Tank liquid sensors are an

integral part of the ship

Describe with the aid of

suitable sketches the working principle of cap activity type level sensor

Ultra level sensor

Float.

Level Detection and Measurement by Using a

Float Sensor

Level Detection Using a Float Sensor

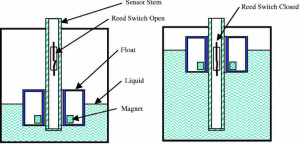

Principle of Operation: A liquid level control system by

using a float sensor works on the principle of buoyancy, which states, “A float

immersed in a liquid is buoyed towards upward direction by an applied equal

force to the weight of the displaced liquid”. As a result, the body drives

partially and gets submerged upon the liquid surface and covers the same

distance the liquid level moves.

Construction: A level measurement float system

consists of a float, a sensor stem, a magnet, a reed

switch and a weight suspended on the outside of the open tank. A scale is fixed

on the outside of the tank, and the contents of the tank’s level are indicated

by the position of the weight along the scale.

Working: Level detection of liquids is often

done with a float-type

liquid level switch. The float transfers on a mechanical arm or

sliding pole and activates a switch when the level moves towards upward

direction. Sometimes the float itself contains a small magnet that

varies the state of a switch when the liquid level gets moving up and moves

into the original position. This type of level sensor comes with many advantages

like it is very simple, highly accurate, and best suitable for various products.

The

Disadvantages of this sensor are that it requires various

mechanical equipment, especially the pressure vessels.

Primary Areas of Float Sensor

Application: In view of the requirements

pertaining to the increase in usage of sealed tanks, the current industrial

systems make use of this type of float method for precise reading and

accuracy, which is a good example of electronics and mechanical engineering,

making it the most accurate level-measuring system for various applications in

very large storage tanks.

2. Level Detection and Measurement by Using

Capacitance Sensor

Level Detection Using Capacitance

Sensor

Capacitance

level sensors are made available for wide range of solids, aqueous, organic

liquids and slurries. This technique is frequently stated as the

radio-frequency signals applied to a capacitance circuit. The capacitive

sensors are designed to sense material with dielectric constants as low as 1.1

for coke and fly ash, and as high as 88 for water or other liquids.

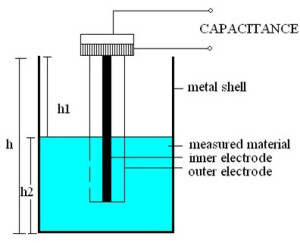

Principle of operation: The principle of capacitive level

measurement is based on the change of capacitance. There are two plates in

capacitive sensor: one plate acts as an insulated electrode and the other plate

acts as a tank wall. The capacitance depends on the liquid level. An empty tank

has low capacitance while a filled tank has higher capacitance. A simple

capacitor consists of two electrode plates separated by a small thickness of an

insulator such as solid, fluid, gas, or vacuum.

The Value of C

depends on dielectric constant used, area of the plate and also on the distance

between the plates.

C=E(KA/d) Where: C = Capacitance in Pico farads (pF) E = a constant known as the absolute permittivity of

free space K = Relative dielectric constant of the insulating material A = Effective

area of the conductors d = Distance between the conductors

This change in capacitance can be

measured by using an AC Bridge.

Construction and Working

The measurement

of liquid level is done by applying a Radio Frequency signal between the

conductive probe and the vessel wall. The Radio Frequency signal results

in a very-low current which flows through the dielectric process material in

the tank from the probe to the vessel wall. If the liquid level in the tank

drops, then the dielectric constant decreases, which leads to the drop in

capacitance reading as well as minute drop in current flow.

This change can

be detected by the liquid-level switch’s internal circuitry and translated into

relay state changes of the level switch in case of a point level detection.

The main

advantages of these capacitance systems include easy installation, broad

application range, good accuracy suitable for variety of applications and

highly recognized and well -proven technology.

The

disadvantages include sensitivity to changes in the measurable properties such

as dielectric constant and conductivity which creates an issue; furthermore, it

is an intrusive system.

Primary

Areas of Capacitance Sensor Application: Capacitance level sensor probes are

used for measuring the levels of:

- Fluids

- Liquid metals

at very-high temperature range

- Dissolved

gases at very-low level of temperature

- Very-high

density industrial processes.

Continuous Level Measurement and Detection

Systems

A continuous

level sensor is most sophisticated and also provides liquid level monitoring of

an entire system. This liquid level sensor is used to measure the fluid level

within a specified range, moderately than at a one point, which produces an

analog output and directly correlates to the level in the vessel. To create a

liquid level management system, the output signal is interconnected to process

a control loop and linked as a visual liquid level indicator. This measurement

system consists of variety of sensors such as

- Ultrasonic

Sensor

1. Level Detection and Measurement by Using

Ultrasonic Sensor

Level Detection Using Ultrasonic

Sensor

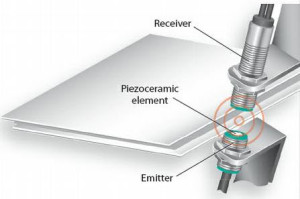

Ultrasonic level

instruments works on the basic time-of-flight principle which states that

sending a sound wave from a peizo electric transducer

to the contents of the vessel, which may contain liquid, solid or slurries

level.

This liquid

level sensor comprises two elements such as an associated electronic

transceiver and a transducer with relatively high efficiency. In case of a liquid level controller, the fluid

level can be determined by measuring the trip time difference between a

transmitted ultrasonic pulse and a reflected echo.

The frequency

range for ultrasonic methods varies from a range of 15-200 kHz for transmitting

and receiving ultrasonic waves. The lower frequency instruments are used for

the measurement of difficult applications such as longer distances and

solid-level measurements, and the instruments with higher frequency are used

for shorter liquid level measurements.

The ultrasonic

sensors are advantageous as they are not in direct contact with the product,

and the level measurement is done without involving any physical contact. They

do not have any moving parts.

As a

disadvantage, these types of sensors are not suitable for higher pressures in a

vacuum and temperature limits of up to 170 degree centigrade.