Question

Describe a circuit breaker for a a.c.

generator using sketch to show how arcing is controlled

Explain the sequence of event that might occur if the breaker

opens on a short circuit and state the check you would require following such

event

Give a safe procedure to follow should a main circuit breaker

fails to open under fault condition.

Answer.

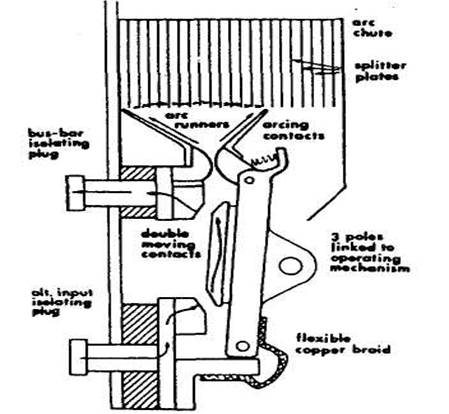

Sketch.

Alternator circuit

breakers

The air-break circuit breakers used for marine installations

are frame-mounted and arranged for isolation from busbar

and alternator input cable contacts by being moved horizontally forward to a

fixed position. The isolating plugs (Figure) are not designed for making or

breaking contact on load so the breaker must be open before the assembly is

withdrawn.

The alternator breaker for three-phase supply has a single

unit for each phase, of similar design to the example in Figure.

The three units are linked together by an insulated bar for

simultaneous operation.

Main fixed and moving contacts are constructed of

high-conductivity copper, and as an aid to low contact resistance the faces are

silver plated.

Main contacts are designed to carry normal full load current

without overheating and overload current until tripped, when a fault occurs.

Interruption of current flow results in the production of an

arc between contact faces.

Arcing is severe with overload current but is not a serious

problem during normal operation.

To prevent damage to main contacts, separate arcing contacts

are fitted which are designed to open after and close before main contacts.

These supplementary contacts are of arc-resisting alloy such

as silver tungsten and easily replaced if damaged.

The arcing contact shown has a spring which pushes it forward

to hold until after main contacts have opened.

Arc control requires that the arc be elongated and removed

from the gap between the arcing contacts. Electromagnetic forces associated

with the arc and thermal action cause it to move up

the arc runners to the arc chute provided for the purpose.

Thus the arc is elongated and finally chopped into sections

and cooled by the splitter plates.

Arc chutes are of insulating and arc-resisting material.

They confine the arc and produce a funnel effect which

assists thermal action.

Splitter plates are of metal (steel or copper) in some

breakers, and in others of insulator material.

Interruption of the arc is assisted by the current dropping

to zero during the cycle (however, with three-phases the zero points in each

phase are staggered).

Contact opening is therefore followed by a current zero and

this means that for the next part of the cycle, an arc has to be struck across

a gap.

Successful removal of ionised gas (from the arc which

resulted from contact opening) will increase resistance in the air gap between

contacts. When gas remains, it provides a path across which the arc can

re-strike.

The rate at which the gas is removed is such that the arc

will not re-strike more than two or three times.

Breaking speed is made as high as possible by powerful

throw-off springs and light construction of the moving arm assembly. Rebound at

the end of the opening movement is prevented by anti-bounce devices.

The alternator breaker has an over current trip but the major

consideration is that

The alternator breaker has an over current trip, but a major

consideration is that the supply of power to the switchboard must be maintained

if possible.

The breaker therefore is arranged to be tripped instantly

only in the event of high over current such as that associated with short

circuit.

When over current is not so high, a delay with inverse time

characteristic allows an interval before the breaker is opened. During this

time the overload may be cleared.

Straight overload (apart from the brief overload due to

starting of motors) is reduced by the preference trips which are designed to

shed non-essential switchboard load.

Preference trips are operated by relays set at about 110% of

normal full load.

They open the breakers feeding ventilation fans, air

conditioning equipment etc.

The non-essential items are disconnected at timed intervals,

so reducing alternator load.

A serious fault on the distribution side of the switchboard

should cause the appropriate supply breaker to open, or fuse to operate, due to

over current. Disconnection of faulty equipment will reduce alternator

overload.

After a short circuit trip the breaker should be

Inspected for possible damage to contacts

The close trip mechanism operated and checked

Insulation reading between poles and each pole to earth

should be taken

A minimum of 5 m-ohm is usually specified

by the manufactures

If the main circuit breaker fails under fault condition

Start another generator and take it on load

Shift maximum load on this generator

When the load on the faulty generator is very low then trip

the breaker manually