Question

It is proposed to operate a bow thrusters unit from a 3.3 KV

electrical supply outline suitable option for the design of installation under

each of the following heading.

Protection of main switch board

Overload of a bow thrusters motor

Cable protection.

MSB protection.

The HV side panel must be separate on or probably insulated

from adjacent IV panel.

It must have an independent earthing

system to hull

The HV bus bar should have harmonic filters connected to

avoid waveform distribution due to linear loads

MSB should be designed to withstand the rigours of sea life

i.e. it must withstand vibration, humidity, high temperature, sea water etc.

encountered in the ship.

The distribution system should have its neutral point earthed

via NER.

The circuit breaker [incoming and outgoing] usually are of

ACB type. This could be vacuum interrupter type or gas filled type.

Circuit breaker closing mechanism may be manual

[spring-loaded] or motor driven, stored charge spring type preferred.

Standard interlock and trips for manual trip, under voltage,

over current and short circuit trips must be incorporated.

Main monitoring instrument and lamps must be included e.g.

incoming voltage, frequency, current meter in/out power lamps, load status lamp

etc.

Additional safety features like anti condensation heaters.

Interlocks for main / emergency power, Interlocks for door closure are

preferred.

Motor overload protection.

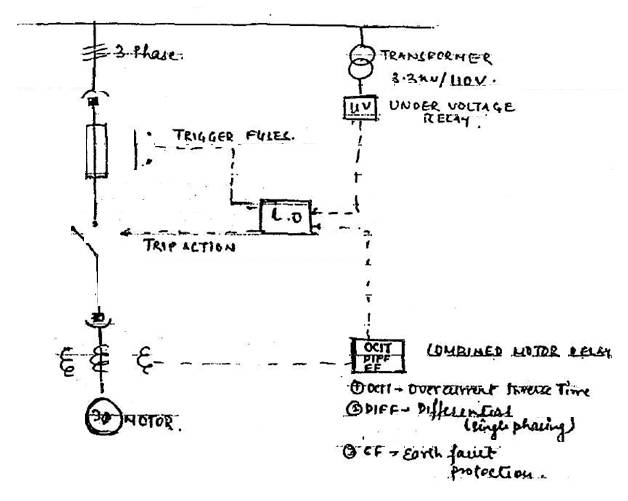

Usually HV motor have combined motor protection relay which

has overcorrect [inverse time delay]. A differential current and earth fault

monitor

This is connected to lock out relay to trip motor power in

the event of overload.

Beside this thermistor protection

is recommended for single phasing and high temperature trip.

Cable protection

Cable rating should be proper

Conductor should be rated for short circuit and maximum fault

current

Insulation material should be of higher quality preferred

EPR- ethylene propylene rubber.

XLPE cross linked polyethylene type.

Sheet material should be rated for short circuit, heat, oil,

chemical resistance, flame retardant type.

Cable installation standard like glanding,

junctions and cable tray routing to termination must be followed.