Question

With

reference to electronic control systems:

(a)

Draw a simple block diagram for temperature control;

(b)

Describe each component shown in the diagram in (a).

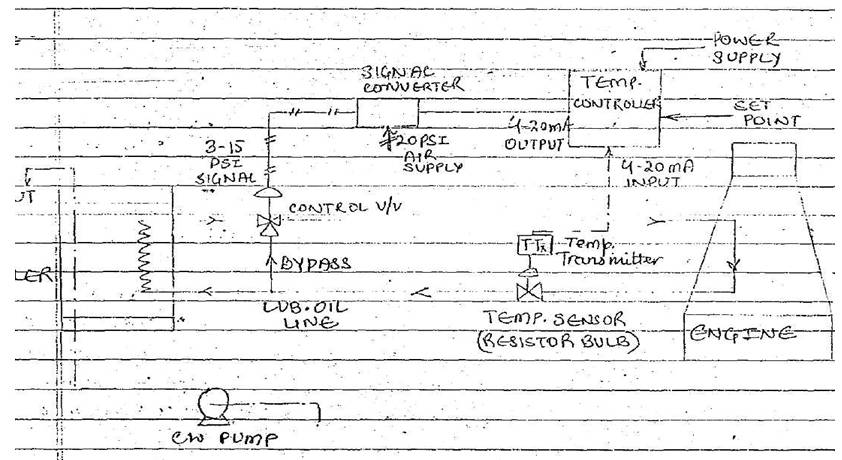

Control scheme

The hot oil coming out of the engine is sent to a cooler

where cooling water is continuously circulated by a pump.

The cooler outlet oil line has a 3 way valve [pneumatic

control] for manipulating the quantity of oil through the cooler.

The control valve outlet line is connected to the engine oil

inlet port. A temperature sensor, usually a RTD [resistance temperature

detector] is fitted on the engine oil outlet line to measure temperature

The RTD gives a change of resistance output proportional to

temperature.

This signal is converted into a standard 4-20mA current

signal in the transmitter and fed to the controller

The controller compares the signal with the set point

and based on the error (measured temperature set point) gives an output of

4-20mA range

The current output is converted into corresponding 3-15PSI

pneumatic signal in the signal convertor and fed to the control valve so as to

regulate the oil flow through the cooler. The 3 way control valve is used so

that if sensed temperature is higher, most of the oil will go via bypass and

minimum will flow through the cooler.

The Instrument Component Used In The Scheme are explained as follows

Temperature

sensor.

An RTD is used to detect

temperature

This is made up of a coil of

platinum wire over mica strip and encapsulated in ceramic or SS enclosure for

mechanical rigidity

The resistance of this coil changes

with temperature in linear relation

The change in resistance is

indicative of temperature.

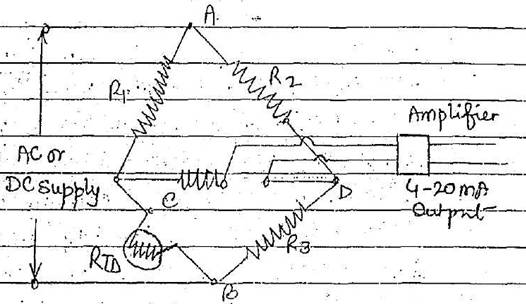

Temperature transmitter

The RTD change in resistance can be

detected by a Wheatstone bridge circuit and a corresponding output current of

4-20mA is generated in the transmitter

The Wheatstone bridge circuit

consist of 4 arms as shown

Across A & B, the bridge supply

is given R1, R2, And R3. is

chosen based on instrument calibration range and RTD is connected to 1 arm

Across C & D the current changes as RTD resistance changes.

This is amplified and adjusted to

4-20mA corresponding to temperature change.

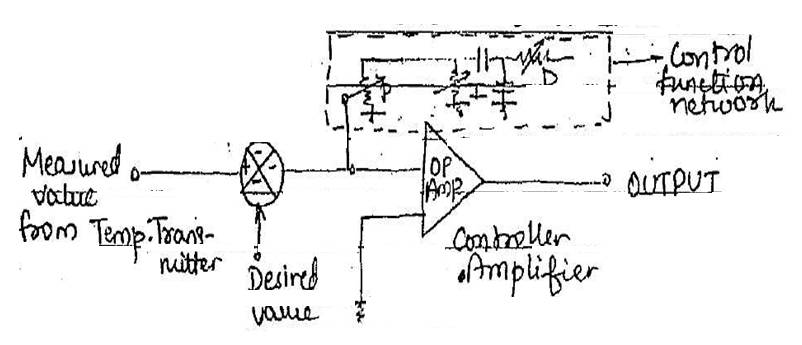

Controller.

The electronic controller can be an

on / off or continuous controller using P+I+D logic. It has a main power and

receives 4-20mA input from transmitter. The desired value of temperature is set

as set point in it.

The controller compares the actual

value and the set point and based on error [difference between actual and set]

generates an output [4-20mA] depending on the P,I,D.

SETTING

The Out Put Generated In The

Controller Will Be In Such A Direction [ Increasing

Signal Or Decreasing Signal] So As To Move The Control Valve To A Position Of

Balance, i.e. The Oil flow through cooler and bypass manipulated to make the

measured temperature equal to set point

In other words the controller keeps

acting till the error becomes zero.

Signal converter.

For ease of use and maintenance a pneumatic

control valve is generally preferred. It requires a control signal of 3-15PSI

air signal

Since electronic controller gives a

4-20ma current output, a signal converter is used to change this into a

proportional 3-15PSI air signal. The signal converter uses the principle of

mutual induction in creating movement of core when current through the coil on

it changes

The physical movement is

mechanically linked to a flapper / nozzle mechanism to generate 3-15Psi pneumatic

signal, hence 4-20mA current signal gets converted to

3-15PSI air signal.

Control valve. The pneumatic

control valve is a 3way valve. The main parts connected between cooler and

engine inlet while the bottom part is a bypass passage between cooler inlet and

outlet. The control air signal [3-15PSI ] acts on a

diaphragm against a calibrated spring and causes linear movement proportional

to signal. The stem carries the plugs that move against the seat rings varying the

opening of ports

At extreme positions only one port

is open, the other closed. The control signal manipulates the relative opening

of he two ports. The valve can be fitted with a valve positioner

to enhance speed of operation and better stability of stem. Valve positioner will need a separate setting of air supply that

can be given through an air regulator.