Question

Describe the

arrangement of tank top and double bottom in the machinery space making

particular reference to the structure and scantlings below the main engine.

Show the method adopted in the arrangement of D.B. tanks to avoid contamination

of fresh water, fuel oil and lube oil stored in D.B. tanks.

Answer

Double bottom in the

machinery space

In the machinery space other

factors must be taken into account. Forces of pulsating nature are transmitted

through the structure due to the general out of balance forces of the machinery

parts.

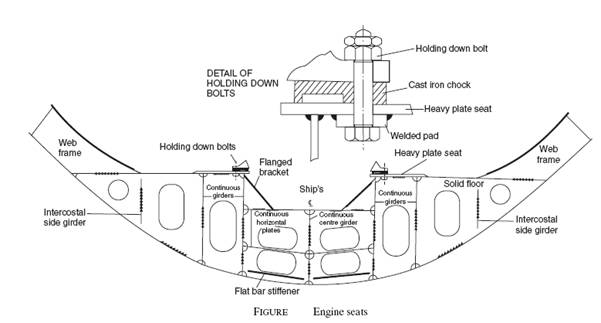

The machinery seats must be

extremely well supported to prevent any movement of the machinery.

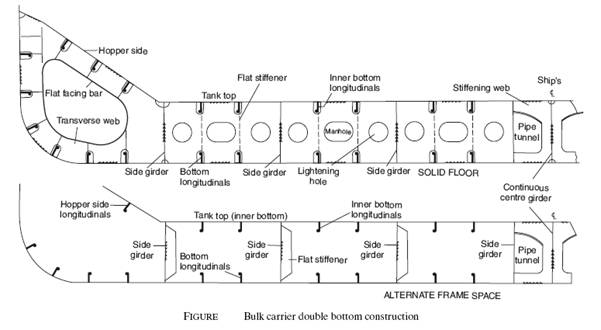

Additional girders are

fitted in the double bottom and the thickness of the tank top increased under

the engine in an attempt to reduce the possibility of movement which could

cause severe vibration in the ship. For similar reasons the shaft and propeller

must be well supported.

Great care must be taken in

the machinery space to ensure that the main and auxiliary machinery are

efficiently supported. Weak supports may cause damage to the machinery, while

large unsupported panels of plating may lead to vibration of the structure.

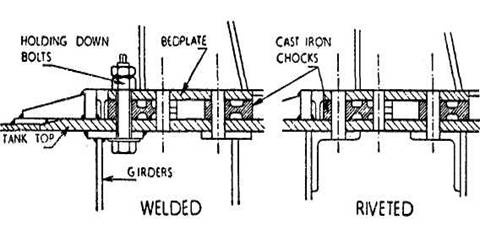

The main engine bedplate is

bolted through a tank top plate which is about 40 mm thick and is continuous to

the thrust block seating.

A girder is fitted on each

side of the bedplate in such a way that the holding down bolts pass through the

top angle of the girder.

In welded ships a horizontal

flat is sometimes fitted to the top of the girder in way of the holding-down

bolts.

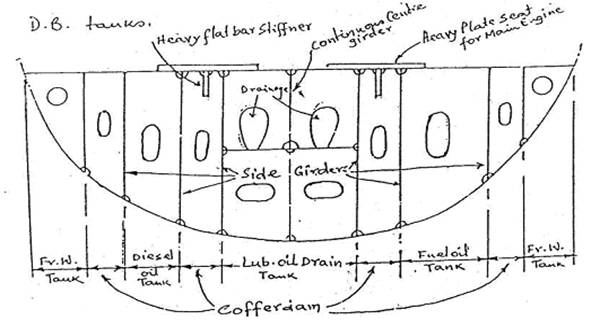

In motor ships where a drain

tank is required under the machinery, a cofferdam is fitted giving access to

the holding down bolts and isolating the drain from the remainder of the double

bottom tanks.

Additional longitudinal

girders are fitted in way of heavy auxiliary machinery such as generators.

Access to these D\B tanks

and cofferdam is provided by watertight manhole door.

Docking plugs are fitted in

all D\B yanks for complete draining in drydock for

purpose of inspection

Air pipes and sounding pipes

are also fitted to D\B tank and these tanks are tested by maximum service pressure head