Question

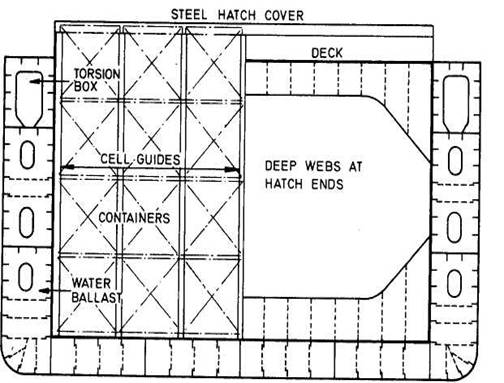

Sketch a transverse section

through the hold of a container ship’ referring to the sketch describes how

adequate structural strength is built into the hull

Because of the wide hatches

the deck plating must be thick, and higher tensile steel is often used.

The deck, side shell and

longitudinal bulkheads are longitudinally framed in addition to the double

bottom.

The hatch coamings may be continuous and therefore improve the

longitudinal strength. Problems may arise in these vessels due to the lack of torsional strength caused by the large hatches.

This problem is overcome to

some extent by fitting torsion boxes on each side of the ship.

These boxes are formed by

the upper deck, top part of the longitudinal bulkhead, sheerstrake

and upper platform, all of which are of thick material.

The boxes are supported

inside by transverses and wash bulkheads in addition to the longitudinal

framing.

These boxes are only

effective if they are efficiently tied at their ends. At the after end they

extend into the engine room and are tied to deep transverse webs.

Similarly at the fore end,

they are carried as far forward as the form of the ship will allow and are

welded to transverse webs.

The longitudinal bulkheads

below the box may have to be stepped inboard to suit the shape of the ship, the

main longitudinal bulkhead being scarped into the stepped section.

At the ends of the hatches

deep box webs are fitted to increase the transverse and torsional

strength of the ship.

These webs are fitted at

tank top and deck levels. Care is taken in the structural design at the hatch

corners to avoid excessive stresses.

The double bottom structure

beneath the cell guides is subject to impact loading as the containers are put

on board. Side girders are usually fitted under the container seats with

additional transverse local stiffening to distribute the load.

Unlike normal cargo ships in

which the cargo is distributed over the tank top, the inner bottom of a

container ship is subject to point loading.

The double bottom must be

deep enough to support the upthrust from the water

when the ship is deeply loaded, without distortion between the container

corners.