Question

Sketch a diesel electric propulsion

arrangement for a ship

Describe the operation

Outlining how reversal of the

propulsion motor is achieved.

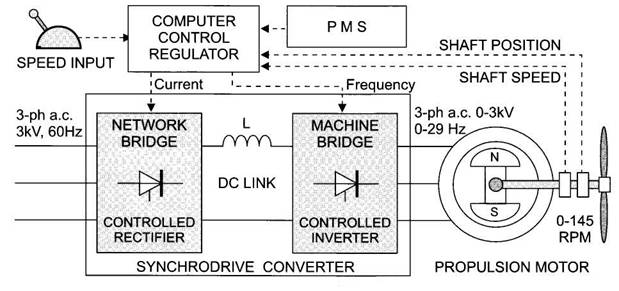

In a synchrodrive

system as shown in Fig., the computer receives a command (set speed) input and

many feedback signals (voltage, current, power, frequency etc.) but the obvious

regulating item is the actual shaft speed feedback forming a closed control

loop.

The principal parameters to be

controlled are the size of motor stator current (to set motor torque) and the

motor frequency to set the shaft speed.

In addition, the

In normal running and full-away

with both propulsion motor speeds within 5% of each other, the bridge can

select a shaft synchro-phasing mode which applies momentary

acceleration/deceleration to bring the propeller blades into an alignment

which minimises shaft vibration into the hull.

Speed and position are derived from

detectors on the non-drive end of the motor shaft.

At speeds of less than 10%, the

motor does not generate sufficient back e.m.f. to

cause automatic thyristor switch-off (line

commutation)

A thyristor

can only switch off when its current becomes zero.

This problem is overcome by pulse-mode

operation where the current is momentarily forced to zero by the thyristors in the controlled rectifier stage.

This allows the inverter thyristors

to turn-off so that the controller can regain control.

The decision is now which thyristor and which sequence of switching is required to

maintain the required shaft direction of rotation.

It is necessary to know exactly the

position of the rotor poles and this is provided by the shaft position encoder

for low-speed, pulse-mode operation.

When kicked above 10% speed, the

motor e.m.f. will be large enough to allow the

converter to revert to its normal line-commutation mode for synchronous operation

For normal running, above about 10%

speed, the operation is switched to synchronous mode where the thyristors in both bridges are switched off naturally (line

commutated) by their live a.c. voltages from supply

and motor

To reverse the shaft rotation the

forward/ ahead phase sequence of motor supply currents is reversed by the

inverter thyristors.

This reverses the direction of stator

flux rotation and hence shaft direction to astern.

The rate of deceleration to zero

speed must be carefully controlled before a shaft reversal to avoid large power

surges in the system.

For a motor braking operation, the inverter

bridge can be considered as a rectifier bridge when viewed from the live a.c. supply produced by the motor emf.

If the network (rectifier) bridge thyristors are switched with a delay angle greater than 90°

the d.c. link voltage reverses causing power flow

from the motor back to the supply (motor braking).

In this mode the roles of the

network and machine bridges are swapped over.