What is soft starting

of an induction motor

Describe with a

circuit using thyristor used for soft starting

Discuss its

advantages and disadvantages.

A soft starter is

another form of reduced voltage starter for A.C. induction motors. The soft

starter is similar to a primary resistance or primary reactance starter in that

it is in series with the supply to the motor. (Three wire or standard

connection) The current into the starter equals the current out. The soft

starter employs solid state devices to control the current flow and therefore

the voltage applied to the motor. In theory, soft starters can be connected in

series with the line voltage applied to the motor, or can be connected inside

the delta loop of a delta connected motor, controlling the voltage applied to

each winding. (Six wire or Inside Delta connection)

Soft starters use a

combination of power electronics and electronic control circuitry to slow

increase the voltage on the motor during starting; ensuing a smooth

acceleration.

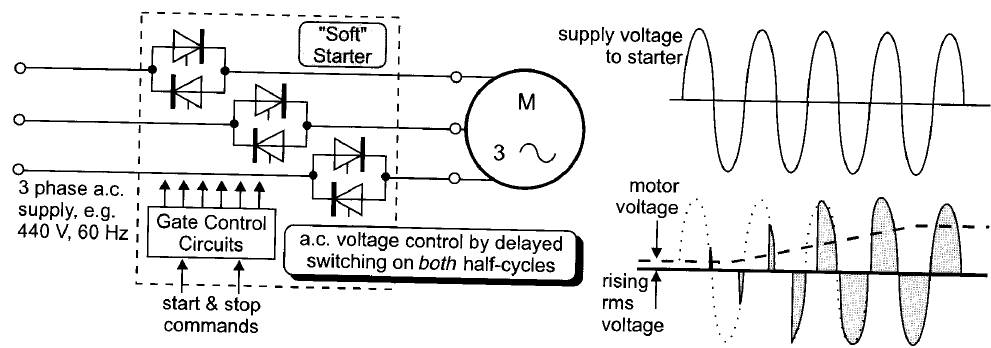

This method† of supplying a gradually increasing a.c.

voltage during start-up generally refers to an efficient electronic

switching† technique

A† basic†

method† shown†† in†

Fig is to† use† back-to-back†

connected†† thyristors or† triacs in†

the† supply† lines†

which† are "gated" to† delay "turn-on" within† each a.c. †half-cycle.†

This† delayed†† switching applies†† a†

reduced† average†† a.c.†

voltage to the† motor.

The applied† motor†

voltage is gradually ramped up by the†

starter software program until the full voltage level is reached. To

achieve maximum† efficiency, the† electronic†

switching circuit† can† now be bypassed† for normal†

running.

Soft starters use

thyristors (Silicon Controlled Rectifier) to control the energy delivered to

the motor. A thyristor is a device which turns on when a pulse is applied

to its gate and will continue to conduct until the current drops to zero (at

which time it turns off). In an AC sine wave current goes to zero

each half cycle, allowing the current to be turned off and making it possible

to use use thyristors to implement soft starting.

Voltage Control by Thyristor Firing

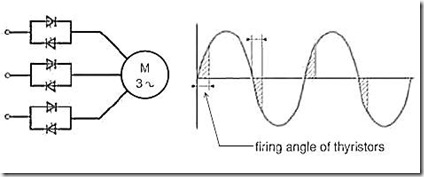

If the thyristors are

turned on at the start of each half cycle, the full voltage is applied to the

motor. If the thyristors are never turned on , then no voltage is

applied. If the thyristors are turned on part way through the half cycle

only a proportion of the voltage will be applied to the motor. By

controlling the turning on (firing angle) of the thyristors the amount of

voltage on the motor can be controlled. Starting with a large firing

delay, this is gradually reduced and the voltage on the motor will ramp-up

during starting.

In addition to

starting, soft start units can also be used for stopping the motor, by ramping

the voltage down. This is particularly useful where sudden loss of

driving torque would create mechanical shock on the load.

Electronic soft

starters contain the thyristors (power side) and necessary electronics to

control the firing (via user settings). Modern soft starters have a host

of features; the most common being options to set varying start and stop ramps,

setting of the initial starting voltage, current limiting control and thermal

overload protection.

The easiest

application of electronic soft starters is one unit per motor. To reduce

cost, sometimes more than one motor is connected in parallel to a soft starter,

or motors are started in sequence by switching the soft start unit between

motors. While these methods can be used, care has to be taken to ensure

that the units are adequately rated for the required duties.

As a cautionary note,

firing of thyristors other than a zero voltage (current) will create a

non-linear load characteristic, generating transients and

harmonics. In general application (and given that the

transients/harmonics are only present during starting) these are not a

problem. However, there could be instances and special situations where

these do have an adverse effect on the power system.

Power and Control

Circuiting

Power Circuit

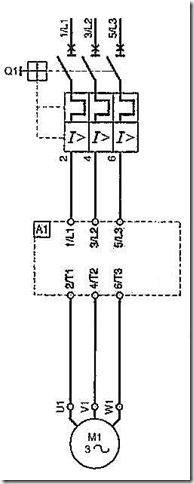

The figure

illustrates possibly the simplest connection of an electronic soft

starter. In this the unit is simply connected into the circuit and

carries out the necessary functions.

While this is the simplest

implementations, you will often find a bypass contactor (to switch-out the

thyristors when the motor is up to speed) and a line contactor to switch the

circuit in/out. Other variations of control circuit would include

cascading start and control for both forward and reverse directions.

Invariably there would also be communications to either control or monitor the

functioning of the motor.

Features and

Application

Soft starters have

many features not found in traditional starting methods and which can be of

benefit in some situations. These include:

Adaptive Acceleration

Control - soft starter learns motorís performance during start and stop,

then adjusts control to optimize performance

Soft Stopping -

slowly bring the motor to a stop

DC Braking -

injecting DC to reduce motor stopping time

Soft Braking -

changing contactors on starter input, reversing motor direction and applying

braking

Current Limiting -

limit starting current to a pre-defined value (may lower torque to much and

motor may not accelerate)

Current Ramping -

increasing the current over a given time to a specified limit

Jog - allows the

motors to be run at reduced speed for some time

Kick Starting -

using a brief high bust of current at the motor start to get it going, then

reducing the current

Thermal Modeling -

motors the motors thermal characteristic, allow performance optimization

Communication - most industrial protocols will be supported, enabling enhanced

control/monitoring

Line contactors can

be used (but not strictly necessary) to isolate the soft start when not in use

(should be rated AC3). If required, by-pass contactors can by used to minimize

heat build up due the to SCR's (can rated AC1 as they do not carry starting

currents).

Sequence starting -

can be used to start several motors in sequence (or parallel). Starters needs

to be rated for full start duty. Additional wiring, contactors and control

relays may not make this an economic option.

Power factor correction if required should only be installed on the line side

and switched in when the motor is at full speed (AC6 contactors). Capacitors

installed on the motor side can cause resonance, increased voltages and

equipment failure.

Inside delta

connection is a technique which can be used with six winding motors. In this

configuration, only have the delta is completed in that starter, thus reducing

the current the starter is required to carry. On some soft starters are able to

be used in this type of application.

Characteristics:

Available starting

current: 25 to 75%, adjustable

Peak starting

current: 2 to 5 In, adjustable

Peak starting

torque: 10 to 70%, adjustable

Advantages:

Soft start enhances

motor start performance in many ways including:

††††††††† †➜ Smooth acceleration without

the torque transients associated with electro-mechanical

†† reduced voltage starters.

††††††††† †➜ Voltage or current is

applied gradually, without the voltage and current transients

†† associated with electro-mechanical reduced

voltage starters.

††††††††† †➜ Lower start currents and/or

shorter start times because constant current control gives

†† higher torque as motor speed increases.

††††††††† †➜ Easy adjustment of start

performance to suit the specific motor and load.

††††††††† †➜ Precise control over the current

limit.

††††††††† †➜ Consistent performance even

with frequent starts.

††††††††† †➜ Reliable performance even

if load characteristics vary between starts (eg loaded or

†† unloaded starts).

In addition to

superior starting performance, soft starters also provide a range of features

not

available from other

reduced voltage starters. This includes areas such as:

††††††††† †➜ Soft stop (which helps

eliminate water hammer) ➜ Metering and monitoring

††††††††† †➜ Braking ➜

Operating history and event logs

††††††††† †➜ Motor and system protection

➜

Communication network integration

Disadvantages:

More Expensive

Can Inject Transients

into Supply