Question

Diesel electric propulsion, is now being chosen

as the power plant for an increasingly wide variety of vessels.

Sketch a simple layout of such an installation.

Explain the advantages of selecting such a plant.

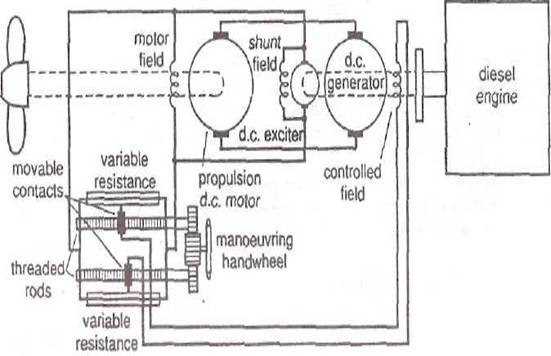

Simple

Ward-Leonard system for diesel-eieciric propulsion

The simple

Ward-Leonard arrangement for diesel electric propulsion (Figure.) is an all-d.c. scheme with a diesel engine as the prime mover driving

the single

An exciter

mounted on an extension of the generator shaft provides field current both for

the generator and for the direct current propulsion motor.

The exciter

is itself a

At

start-up, the armature windings of the exciter have current generated in them

when they pass through the field emanating from the residual magnetism of the

exciter poles.

The small

current generated initially, circulates through the windings of the exciter

poles, strengthening their magnetic fields until full output is reached.

The current

generated in the

It is

available to the field poles of the generator, but only through the regulating

resistances of the manoeuvring control.

If the

control contacts are at the raid positions of the resistances, then no current

flows to the main generator poles and there is no output from it to the

propulsion motor.

Rotation of

the manoeuvring handwheel and gears turns the

threaded bars to move the contacts along the resistances, in opposite directions.

As the

contacts travel toward the extremities and resistance lessens, current from the

exciter flows to the generator field poles.

The

direction of current flow and the level are used to control the output of the

generator and, in turn, the propulsion motor. Propeller speed is proportional

to the actual voltage produced in the generator and fed to the propulsion

motor.

The

advantages claimed for electrical transmission for main propulsion are :—

Reliability

in so far as a number of small generating sets can be used, should one or

more of the sets require attention or should break down take place, the ship

could still be run at slightly reduced speed until repairs were effected.

Economy.

The whole

power can be transmitted through one propeller running at its most economical

revolutions reducing the losses due to cavitation

also losses due to friction of extra bossing and brackets where multiple screws

are fitted.

The

electrical transmission is as efficient at half-load as at full load, as the

main generator prime movers are running at a constant speed and do not need to

be reversed when ship has to go astern.

A uniform

torque is maintained at all loads, thus eliminating the variable twisting

stresses obtained in reciprocating direct coupled prime movers.

Intermediate

shafting can be dispensed with as the motor on propeller shaft can be placed

well aft and the current led to it, thus allowing more room for cargo.

The

generating sets can be placed in any convenient position in the ship and not

especially in line with the propeller shafting. The same power is available for

going astern as for going ahead.

No reverse

turbine required.

Ease

of Control.

Manoeuvring

is very much simplified as shopping, reversing or slowing down can be done by

one switch.

Low

noise.

An electric

motor is able to provide a drive with very low vibration characteristic and

this is of importance in ocengraphic survey vessel

and cruise ships where for different reasons a low noise signature is

required.

Auxiliary

Power.

Since the

main generating sets can be made small, all or any may be used in port for

lighting, working winches, or cooling chambers.