Question.

What is open and close loop

Discuss the relative advantages

Sketch a practical close loop system and describe the loop

explaining the term servomotor feed back sensor element

An open-loop control system is one without monitoring

feedback of the value of the controlled parameter.

A closed-loop control system possesses monitoring feedback,

the deviation signal formed as a result of this feedback being used to control

the Action of the final control element in such a way as to reduce the

deviation to zero.

OPEN-LOOP - They are simple. Their accuracy is determined by

the calibration of their elements. They are not generally troubled with

instability

CLOSED-LOOP: They are highly accurate. They are more

complex. Non-linearities and distortion are greatly

reduced. They have wide bandwidth. They suffer from instability problems.

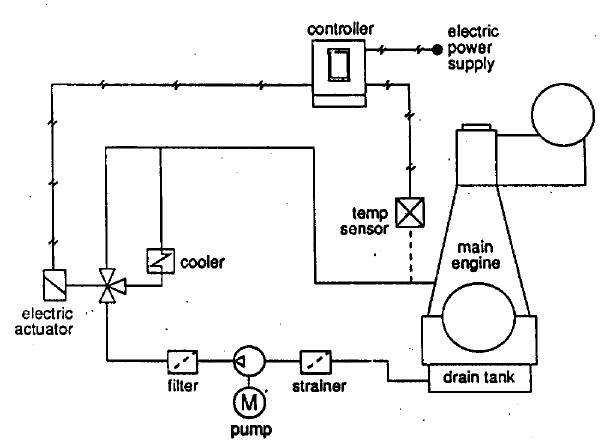

Operation

of a closed-loop circuit (Fig)

The

temperature of the lubricating oil for a main diesel engine has to be

controlled to prevent it rising to a level at which the oil viscosity becomes too

low for effective lubrication.

In

order to achieve this oil is cooled by passing it through .a water-cooled heat

exchanger.

Low

oil temperature and the resulting high viscosity could prevent adequate flow of

oil to the engine so the control system has to regulate the temperature of the

oil entering the engine to an approximately constant value

For

an electrical/electronic system to control oil temperature the measuring device

could be a platinum resistance coil feeding its signal directly into a proprietary

electronic controller with an electric output signal to a motor which positions

the three-way valve determining the proportion of oil flow to pass through the

cooler.

With

the system in a steady state the three-way valve will be positioned so that the

cooler dissipates heat from the oil at exactly the same rate as that at which

the engine is heating the oil.

If

the engine conditions, speed or load change, or the water temperature or flow

rate in the cooler vary, the valve will have to adopt a different position to

restore the balance of heat flow and maintain the required oil inlet temperature

at the engine.

Feedback occurs in automatic control systems when the

control action depends upon the measured state of the machine or process being

controlled. Feedback gives and automatic control system the ability to deal

with unexpected disturbances and changes in the plant behaviour.

SERVO-MOTORS.

Is the final control element present in servo mechanism or

control system

The servo may be electrical, pneumatic, or hydraulic

operated

May be rectilinear or rotary; operated by air, fluid or

electricity; applied in either process or kinetic control systems.

Sensor or Detecting Element

In a closed-loop control system, this is the component that

translates the physical process variable into a measurement (the measured

variable) that is used within the controller.

The Controlled Condition is the temperature of the

lubricating oil, and this is monitored by a sensor or Detecting Element, which

could be a filled systems thermometer connected to a Bourdon tube. This

operates a nozzle/flapper device which produces a pneumatic signal, known as

the Measured Value, which is directly related to the temperature of the

lubricating oil.