Question

With reference to hull cathodic protection system of impressed current types

Sketch and describe such a system.

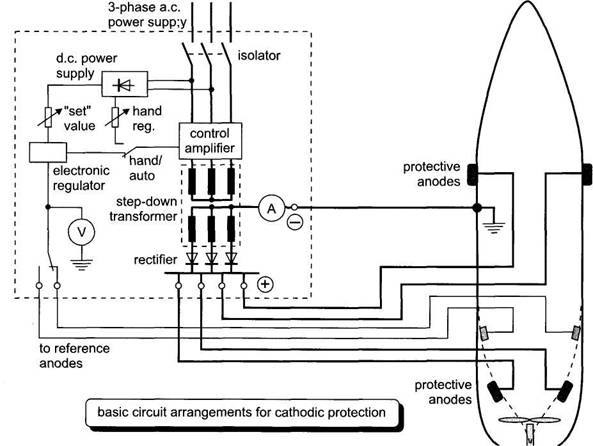

Cathodic protection

systems fitted in ships consist of a number of anodes (lead or platinised

titanium) fitted to the hull at selected places below the waterline, and control

equipment which automatically regulates the anode current to the required

value. Direct current is supplied to the anodes, after transformation and rectification,

from the ship's 440 V 60 Hz 3-phase a.c.

distribution system. The control equipment comprises reference electrodes,

an amplifier assembly and one or more transformer rectifier units.

The anode current control is

usually regulated by electronic thyristor controllers

and the diagram in Fig. outlines a typical scheme.

The control equipment automatically

monitors the size of anode current required which will vary with the ship's speed,

water temperature and salinity, condition of paint work etc. Typical anode current

densities range from 10 mA/m2 to 40 mA/m2 for the

protection of painted surfaces and 100 to 150 mA/m2 for bare steel surfaces.

The total impressed current for a

hull in good condition may be as low as 20 A. Maximum controller outputs may be

up to about 600 A at 8 V.

Explain how protection may be

ensured for the rudder and propeller.

To ensure that the rudder,

propeller screw and stabiliser fins receive the same degree of cathodic protection as the hull it is necessary to

electrically earth-bond these items to the hull. The rudder stock may be bonded

by a wire braid linking the top of the stock to the deck head directly above

it. Carbon brushes rubbing on the rotating main propulsion shaft effectively

bond the shaft to the hull. A periodic inspection of such earthing

is worthwhile as the brushes wear away and may occasionally stick in their

brush holders.

State any precaution that should be

taken when this type of system is installed.

Measurements should be regularly

logged together with the ship operating conditions, e.g.

location,

draught, water temperature, etc.

Changes in underwater hull area, speed, water temperature/ salinity and paint

condition will all cause the anode currents to vary. The hull potential should,

however, remain constant in a properly regulated system. Although the reference

electrodes and the monitoring facilities give a reasonable day to day check

they are only measuring in the vicinity of the fitted electrodes.

When the ship is moored singly or stopped

at sea, voltage readings can be taken between a portable

silver or zinc test electrode and the ship's hull. This portable electrode is

lowered 2-3 metres below the water surface and as close as possible to the hull

at specified positions around the ship.

Check the manufacturer's

instructions regarding the storage and setting up of the portable electrode.

Some have to be immersed in a plastic bucket of sea water for about 4 hours

before the hull test. With the cathodic protection switched

on and working normally, the voltage measured between hull and a silver/silver

chloride portable electrode should be 750-850 mV using a high resistance multimeter (e.g. analogue or digital type); the electrode

being positive with respect to hull.

When dry docked, ensure that the main

anodes and reference electrodes are covered with paper tape to prevent paint

contamination.