Question.

What are routine maintenance carried out on an a.c. motor and

Explain the meaning of single phasing in a.c. machinery

State the dangers associated with single phasing

& enumerate the protective devices normally fitted to counteract such

dangers.

Answer.

The maintenance requires that for cage rotor

induction motor are very simple. Keep insulation resistance high, contact

resistance low, lubricate correctly, maintain even air gap, ensure both the

interior and exterior are always clean and dry.

All running a.c motor is

to be felt by hand to check for overheating. Check current drawn is within

limits. Check that there is no vibration and is running smooth. Regularly clean

the external surface of the motor. Periodically grease all running motor

bearing with correct quantity and type of grease recommended by manufactures.

Check brush gap and slip ring. The shaft of

stationary motor should be periodically rotated quarter turn to minimize

vibration damage to the bearing. Periodically Check insulation, tightness of

terminals, connection and foundation bolts, bearing

removed as per PMS.

Check for damage renew if necessary, stator and

other motor control gear regularly inspected to check and maintaine

following items.

Enclosure – check for accumulation of dirt and

rust, any corroded parts must be cleaned and painted, examiner startor fixing bolt and earth connection

Contactor and relay – check for any sign of

overheating and loose connections, remove dust and grease from insulating

components. Ensure magnet armature of contactor moves freely.

Contacts – examine for excessive pitting and

roughness due to burning. a thin smear of electrical

contact lubrication helps to prolong life of all contact. Check contact spring

pressure. Check power and control fuse contact.

Connections - examine all power and control

connection for tightness

OCR - check for proper size (relate to motor full

load current) periodically overhaul motor.

Following safety precaution should be observed.

Take permission from responsible officer for doing

specific work.

Make sure to switch off supply from both ends.

Place caution danger notice near the work place and near switching terminals.

Badly contaminated motor requires total immersion

in solvent. Care is taken because it is toxic, ample ventilation should be

provided.

Check bearing cover, if damaged or crack should be

replaced.

Stator winding look for damaged insulation. Examine

stator core for signs of rubbing with rotor. Check I.R. rotor inspected for

sign of damage or overheating in cage winding and laminated core. Clean all

ventilating ducts. Internal fans must be in good condition to provide adequate

venting.

b) [Single Phasing is where one of the 3-phase's

supplying the Motor becomes disconnected.

The Motor will continue to run if this happens and

can result in Motor Burnout.

The effect of Single Phasing is to increase the

Current in the two remaining Lines and cause the Motor to become very noisy due

to uneven Torque produced.]

1) The meaning of single phasing is where one of

the three phases is lost in an AC motor.

2) The effect of single phasing is an imbalance in

the other two phases, which can lead to rough operation of the motor, or if the

motor is stopped and you try starting the motor, it will make a humming noise

and will not start.

Protection against single

phasing.

Thermal overload

Single phase preventer

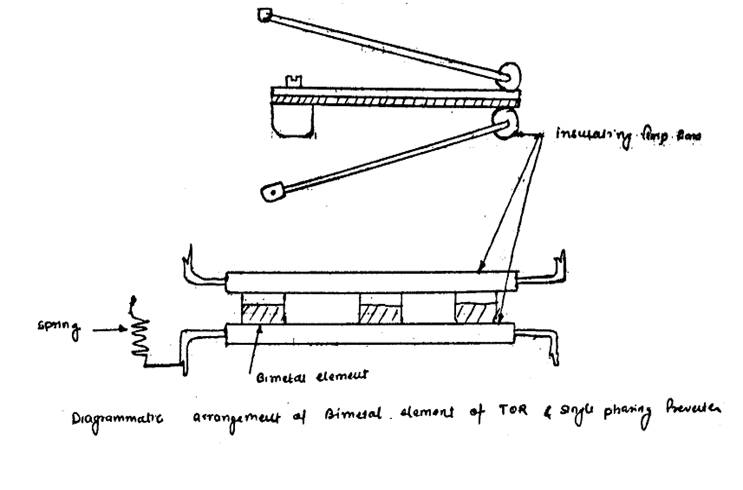

3 bimetal thermal strips one in each phase, the

ends of which projects between 2 parallel guides one fixed and the other

movable and spring controlled. All 3 strips can respond in unision

to balanced 3phase overload but one or two of the strip will act independently

in event of single phasing. This action is accentuated by open circuited phase

and cooling of and thereby deflecting in opposite direction.