Question

(a)

An M. notice draws attention to the need for adequate support, of engine

room gantry cranes.

(i) Sketch sections' through the engine room

casing showing how the crane is supported by the ship structure

(ii).

State what restricts the forward and aft limits of the crane and what is

fitted to prevent the crane damaging the forward and aft bulkheads of the

casing

State the Chief Engineers responsibilities

for the engine room gantry crane as laid down by the Code of Safe Working

Practices for Merchant Seaman.

Answer

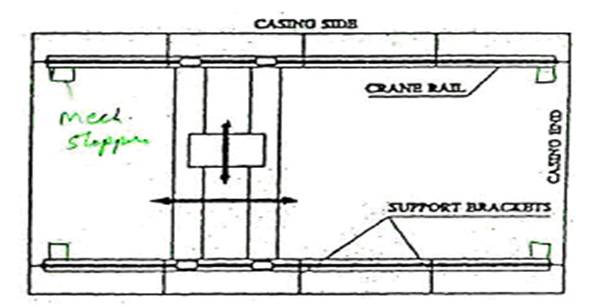

A gantry crane is usually fitted in the engine room of

most medium and large size ships to allow for the removal of machinery parts

for inspection, maintenance and repair. Typically an overhead gantry crane of 5

tonne SWL is installed to cover the full width, and

to travel the full length of the casing.

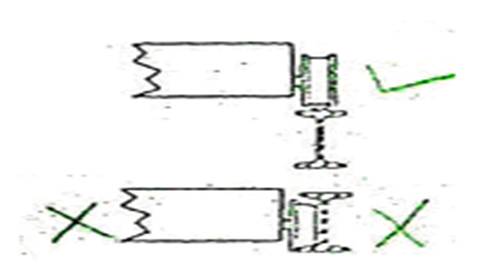

The crane usually runs on rolled steel joist (RSJ)

rails having a rail bar welded on top.

(Earlier types of engine room gantry cranes had 4

tapered wheels that fitted into the inside flanges of the RSJ but a fatal

accident occurred when deflection of the beams was sufficient to cause the

crane to fall into the engine room - see M.588)

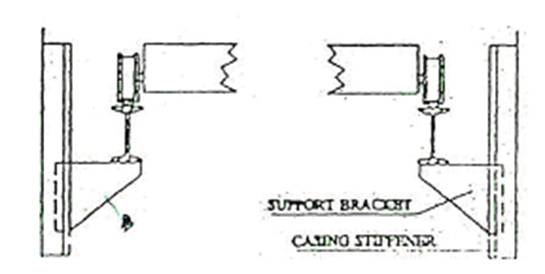

The cranes are supported at each end by brackets tying

them to stiffeners at the ends of the. casing, whilst

intermediate brackets extend from the casing side to restrict deflection of the

beams.

(ii) The

limit of forward and aft travel is the end bulkheads of the casing. Stops are

fitted at the ends of each rail track to prevent the crane colliding with the

casing end.

(b) Chapter 17

of the Code of Safe Working Practices for Merchant Seaman covers the

responsibilities of Master and Employer, but the Chief Engineer would have the

initial responsibility for the proper operation, maintenance and documentation

of the crane.