Question

With reference to a 3speed a.c. cage motor driven

cargo winch

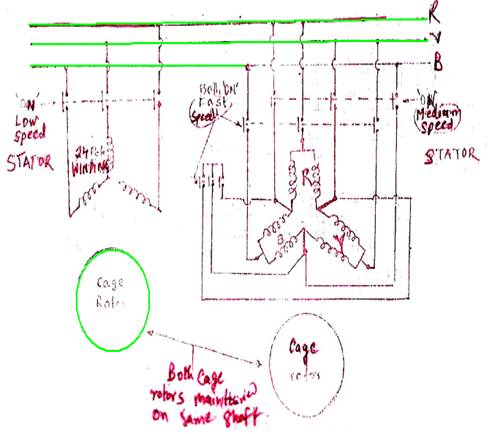

Sketch a circuit diagram for a pole change motor

Describe how speed change and braking are achieved

Answer.

Three speed pole changing winch motor employ dual motors in

which one cage rotor operating in a stator wound for say 24 poles gives a low

speed where as other cage rotor operating in a pole amplitude modulated stator

wound for say 8 poles to give medium speed and 4 pole to give high speed

The low speed 24 pole stator winding has a single winding per

phase and for low speed operation the stator contactor closes and provides

power supply to the winding when all the contactors are kept open

For medium and high speed operation the pole amplitude

modulated stator has two windings in each phase with a centre lap. One stator

contactor gives supply such that phase winding are in service and 3phase

winding are in delta which makes 8poles and medium speed operation

For high speed operation another two contactor comes ‘ON’,

such that phase winding are in parallel and 8phase windings are in star, which

makes 4poles.

For reversing operation two phase winding are interchanged by

other contactors.

Braking of winch motor

For a 3 phase , 50 Hz supply the

speed of induction motor at 4pole would be about 1400RPM, at 8poles 700RPM, and

24 pole about 200 RPM.

First step slow speed is used for breaking out and decking

second step medium speed is used for handling heavy loads and third step high

peed for normal loads

The lowering speed are slightly higher than those for lifting

as the speed of an induction motor rises slightly when changing over from

motoring to regeneration

For braking winch motor disc operated electromagnetic brakes

are employed. The disc brake is D.C. operated through srlenium

cell rectifiers and is provided with a hand release so that loads may be

released under control in case of a power failure

An independent foot pedal operated brake is also provided

When switching back to the ‘OFF’ position the 24 pole step is

brought in before the brake is applied so that when braking heavy loads the

wear on the magnetic brake is reduced to a minimum

However for luffing and slewing

operation sometimes dynamic braking is employed before magnetic brakes are used

In dynamic braking D.C. supply is injected into the stator

winding just prior to switching off

This has the effect of producing a static field in the stator

Rotation of the stator induces an emf

in the rotor winding and the interaction of the stator field and rotor current

produces torque which opposes the rotating braking power being dissipated in

the form of heat in the rotor winding and in stator from losses

The effectiveness of the method can be adjusted to the

requirement of the carne by adjusting the D.C. voltage

When the crane comes to rest the magnetic brakes are applied

and the D.C. fed to the motor is switched off.