Question.

(a) With reference/to the insulation testing

of marine electrical plant:

State the reason for insulation

testing;

State the precautions to

be observed when testing intrinsically safe equipment

Type Ex. I'

Describe the overhaul of a a.c.\

Answer.

APART from the fact that good

insulation resistance is an essential condition for maintaining service, the

regular recording of insulation resistance values is undoubtedly the best

method of detecting deterioration and of indicating when remedial action is

desirable, or perhaps essential, in order to prevent complete failure.

Insulation resistance (IR) should

accordingly be measured and recorded at regular intervals, the recording being

preferably on a separate log-sheet for each important machine or circuit, so

that each fresh reading can be compared with previous values and any downward

trend immediately observed.

It cannot be too strongly emphasised that, subject of course to reasonable minimum

values being maintained, trends are more important than actual values; a single

value is of comparatively little significance.

The intelligent interpretation of

results is therefore of great importance and a general appreciation of the

factors involved is essential.

Precaution

Exi –

Equipment where circuit condition limits to < 30 V or B 50mA most commonly

used circuit are communication and alarm

Mostly they are used in pump room and

battery room

Here in addition to intrinsically

safe circuit an electric safe barrier is also fitted in the circuit

Purpose of such barrier is to limit

voltage and current in hazardous area when fault occurs in the circuit

All electrical equipment and

apparatus associated with intrinsically safe circuit needs periodic insulation

testing

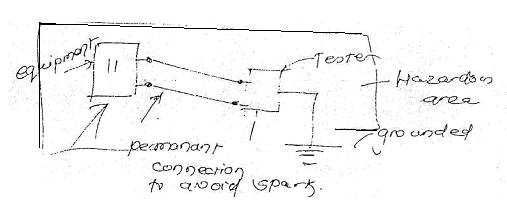

it is important that IR test are not

made in such a way that safety devices and insulation used in Exi apparatus and circuit are not damaged by excess test

volts [megger cannot be used it is 500V]

The energy output of intrinsically

safe equipment is very low

Intrinsically safe circuit has to be

tested for insulation by using insulation tester having drooping characteristic

to prevent high current

Tester should be intrinsically safe

when applied to circuit of small inductance and capacitance

Also when carrying out insulation

testing, test leads should be firmly connected to equipment through out and on

completion of testing they should not be detached

Until circuit has been discharged

through testing instrument

For this reason leave tester at least

for 1minutue after test has finished

Test carried out in hazardous zone

should not produce high voltage as it will damage equipment

If this has capacitor it has to be

discharged through equipment only

Therefore to be kept connected for

one minute after test has finished

Answer.

Overhaul of a.c.

motor [damped condition]

If a cage rotor motor has been

flooded with sea water, the insulation resistance can drop down to zero

MΩ. The main problem is to restore the insulation value of the stator

winding to a high value. This is achieved in three stages:

(i)

Cleaning

(ii) Drying

(iii) Re-varnishing

Salt contamination can be removed by

washing with clean, fresh water. Any grease or oil on the windings has to be

removed using a degreasant liquid such as Armaclean. Dry the stater

windings with low power electric heaters or lamps with plenty of ventilation to

allow the dampness to escape. Alternatively, the windings can be heated by

current injection from a welding set or from a special injection transformer.

Be sure to keep the injected current level well below the motor's full load

rating.

With the windings clean and dry, and

if the IR test remains high over a few hours, apply a couple of coats of good

quality air-drying insulating varnish.

Starter and other motor control gear

should be regularly inspected to check and maintain the following items:

a)Enclosure

- Check for accumulations of dirt and rust. Any corroded parts must be cleaned

and repainted. Examine the starter fixing bolts and its earth bonding connection

- particularly where high vibration is present, e.g. in the steering flat and

the foc'sle.

b)Contactors

and relays - Check for any signs of overheating and loose connections.

Remove any dust and grease from insulating components to prevent voltage

breakdown by surface tracking.

c)Contacts

- Examine for excessive pitting and roughness due to burning. Copper contacts

may be smoothed using a fine file and copper oxide, which acts as a high

resistance, can be removed using glass-paper. DO NOT file silver alloy contacts

or remove sliver oxide as it acts as a good conductor. A thin smear of

electrical contact lubrication helps to prolong the life of all contacts. When

contacts have to be replaced, always replace both fixed and moving contacts in

pairs.

Check contact spring pressure and

compare adjacent contact sets forequal pressure.

Check power and control fuse contacts for signs of overheating - lubricate

moving contacts on fuse-holder.

(d) Arc

chutes - Ensure that the magnet armature of contactors moves freely. Remove any

dirt or rust from magnet faces which may prevent correct closing.

(e) Connections - Examine all power

and control connections for tightness and signs of overheating. Check flexible

leads for fraying and brittleness.

(f)

Overcurrent relays - Check for proper size

(relate to motor full-load current). Inspect for dirt, grease and corrosion and

for freedom of movement. A thorough OCR per-

formance test can only be carried out by

calibrated current injection.

(g) Control operation — Watch the

sequence of operation during a normal start-up, control and shut-down of the

motor. Particularly look for excessive contact sparking. Remember to check

operation of emergency stop and auto restart functions

Overhaul of

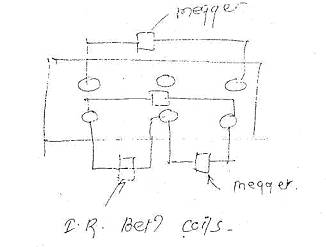

Check insulation resistance between

coil and earth and between winding

Make sure that connection are marked

[to avoid reverse rotation]

Main switch is put off take off fuse

Men at work board to be put up

Dismantle the motor

Rotor to be packed in plastic and to

be wiped out with cloth and kept in safe place

Considering S.W. has entered wash

stator winding with duistilled water

To wash thoroughly intricate places

use gun

Therefore most of the salts gets

dissolved and will come out

Put heating lamp to heat up the

winding

Check insulation resistance again

Check for any improvement

If no improvement then repeat process

till all salt is removed

Clean winding with electro cleaner

If insulation has improved and near

to 50 mohm spray the winding with quick drying

varnish

Assemble the motor

Check I.R. again between coil and

between winding W.R.T. body