a Tine' form ship. Thus, a bilge keel fitted

to a full form ship will have less effect-than on a fine form. Furthermore,

since the bilge keel must be between the lines of side and bottom shell, it

will be constrained to a smaller size on full

form ships.