TROUBLE SHOOTING (BOWL

PERFORMANCE)

TROUBLE SHOOTING (BOWL

PERFORMANCE)

TROUBLE SHOOTING (BOWL

PERFORMANCE)

TROUBLE SHOOTING (BOWL

PERFORMANCE)

Troubles

The bowl does not close at

all.

Causes

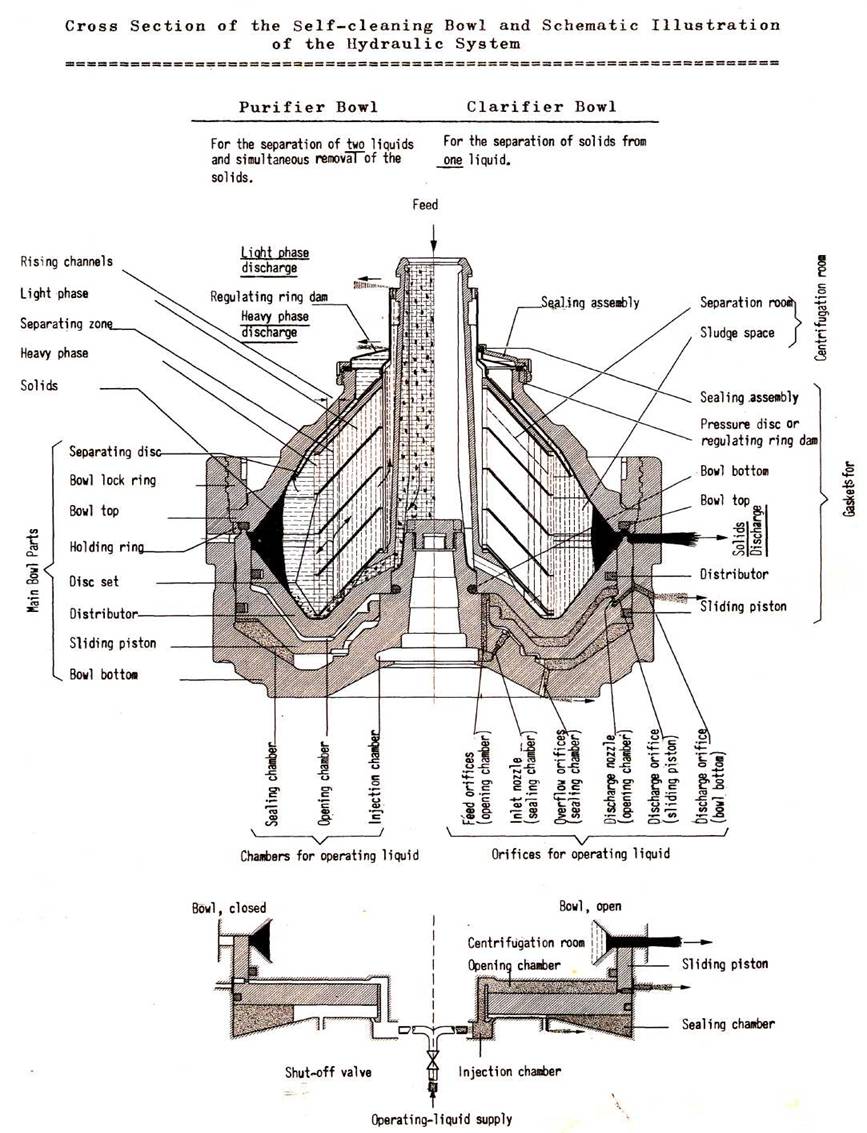

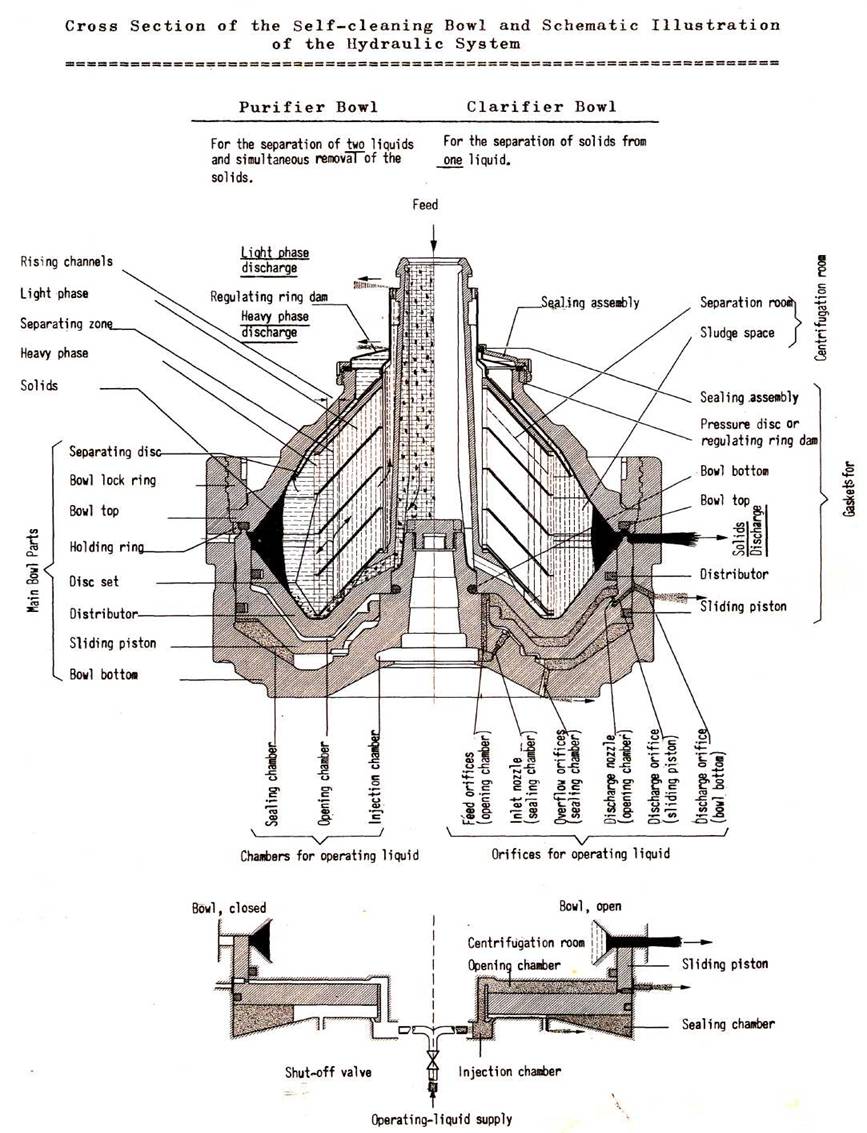

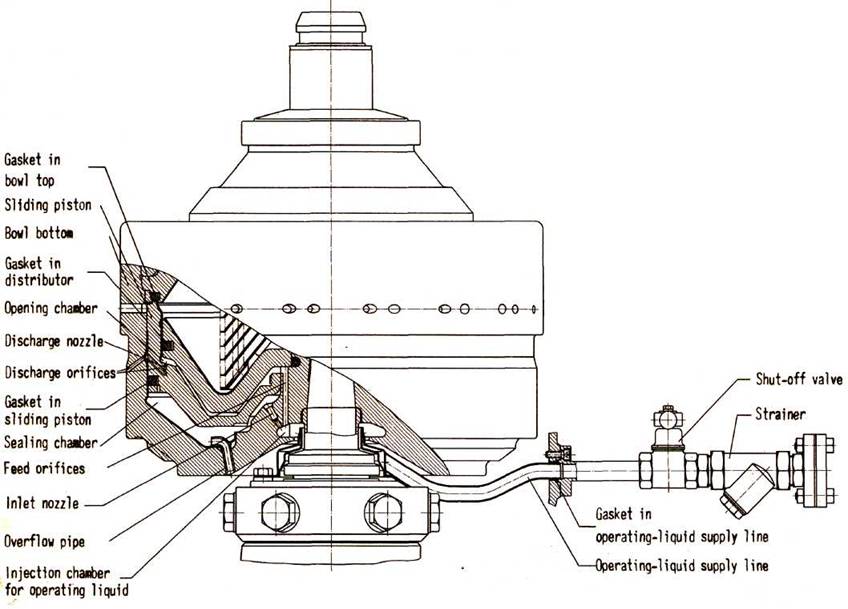

l) The orifice in bowl

bottom - between injection chamber and sealing chamber - is plugged or dirt

has collected in the injection chamber.

2) Orifice in sliding

piston,which discharges the water from the opening

chamber, is plugged.

3) Sludge has deposited at

the periphery of the opening chamber. This prevents the piston from rising to

its highest position.

4) Gasket in distributor or

sliding piston is damaged or its edges have been frayed through the up- and

down-movement of the sliding piston.

Remedies

Remove bowl bottom

Clean orifice and injection

chamber.

Remove sliding piston.

Clean orifice. Make sure not to enlarge diameter of orifice (1,2 mm).

Disassemble bowl and clean

opening chamber.

Replace damaged gasket. If,

however, only the edges of the gasket are frayed and the gasket is not damaged

otherwise, it can be re-used after grinding it off with an emery wheel.

Troubles

The bowl does not close

properly.

Causes

l) Gasket in distributor or

in sliding piston does not rest evenly on outer guide surfaces

2) Gasket in bowl top is

damaged.

3) Gasket has not been

installed into bowl bottom hub.

4) Gasket in distributor or

in sliding piston is uneven in height.

Remedies

If gasket fits too tightly,

stretch it.

Prior to inserting gasket,

grease groove in distributor or piston lightly.

Replace damaged gasket.

Install gasket.

Replace gasket.

Differences in height on a gasket must not exceed 0,25

mm.

|

Troubles |

Causes |

Remedies |

|

The bowl does not close

properly (cont'd.) |

5) Sealing edge of piston

is damaged. |

Re-turn sealing edge of

piston slightly or send piston to factory for repair. |

|

6) Shut-off valve for

operating-liquid does not close properly. |

Replace shut-off valve. |

|

|

7) Bowl is placed too

high; thus too small an amount of operating water gets into the injection

chamber. |

Adjust bowl to proper

height |

|

|

The bowl does not open at

all or not completely. |

l) The amount of operating

water available per unit of time is too .small |

Check water pressure. If

necessary, increase water pressure. |

|

2) Strainer in

operating-water line is dirty. |

Clean strainer. |

|

|

3) Gasket in

operating-water line is damaged. Part of the operating water gets lost. |

Replace gasket in

operating-water line. |

|

|

4) Operating-water line

has become narrowed as a result of dirt deposits. |

Clean operating-water

line or replace it. |

|

|

5) Dry sludge or rubber

scraps have become lodged between guide surfaces of distributor and sliding

piston or between sliding piston and bowl bottom. |

Clean bowl parts. Round

off edges of gaskets. Replace damaged gaskets. Apply thin film of molybdenum

disulfide paste to guide surfaces. |

|

|

6) Dirt has deposited in

sealing chamber. |

Clean sealing chamber. |

|

|

Incomplete de-sludging of

the bowl. |

l) Bowl has been closed

prematurely. Solid particles which could not be ejected have gradually accumulated

in the bowl and hardened through the long time of centrifugation. |

Clean the bowl. Leave operating-water

valve open for about 12 seconds. If necessary, carry out several flush

de-sludgings. |

|

Troubles |

Causes |

Remedies |

|

|

2) Orifice in sliding |

Reduce diameter of

orifice |

|

Incomplete de-sludging |

piston, which discharges |

to 1,2 mm. This is done by |

|

of the bowl. |

the opening water, has |

drilling up the orifice

to |

|

(cont'd.) |

enlarged. The sliding |

4 mm then closing it by |

|

|

piston moves downwards |

driving in a pin and re- |

|

|

too slowly. Part of the |

boring it to proper

diame- |

|

|

sludge remains in the |

ter; or reduce diameter

of |

|

|

bowl. |

orifice by beating. |

|

|

3) Tension of disc set |

|

|

|

has slackened. |

Check disc count; if |

|

|

|

necessary, add spare disc |

|

|

|

or blind spare disc. |

|

|

l) Bowl has been closed |

Leave operating-water

valve |

|

Gasket in bowl top |

prematurely. |

open for about 12 seconds. |

|

shows premature wear. |

Solids have become |

|

|

|

lodged between top of |

|

|

|

piston and gasket of |

|

|

|

bowl top. |

|

|

|

2) The feed liquid

contains |

Pre-strain feed liquid. |

|

|

abrasive solids. |

|

|

|

The amount of operating |

Instead of the manually |

|

The bowl opens after |

liquid in the sealing |

operated shut-off valve |

|

a long separating |

chamber has lessened dur- |

(for operating liquid) |

|

time. |

ing a long separating |

use a solenoid valve which |

|

|

time (due to evaporation |

is opened briefly at pre- |

|

|

etc.). |

set intervals by an

electron- |

|

|

|

ic timing relay . |

|

|

|

|

|

|

The bowl has not been |

Prior to removing

distributor |

|

The bowl does not |

cleaned properly prior |

and sliding piston,

dissolve |

|

close or open proper- |

to the long-term shut- |

the scale with citric

acid |

|

ly after a long-term |

down of the separator |

or formic acid. |

|

shut-down of the |

(see

sect. 9.6). Scale |

Then disassemble bowl and |

|

separator. |

has formed between |

clean it thoroughly |

|

|

distributor and sliding |

|

|

|

piston or between |

|

|

|

sliding piston and bowl |

|

|

|

bottom. |

|

|

|

Peed to bowl is hindered |

Clean distributor neck |

|

Overflow of the |

by deposits in distribu- |

|

|

bowl. |

tor neck with high |

|

|

|

specific gravity, such |

|

|

|

as rust from tanks and |

|

|

|

pipe lines. |

|

Bowl and Operating-Water Peed

Assembly-shown with regard to possible Operating Troubles

TROUBLE SHOOTING (GENERAL)

Troubles

The bowl does not come up

to rated speed or takes too long to do so.

Causes

l) Brake is on.

2) Bowl lock screws are in.

Remedies

Release brake by turning

handle 15b clockwise.

Slacken back lock screws

Causes

3) Motor is incorrectly

connected.

Remedies

See wiring diagram,

Causes

4) Friction surfaces of

clutch shoes are oily.

Remedies

Wipe dry friction surfaces

Do NOT use benzine, nor trichlorethylene,nor any other

solvent!

Causes

5) Linings of clutch shoes

are worn.

Remedies

Replace clutch shoes

Causes

6) Insufficient number of

clutch shoes.

Remedies

Add one or two clutch shoes

(see sect. 13.3).

Causes

7) Bowl is placed too high

or too low.

Remedies

Adjust to correct bowl

height

Causes

8) Liquid or sludge has

collected in the upper section of frame, resulting in slowing-down of the bowl.

Remedies

Check frame drain: liquid

must run out freely

Clean inside of upper

section of frame.

Causes

9) Clamp plates are not

tight; worm wheel slips on shaft.

Remedies

Tighten long hex head

screws in worm wheel. Tighten crosswise, by single turns

Troubles

The bowl speed drops during

operation.

Causes

l) Friction surfaces of

clutch shoes are oily

Remedies

Wipe dry friction surfaces.

Do NOT use benzine, nor trichlorethylene,nor any other

solvent!

Causes

2) Speed of motor drops

during operation.

Remedies

Inspect the motor and check

the line voltage.

Troubles

The bowl comes up to speed

too quickly (in less than 4 minutes).

Motor pulls too high a

starting current.

Causes

Too many clutch shoes are

inserted. Note that driving effect of new clutch shoes will improve after

several starts.

Remedies

Reduce number of clutch

shoes to 3 or 2. See that shoes are evenly distributed

|

Troubles |

Causes |

Remedies |

|

17.4. |

l) The separated sludge |

De-sludge bowl several |

|

Uneven run of the |

has deposited uneven- |

times (see sect. 7.4.2.

or |

|

separator. |

ly in the bowl (see |

7.4.3). |

|

|

also sect. 16.4). |

If de-sludgings do not

im- |

|

|

|

prove conditions, close |

|

|

|

the bowl and fill it with |

|

|

|

oil or water in order to |

|

|

|

suppress increased vibrations |

|

|

|

occuring during slowing- |

|

|

|

down of the bowl. Stop the |

|

|

|

separator. Apply brakes. |

|

|

|

If bowl proves to be

leaky, |

|

|

|

leave feed line open. |

|

|

|

Clean the bowl |

|

|

2) Bowl is not properly |

Assemble bowl properly

(see |

|

|

assembled or, if |

|

|

|

plant has several |

|

|

|

separators, bowl |

|

|

|

parts may have been |

|

|

|

interchanged. |

|

|

|

3) Tension of disc set |

Check if bowl lock ring

is |

|

|

has slackened. |

properly closed |

|

|

|

|

|

|

|

Check disc count. |

|

|

|

If necessary, add spare

disc |

|

|

|

or blind spare disc |

|

|

|

|

|

|

4) Bowl is damaged and, |

Send bowl to factory or |

|

|

therefore, out of |

authorized factory repair |

|

|

balance. |

shop. Do NOT attempt to make |

|

|

|

your own repairs, never

weld |

|

|

|

or solder. Bowl is made of |

|

|

|

heat-treated steels! |

|

|

5) Neck bearing springs |

Replace all 6 neck

bearing |

|

|

are weak or broken. |

springs. |

|

|

6) Pressure spring in |

Replace pressure spring. |

|

|

bottom bearing is. |

|

|

|

broken. Bowl is found |

Adjust bowl height. See |

|

|

to be about 2 mm too |

|

|

|

low in the frame. |

|

|

Troubles |

Causes |

Remedies |

|

|

7) Ball bearings are

worn. |

Exchange damaged

bearings. |

|

Uneven run of the |

|

IMPORTANT! |

|

separator. |

|

As spindle bearings use

only |

|

(cont'd). |

|

ball bearings with

increased |

|

|

|

accuracy of running |

|

|

|

|

|

|

8) Gear parts are in bad |

Clean gear chamber

thoroughly |

|

|

condition as a result |

|

|

|

of: 1. normal wear, 2.

premature wear |

Replace worm wheel

assembly with clamp plates 215a-h and at the same time worm 159d |

|

|

caused by: |

(on SAOG 3016) or worm

spindle |

|

|

a) lack of oil |

159f (on SAOG 5016).

Never replace only one gear part! |

|

|

b) oil of too low a

viscosity; |

|

|

|

|

Change oil |

|

|

c) metal abrasives |

If necessary, change oil

more |

|

|

present in the |

often. |

|

|

lubricating oil due |

|

|

|

to the following |

|

|

|

possible causes: |

|

|

|

- viscosity of oil |

|

|

|

is too low; |

|

|

|

- oil has not been |

|

|

|

changed in time; - gear

chamber has not been cleaned; |

Regarding item 2e, the

following should be kept in mind: |

|

|

d) replacement of one

gear part only; |

The operating-water

pressure must range between 28 and |

|

|

e) water breaking-in |

70 psig. Make sure that |

|

|

because operating- |

shut-off device for

operating |

|

|

water pressure is |

water is always closed

during |

|

|

too high or because |

shut-down of separator. |

|

|

operating-water valve |

If necessary, provide a |

|

|

was open for a longer |

second shut-off device. |

|

|

period during shut- |

|

|

|

down of the separator. |

|

|

|

|

|

|

Dirty-oil pump does |

l) Dirty-oil pump is

defective. |

Check shaft gaskets in

pump. |

|

not suck in. |

|

Inspect spill valve; if |

|

|

|

necessary, re-adjust. |

|

|

2) Suction lines are

clogged |

Clean or seal suction

lines. |

|

|

or leaky. |

Check bottom valve! |

|

|

3) Pre-strainer is

clogged |

Clean pre-strainer |

|

|

or leaky. |

|

|

|

|

Replace gasket in cover. |