Question

Explain meaning with reference to

electrical safety equipment.

Intrinsically safe

An intrinsically safe circuit is

one that is designed for a power so low that any spark or thermal effect

produced by it, whether there is a fault or not, is incapable of igniting the

surrounding flammable gas or vapour. It follows that intrinsically safe

equipment is used in such circuits and is designed on the same basis, i.e. of

being unable to produce a spark with enough power to ignite the specific

flammable vapour or gas involved. Intrinsic safety technique requires not only

that a system is designed for operation with very low power, but also that it

is made invulnerable to high external energies and other effects.

Flame proof

Flameproof enclosures are used for equipment

where sparking or arcing occurs during normal operation, as in a switch or starter.

The spark is contained and likewise any flame or explosion (of gas which might enter

the casing), preventing ignition of a surrounding explosive atmosphere.

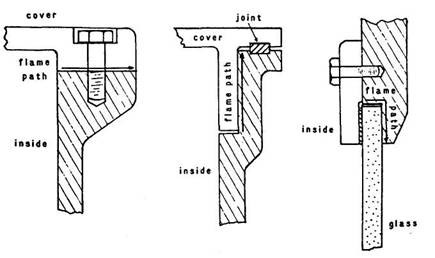

Figure Flame paths in Ex d equipment

Flameproof Ex d protection can be

applied to any type of rotating electrical machine but is intended for those

where the ignition of a flammable atmosphere is likely because sparks or arcing

occur during normal operation of the machine. Wound rotor induction motors with

slip-rings and brushes, also commutator motors, are,

because of sparking, likely to be protected by a flameproof (Ex d) enclosure.

With such protection, a particular piece of equipment may be acceptable for

zone 1 and zone 2 areas but the flameproof protection does not make it suitable

for the most hazardous zone 0 locations.

Increased

safety.

Increased safety (Ex e) equipment

A squirrel-cage induction motor is

a type of electrical apparatus which does not normally have any associated

arcing or sparking during operation and where running temperature is not

excessive. Such equipment can be made safe for operation in areas made

hazardous by the likelihood of flammable vapour, by the use of increased safety

techniques.

Insulation for windings and cables

is of high quality and protection is given against ingress of water or solids

which could cause insulation breakdown. Breakdown of insulation due to

overheating from overload is prevented by overload devices, which are an

essential part of the increased safety technique. Adequate clearance is given

to the fan and rotor to avoid mechanical sparks from rubbing contact and the

casing is made impact-resistant. Power supply terminals are of non-loosening

type and well separated to prevent tracking and the cables are firmly

supported. The overload devices which protect the insulation also prevent

excessive external or internal temperature.

Pressurised (Ex p) equipment

Some deck lights used for tankers

are operated by compressed air turbines which drive small individual generators

within the fitting to provide power for the lamp. The exhaust air pressurises

and purges the fitting, so excluding any flammable gas which might be present

in the external atmosphere. Failure of the air supply automatically causes the power

to be switched off.

The technique of pressurising is

also used in straightforward types of electrical apparatus, particularly where

it is necessary to install a non-standard piece of equipment in a hazardous

area. Ex p equipment is not permitted to be installed in very hazardous areas.

Alarms and automatic shutdown at loss of pressurisation are required if

normally sparking Ex p type apparatus is installed

where a flammable atmosphere is likely to occur.

Pressurisation has been used for

control cabinets and enclosed spaces for' safe containment of sparking

electrical equipment. All pressurised spaces must be thoroughly purged before

the equipment is switched on.

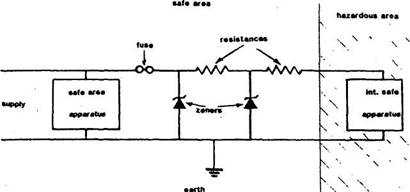

Sketch a safety barrier for intrinsically

safe circuit

Figure .4 Safety barrier

for Ex i equipment

The purpose of such a barrier is to

limit voltage and current in hazardous area when fault occurs.

Fuse to limit maximum current

through zener diodes.

Resistors

to limit maximum current in hazardous area.

Zenor diodes to limit maximum voltage

with hazardous areas.