Question

With reference to the

condition monitoring, of electrical machinery:

(a) State TWO important parameters that may be

recorded;

(b) Explain how the

parameters are measured and what defects may be revealed.

Answer.

Condition Monitoring (another form of preventive maintenance) is that

in which equipment is regularly monitored and tested.

When monitoring indicates

that breakdown is imminent, the equipment is repaired or replaced and any other

specified maintenance procedures carried out

Regular insulation testing

and vibration testing are two forms of condition monitoring.

Insulation resistance – all

electric equipment has insulation. The purpose is to keep electric current in

the conductor and to prevent contact with live wires. The electrical resistance

of insulation must be very high [mΩ] to prevent

current leaking away from conductor. Insulation resistance is measured between

Conductor and earth,

Conductors.

The electrical insulation

of electrical machines and cables is regularly measured using a standard 'Megger' type insulation tester.

Vibration

measurement

All machinery installations

have characteristic vibrations when in operation. Recordings of these vibration

characteristics, taken when the machinery is in good condition and operating

satisfactorily, provide a standard against which to judge the future condition

of the machinery, to diagnose faults and to decide on the maintenance required.

Measurement of insulation resistance.

Preparing for the actual test.

Correctly preparing the

equipment and insulation tester is crucial to your safety and the well being of

your wiring and machinery. Adhere to the following four-step process before

every test:

Take the

equipment out of service.

Shut down the apparatus,

open all switches, and de-energize the unit. Disconnect the equipment under

test from all other equipment and circuits, including neutral and protective

ground connections. Make sure you follow proper lock-out/tag-out procedures

during this step.

Check what will

be included in the test.

The more equipment included

in a test, the lower the resistance reading. For this reason, it's very

important to inspect the installation and understand exactly what you're

including in the test. You don't want a true reading to be affected by

additional equipment. However, if a complete installation with several pieces

of equipment yields a high reading, it's safe to assume that each individual

apparatus will yield an even higher reading. Consequently, sometimes separating

components is unnecessary.

Discharge

capacitance.

It's important to discharge

capacitance before and after making an insulation resistance test. You should

discharge about four times as long as the test voltage was applied during the

test.

Check current

leakage at switches.

Make sure readings won't be

affected by leakage over and through switches, fuse boxes, or other

connections. Such leakage can be detected by watching the level of resistance

the moment the test leads are attached. Never perform an insulation test on an

energized line or apparatus.

Interpreting test results.

Interpreting test results.

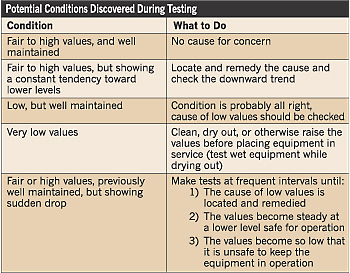

Deciding what to do with

the results of an insulation test can often be more complicated than actually

conducting the test itself. Every piece of equipment has a general insulation

“personality.” In other words, no two pieces of equipment may operate exactly

the same, but if a machine is behaving in accordance with its normal

tendencies, there's usually no cause for concern. However, a safe rule of thumb

is to judge results against a 1 megohm per 1,000V

ratio. Use the information shown in Table 2 on page 46 as a guideline for what

to do with the various conditions you may discover during your testing.

It's extremely important

that you consult the motor manufacturer's operating handbook for specific

information and guidance as to whether a particular value measured between two

points should be considered acceptable or questionable.

Insulation testing

manufacturers can provide test equipment capable of providing you with accurate

readings, but they have no way to determine if a particular measured value

indicates that a piece of equipment meets its specifications for insulation

integrity.

Continuity testing procedure.

Devices that can be used to

perform continuity tests include multimeter which

measure current

The following safety

precautions are the MINIMUM for using a multimeter.

· De-energize and discharge

the circuit completely before connecting or disconnecting a multimeter.

· Never apply power to the

circuit while measuring resistance with a multimeter.

· Connect the multimeter in series with the circuit for current measurements, and in parallel for voltage measurements.

· Be certain the multimeter is switched to ac before attempting to measure

ac circuits.

· Observe proper dc

polarity when measuring dc.

· When you are finished

with a multimeter, switch it to the OFF position, if

available. If there is no OFF position, switch the multimeter

to the highest ac voltage position.

· Always start with the highest

voltage or current range.

· Select a final range that

allows a reading near the middle of the scale.

· Adjust the "0

ohms" reading after changing resistance ranges and before making a

resistance measurement.

· Be certain to read ac

measurements on the ac scale of a multimeter.

· Observe the general

safety precautions for electrical and electronic devices.

In case of 3phase motor and

transformer all reading should be identical

If one reading is smaller

than the other this could indicate the possibility of short circuit turns in

that winding

Conversely a high

continuity resistance value indicates a high resistance fault or an open

circuit.