Question

Describe the characteristics of a DC motor

Explain the advantages of such a DC motor for deck

machinery

Describe with the aid of a sketch a control system for

the motor in a

The characteristics of

Shunt or lightly compounded motors are suitable for

fans, pumps, etc., and variable speed is obtained economically, i.e. without

loss of overall efficiency, by shunt regulation.

Up to four-to-one speed variation is obtainable but

three-to-one is the more usual limit.

Where a wider range is essential it can be obtained by

a series resistance in the armature circuit.

For very low creeping speeds a series resistance and a

diverter resistance across the armature may be used.

When a wide range of speed is obtained by shunt

regulation it is necessary to ensure that the motor is not started with a

weakened field.

This would reduce the starting torque and cause

sparking at the commutator.

The regulator must be interlocked with the starter so

that it must be returned to the full field position before starting.

Series wound motors are used where a high starting

torque is required, such as for engine-turning gear, winches, windlasses and

capstans, boat winches, etc. The speed varies with the load and such motors

should never be run without load as the speed becomes excessive.

Sometimes a light shunt field is incorporated in order

to limit the light running speed.

Winches and capstans incorporate special control

equipment for dealing with the wide range of load and speed which-is necessary

for successful operation.

Ward Leonard systems are sometimes employed when a

wide speed range is required such as for winches.

In this system the motor is separately excited and the

armature is connected to a generator, the voltage of which can be varied.

The control is therefore on the shunt winding of the

generator and as the field currents are comparatively small the control gear is

correspondingly small. This system also has the advantage that very fine speed

control is obtainable from zero to full speed.

Motor Characteristics

The characteristic curves of a motor are those curves which show relation between the

following quantities :

(1) Torque and

armature current i.e. Ta/Ia characteristic. It is also known as electrical

characteristic.

(2) Speed and

armature current i.e. N/Ia characteristic.

(3) Speed and

torque i.e. N/Ta characteristic. It is also known

as mechanical characteristic.

This can be found from (1) and (2) above.

COMPARISON OF DC MOTOR CHARACTERISTICS

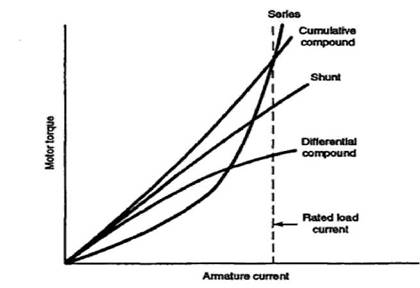

The characteristics of dc motors should be considered

when selecting motors for particular applications. Figures 8-11 and 8-12 show

comparative graphs that illustrate the relative torque and speed characteristics

of dc motors,

Torque relationships. A comparative set of

torque versus armature current curves for dc motors is shown in Figure 8-11, The effect of increased mechanical load on the shaft of

each type of motor can be predicted.

Figure 8-11 Torque versus armature current curves of

dc motors.

Series-wound dc motors have equal armature current,

field current, and load current (IA = lFI = II). The

magnetic flux (Φ) produced by the field windings is proportional to the

armature current (IA). The torque produced by a series-wound motor with low

values of IA is less than other motors due to lack of field flux development.

However, at rated full-load armature current the torque is greater than other

types of etc motors.

Shunt-wound dc motors have a fairly constant magnetic

field flux due to the high-resistant field circuit, an

almost linear torque versus armature current curve is a characteristic of

shunt-wound dc motors. Since torque is directly dependent on armature current,

as 1A increases, torque increases in direct proportion.

Compound-wound dc motors are of two general types:

cumulative and differential. Cumulative compound dc motors have series and

shunt field windings which aid each other in the production of an overall

magnetic field. In this type of motor circuit the general torque equation is: T

= K (Φs + Φp) IA,

where Φs is the series

field flux and ΦP is the parallel (shunt) field flux. The series field

flux increases as IA increases and the shunt field flux remains fairly constant

There fore, the torque curve (see Figure 8-1 1) for a cumulative compound dc

motor is always higher than that of a similar shunt-wound dc motor.

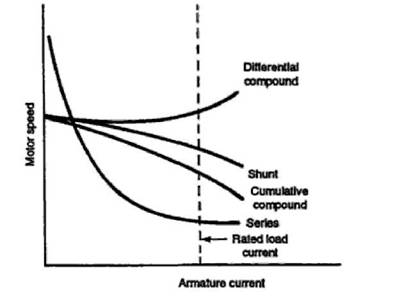

Figure 8-12 Speed versus armature current curves

of dcmotor

Advantages

Series motors are variable speed machine giving a low

speed on heavy loads.

They are ideal for traction, winch, hoist, and fan

Their excellent starting torque characteristic can be

used advantagesously where masses have to be accelertated quickly as for lifting or traction

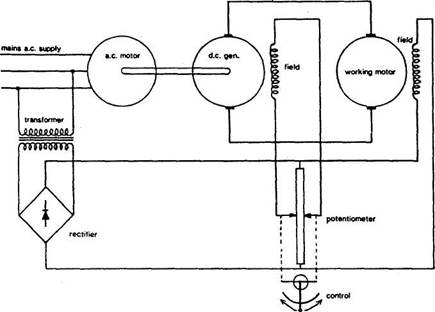

Control system for D.C. motor.

Ward-Leonard system.

This system, used for fine control of

The system was used for the motors of electric (as

opposed to hydraulic) steering gears of ships with

The working motor (Figure) which powers the steering

gear, windlass or other equipment is a d.c. machine,

because speed control of these is easy.

The method is to alter the voltage applied through the

brushes to the armature windings of the

The voltage is increased or decreased, not with the

use of resistances but by arranging an individual

Speed and

direction of the working motor vary with the magnitude and direction of applied

voltage.

Current for the windings of the field poles is derived

from the source of main power.

Where there is a.c. main power, current for the windings is transformed to lower

voltage and rectified.

The

Output of the generator is varied by changing the

current to its field windings through a variable control resistor

(potentiometer).

As magnetic field strength is altered by the change of

field current, so too is the generated voltage. Switch of direction of current

flow through the field poles, also with the potentiometer, will cause the

direction of the pole magnetic fields to change. This changes

the direction of generated current supplied to the motor and thereby also the

running direction of the motor.

The control lever can, by moving the potentiometer

contacts in opposite directions away from the mid-position shown in the sketch,

set the polarity and strength of the generator field poles.

By governing generator output to the armature of the

working motor, this in turn gives stepless speed

control of the working motor, in either direction.

The system as used for steering gear operation on