Question

Describe the requirement of each of

the following electrical equipment.

A shore to

ship supply of alternating current.

Portable lighting

for inspection of duct keel space.

.

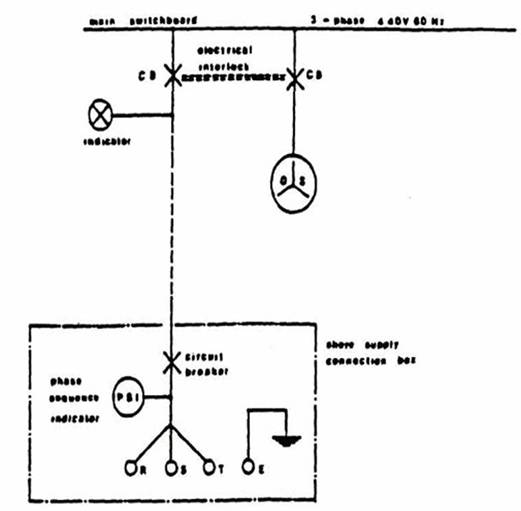

A shore-supply is required so that

the ship's generators and their prime-movers can be shut down for major

overhaul during a dry-docking period.

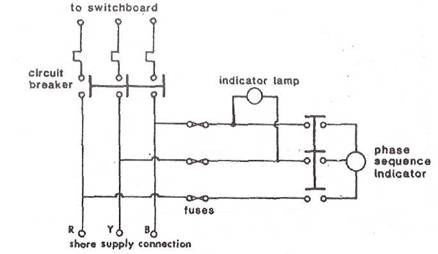

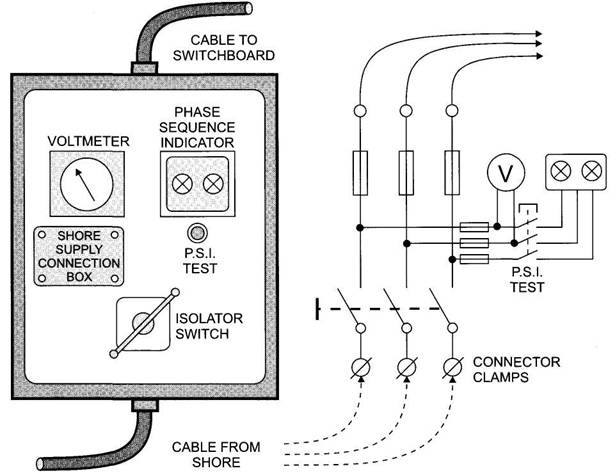

For an ac shore supply a phase

sequence indicator is fitted to indicate correct supply phase sequence. At the

main switchboard an indicator is provided, usually a lamp, to indicate that the

shore supply is available for connection to the bus bars via a connecting

switch or circuit-breaker. It is not normally possible to parallel the shore

supply with the ship’s generators. The ship’s generators must, therefore, be

disconnected before the shore supply can be conne3cted to the main switchboard

is interlocked with the generator circuit-breakers so that it cannot be closed

if the generators are still connected.

b) Faulty hand-held tools powered

by a.c. and having metal casings could impart a

lethal shock to the operator where the fault causes the casing to be live. The

hand(s) gripping the tool provide a large contact area (possibly damp with

perspiration) so that sufficient alternating current might flow to prevent

relaxation of the hold, and such a current could result in fatality. The risk

of shock is increased if the operator is working in damp conditions and

standing on metal plates or touching metal structure. There are similar risks

with various types of portable or semi-portable appliances - particularly lead

lamps.

The metal casings of portable

appliances are connected to earth through the earth wire in the three-core

cable and the earth pin in the plug, to give protection against a fault which could

make the casing live. Frequently, rough handling of portable equipment not only

causes the fault which makes the casing live, but also causes the earth wire to

be broken. Thus, when electrical connections and insulation are checked in the

course of regular inspection and cleaning, the earth core of the electric cable

should also be tested for continuity (i.e. with one terminal of the tester on

the metal casing of the appliance and the other on the earth pin of the plug).

Shock risk from portable tools is

greatly reduced if the power supply is taken from the secondary winding of a

transformer used to step down the mains supply to a suitable lower voltage,

with the mid-point of the secondary winding earthed.

If the secondary voltage is limited

to 110 V for operation of the single-phase appliance, then the potential shock voltage

between the casing and earth is limited to 55 V. (Secondary voltage can be made

lower if required.)

Double-pole switches are fitted to

control single-phase appliances fed in this way.

Flexible cable for portable tools

and equipment is reinforced and given extra protection by a rubber tube where

it enters the appliance.

Here and at the plug end the cable

is subject to bending and pulling: it can also be damaged along its length by

being pinched or cut by sharp edges and by touching a hot surface or lying in

oil, chemical or water. Sometimes the cable is cut by the tool being used.

Damage to the cable can cause shock

in a number of ways, or an earth or a short-circuit.