Compare methods of obtaining speed regulation of 3 phase

induction motors generally used in tankers by means of rotor resistance.

Cascade system. Pole changing. Give examples where each system may be employed

with advantages.

The speed of an

induction motor is given as N = 120f/p (1-S). So obviously the speed

of an induction motor can be controlled by varying any of three factors namely

supply frequency f, number of pole P or slip S.

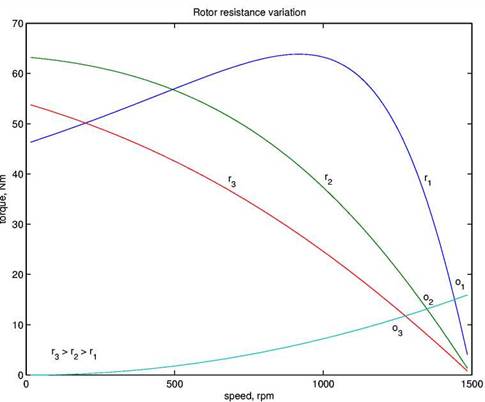

Rotor Resistance Control.

This method of speed

control has characteristics similar to those of dc shunt motors controlled by

means of resistances in series with the armature.

This method is

applicable for slip ring motors.

It is same as that of

armature control method for dc series motor.

A star connected, 3

phase rheostat is joined in series with the rotor circuit via slip rings.

Here slip rings are

not short circuited as they are when rheostat is only used for starting of

a induction motor.

Slip for a given

torque can be varied by varying the rotor resistance.

But the main

disadvantage of this method is I^2.R (Cu) losses are also increased with

increase in rotor resistance.

Because of these

increased losses this method is used where speed control is required for a

short time.

Its drawbacks are lower

efficiency and poor speed regulation due to increase in motor resistance.

Because of

convenience and simplicity, it is often employed when speed is to be reduced

for a short period only.

Figure Speed-torque

curves : rotor resistance variation

Speed Control by Cascade Arrangement.

In this method, two

motors are required, at least one of which must have a wound rotor. The

two motors may be mechanically coupled together to drive a common load. In

practice, it is customary, to connect the rotor output of first machine to the

stator of second machine in such a way that the revolving field of both the

machines are in the same direction; under this condition the resulting

synchronous speed will be given as

Ns = 120f/P1 +P2

Where f is supply

frequency and P1 and P2 are the number of poles on machines

I and II respectively.

Further speed

control, if required, can be obtained by having second machine also of wound

rotor type and inserting control resistance in the rotor circuit of the second

machine.

By changing of Number of Poles.

This method is

generally not applied to slip-ring motors as in such machines this method would

involve considerable complications of design and switching, since the inter-connections

of both primary and secondary would have to be changed simultaneously in a

manner to produce the same number of poles in both windings. With two

independent sets of stator windings, each arranged for pole changing, as many

as four synchronous speeds can be obtained in a squirrel cage motor. This

method has the advantages of simplicity, good speed regulation for each

setting, high efficiency, and moderate first cost and maintenance. This

method is very satisfactory for applications such as ventilating fans,

conveyors, machine tools, or other applications which require operation at only

two or four speeds.