Question

What is intrinsic electric safety?

Can live maintenance be done

on intrinsically safe circuit?

Describe intrinsically safe

equipment used on board ship.

Intrinsic safety (IS) is a

protection technique for safe operation of electronic equipment in explosive

atmospheres and under irregular operating conditions. The concept was developed

for safe operation of process control instrumentation in hazardous areas. As a

discipline, it is an application of inherent safety in instrumentation.

The theory behind intrinsic safety

is to ensure that the available electrical and thermal energy in the system is

always low enough that ignition of the hazardous atmosphere cannot occur. This

is achieved by ensuring that only low voltages and currents enter the hazardous

area, and that all electric supply and signal wires are protected by zener safety barriers. Sometimes an alternative type of

barrier known as a galvanic isolation barrier may be used.

In normal uses, electrical

equipment often creates internal tiny sparks in switches, motor brushes,

connectors, and in other places. Such sparks can ignite flammable substances

present in air. A device termed intrinsically safe is designed to not contain

any components that produce sparks or which can hold enough energy to produce a

spark of sufficient energy to cause an ignition. For example, during marine

transfer operations when flammable products are transferred between the marine

terminal and tanker ships or barges, two-way radio communication needs to be

constantly maintained in case the transfer needs to stop for unforeseen reasons

such as a spill. The United States Coast Guard requires that the two way radio

must be certified as intrinsically safe.

Another aspect of intrinsic safety

is controlling abnormal small component temperatures. Under certain fault

conditions (such as an internal short inside a semiconductor device), the

temperature of a component case can rise to a much higher level than in normal

use. Safeguards, such as current limiting by resistors and fuses, must be

employed to ensure that in no circumstance can a component reach a temperature

that could cause autoignition of a combustible

atmosphere.

No single field device or wiring is

intrinsically safe by itself (except for properly designed battery-operated,

self contained devices), but is intrinsically safe only when employed in a

properly designed IS system. Such systems are usually provided with detailed

instructions to ensure safe use.

An intrinsically safe circuit is one that is

designed for a power so low that any spark or thermal effect produced by it,

whether there is a fault or not, is incapable of igniting the surrounding

flammable gas or vapour. It follows that

intrinsically safe equipment is used in such circuits and is designed on the same

basis, i.e. of being unable to produce a spark with enough power to ignite the

specific flammable vapour or gas involved. Intrinsic

safety technique

requires not only that a system is designed for operation with very low power, but also that it is

made invulnerable to high external energies and other effects.

If a fault can adversely affect the

safety of the equipment it is called a ‘countable’ fault. The situation is

further complicated because the apparatus standard permits some specially

designed components to be regarded as infallible and some inadequately designed

features to be failed in normal operation. Consequently there are faults that

are not considered to happen, faults, which are counted, and faults, which are

imposed but not counted.

One of the major advantages of

intrinsic safety is that ‘live maintenance’ on equipment is permitted without

the necessity of obtaining ‘gas clearance’ certificates. A consequence of this

is that during the safety analysis the possibility of open circuiting and

short-circuiting any field wiring is regarded as normal operation. Fortunately

understanding the apparatus standard and faults is only necessary for apparatus

designers and certifying authorities. The apparatus certificates remove the

necessity to consider faults, except for field wiring faults, in system design.

The ability to do live maintenance

on an intrinsically safe system is a major benefit of the technique. It is

difficult to test an instrument system with the power removed, and difficult to

obtain a meaningful ‘gas clearance certificate’ that covers the whole of the

area affected by a system. Consequently live working is very desirable. There

are however factors, other than gas ignition, that have to be considered

whenever an instrument system is taken out of commission and consequently local

safety practices such as ‘permits to work’ have still to be observed.

Permitted practices on the plant

The design of intrinsically safe

apparatus and systems ensures that the short circuit and open circuit of field

wiring cannot cause ignition of a gas atmosphere. The concept of live

maintenance uses this feature but does not extend to carrying out detailed

repairs; for example, repairing printed circuit boards within the hazardous

areas. In practice, the permissible actions are restricted by the available

tools hence deciding what is permissible is not difficult. IEC 60079-17

restricts live ‘working’ to:

i) Disconnection

of, and removal or replacement of electrical apparatus and cabling

ii) Adjustment of any controls

which is necessary for the calibration of the electrical apparatus or system

iii) Removal and replacement of any

plug in components or assemblies

iv) Use of any

test instruments specified in the relevant documentation. Where test

instruments are not specified in the relevant documentation, only those

instruments, which do not affect the intrinsic safety of the circuit, may be

used

v) Any other maintenance activity

specifically permitted by the “relevant documentation”

These requirements are in line with

the normal practice of maintenance on field mounted equipment and hence create

no problem. Work on associated safe area apparatus, such as the intrinsically

safe interface is restricted in the same way, except that there is greater

freedom to operate on the safe area terminals.

Recently developed interfaces tend

to operate from 24V supplies and there is no risk of electrocution. However it

is not unusual for interfaces with relay outputs to be switching higher

voltages, which may create a significant shock risk. Where this risk occurs,

adequate warning labels are required and the relevant precautions should be

taken during the maintenance process. There is no risk of a significant

electric shock being received by a technician working on an intrinsically safe

circuit. There is a hypothetical possibility but in practice this is not a real

problem actions are permitted, they are frequently embodied in the apparatus

certificate and manufacturer’s instruction. This information should be made

available to the relevant technician on the work sheet, as he is not likely to

have ready access to the certificate and/or instructions. The apparatus marking

would carry the ubiquitous ‘X’ marking but this is almost universally applied

and consequently largely ignored.

Permitted practice in the workshop

The repair and testing of

intrinsically safe and associated apparatus should only be carried out in

favourable conditions and by adequately trained technicians. The IEC standard

IEC 60079-19 provides some guidance on the approach to repair of intrinsically

safe equipment. There are always practical and economic limitations on what is

practicable. For example, shunt diode safety barriers are invariably

encapsulated and not repairable. Isolating interfaces are usually in boxes that

are difficult to open, coated in varnish and impossible to test in detail

without specialist test equipment and knowledge of the circuit. In general

replacement by an identical unit is preferred for both economic and safety reasons.

Some repairs can be carried out without affecting the safety of equipment and,

usually, it is obvious what limitations apply. For example, damage to

enclosures does not usually directly affect the intrinsic safety of apparatus

and consequently a repair which restores the enclosure to its original level of

integrity (IP rating) is acceptable. The repair of printed circuit boards is

sometimes considered but is usually impracticable. Removing components without

damaging the board is difficult, repairing the coating on reassembly is messy

and maintaining the original creepage and clearance

distances may not be possible. A recent further complication is that if lead

free solder has been used, the use of solder containing lead usually results in

unsatisfactory joints. A record of any repairs should be maintained. The use of

before and after photographs (stored digitally) frequently simplifies the

process.

Intrinsically safe apparatus is currently made to

two standards of safety. Ex i(a) is the symbol for the higher standard, which requires that

safety is maintained with up to two faults. This type of equipment can be fitted in

any hazardous area. The other standard is given the symbol Ex i(b) and

apparatus made to this specification is safe with up to one fault. The Ex i(b)

products are not used in the most hazardous areas. Manufacturers of

intrinsically safe apparatus state that this method of protection is suitable

for electrical supplies

at less than 30 volts and 50 milliamps. It is used extensively for

instrumentation and

some control functions.

Care is exercised in design that capacitance and

inductance within the electrical installation are kept to a minimum, to prevent storage

of energy which in the event of a fault could generate an incendive

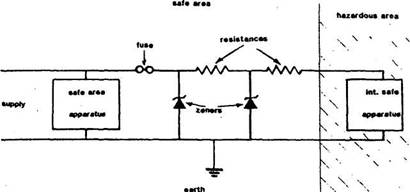

spark. Ex i systems are isolated from other electrical

supplies

even to the extent that the cables are not permitted to be in the same trays as

those of

other cables (to prevent induction effects). Systems are earthed and protection

is provided

by inclusion of shunt diode safety barriers between hazardous and non-hazardous areas

(Figure). The safety barriers have current-limiting resistors and voltage bypassing zener diodes to prevent excessive electrical energies from

reaching the hazardous

areas.

Neither certification nor marking is necessary

if none of the following values are exceeded in a device: 1.2 V,

Figure Safety barrier for Ex i equipment