Question

With reference to fire detection

unit

Describe a rate of heat rise detector

with the aid of a sketch.

Describe the following methods of

checking the integrity of a suction of fire detection heads

Loop monitoring.

Line

termination monitoring.

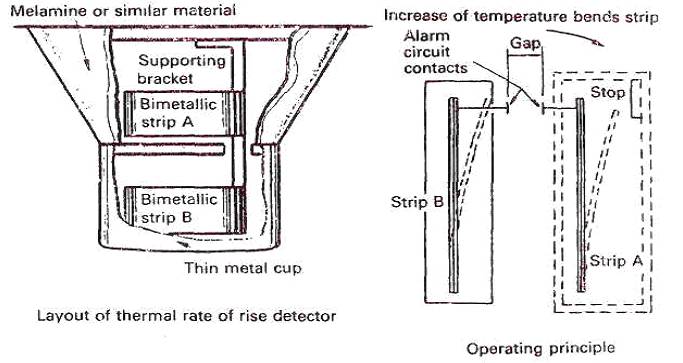

Bimetal strips made up from brass

and INVAR will deflect when heated due to the high expansion coefficient of the

brass and the low expansion coefficient of the INVAR, which is 36% nickel steel

Deflection increases with temperature and could in itself be used to complete

an electrical circuit and operate an alarm at some specific figure. However,

rate of rise can be detected using two bimetal strips (Figure) of different

thickness.

Figure

These are set up parallel to each

other and arranged to deflect in the same direction. Rapid temperature rise

will cause the thinner element to deflect more quickly than the other, so

causing contact to be made and the alarm circuit to be completed. A slow rise

causes a similar deflection in both elements, so that a gap between the

contacts persists, until a certain maximum temperature if reached when contact

is made because of other differences in the make up of the strips.

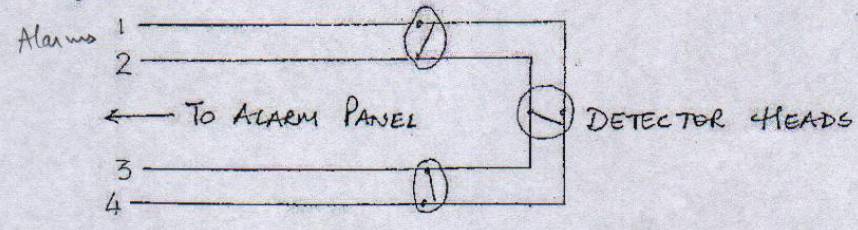

Loop monitoring.

The alarms are activated by the

closure of the contacts in the heads through 1 and 2

While continuity

is checked through 1 and 4 and 2 & 3.

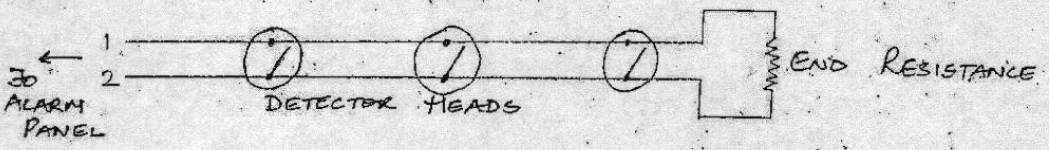

Line

termination monitoring.

The alarms operate when contact

across 1 & 2 close. Continuity is checked by monitoring the resistance at

the end of the line.

If the resistance of the line

measured across 1 and 2 is less than the end resistance the alarm sounds

If the resistance of the line

measured across 1 and 2 is greater than the end resistance plus the cable resistance

a system fault alarm is activated.