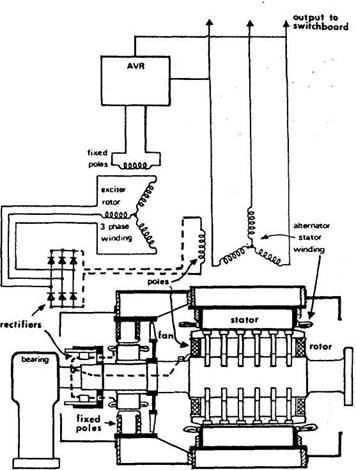

Brushless alternator

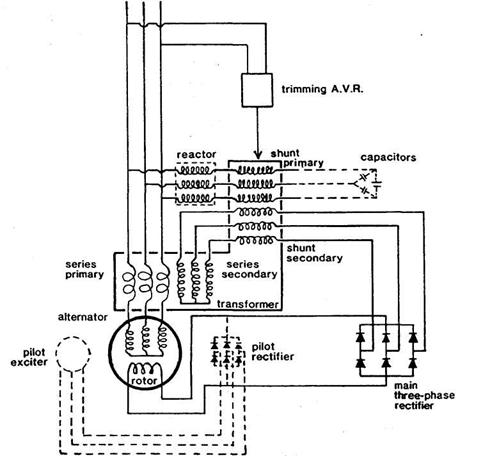

Self-Excited

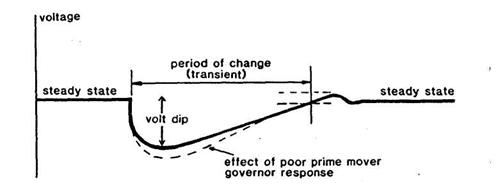

Error Operated A.C. Generator

switchboard

Static excitation system principle

Excitation of

self excited brushless a.c generator

This type of generator is the most common type used on

modern ships.

1. The main rotor has residual magnetism

which produces a weak magnetic field.

2. So when the rotor turns, this weak

field flux cuts the main stator winding.

3. A low voltage is generated in the main

stator.

4. This output is fed back to the AVR

which rectifies the a.c. power to d.c.

5. This

6. A stationary magnetic field is created

in the exciter stator by the

7. The exciter rotor, when it rotates,

cuts this stationery field.

8. Since the exciter rotor windings are

wound to produce 3 phase a.c. power, 3 phase a.c. is generated in it.

9. All of this 3 phase a.c.

is led to a bank of rotating diodes mounted on the same shaft.

10. The diodes convert all of this a.c. to d.c.

11. This d.c is the

“excitation” of the main generator.

12. This

13. So the total field flux produced by the

generator rotor is now increased: field flux due to current feedback from AVR

& field flux due to residual magnetism.

14. Since more flux now cuts the generator

stator windings, a higher voltage is generated.

15. This process of voltage build-up

continues until the generator rated terminal voltage (usually 440V) is

reached. The AVR regulates the voltage

to this value.

b)

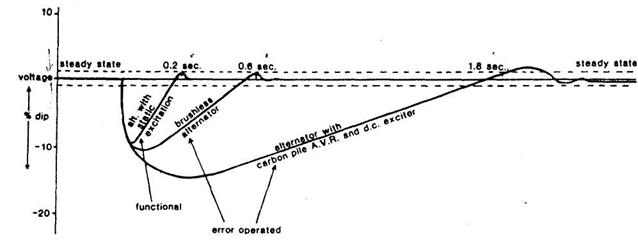

Both

the 'conventional' alternator with

The

voltage has to change for the AVR to register the deviation from normal and to then adjust the excitation

for correction.

The

suddenness of the initial volt dip (blamed

specifically on transient reactance) is such that the response from the error-operated system cannot come until

the dip is in the second slower stage.

Thus

neither machine can prevent the rapid and vertical volt dip due to transient

reactance, but the faster acting voltage

regulator of the brushless machine will arrest the voltage drop sooner on the slower secondary part of

its descent.

The

carbon pile regulator is slow compared with the static type but better recovery by the

brushless alternator is also achieved by field forcing, i.e. boosting the excitation to give a

quicker build-up.

AVR will control generator voltage to ± 2.5% [or better] of it’s set value over the load range.

This is the steady state voltage regulation.

Transient voltage dip is usually limited to 15% for a

specified sudden load change with recovery to rated voltage with in 1.5

seconds.

Typical volt dip/recovery pattern for an alternator

Voltage dip

recovery for brushless alternator [error operated]