Steam Traps

The following is intended to point out system conditions that may be encountered and the characteristics of each type of trap. Within steam systems, important considerations must be taken into account. These considerations include venting of air during start-up; variations of system pressures and condensing loads; operating pressure and system load; continuous or intermittent operation of system; usage of dry or wet return lines; and overall probability of water hammer.

Air

Venting

At

start-up all steam piping, coils, drums, tracer lines, or steam

spaces contain air. This air must be vented before steam can enter.

Usually the steam trap must be capable of venting the air during this

start-up period. A steam heating system will cycle many times during

a day and fast venting of air is necessary to obtain fast

distribution of steam for good heat balance.

A steam line used in process may only be shut down once a year for repair and venting of air may not be a major concern.

Modulating

Loads

When

a modulating steam regulator is used, such as on a heat exchanger, to

maintain a constant temperature over a wide range of flow rates and

varying inlet temperatures, the condensate load and differential

pressure across the trap will change. When the condensate load

varies, the steam trap must be capable of handling a wide range of

conditions at constantly changing differential pressures across the

trap.

Differential

Pressure Across Trap

When a trap drains into a dry gravity return

line, the pressure at the trap discharge is normally at O psig. When

a trap drains into a wet return line or if the trap must lift

condensate to an overhead return line, there will normally be a

positive pressure at the trap discharge. To assure condensate

drainage, there must be a positive differential pressure across the

trap under all load conditions..

Water

Hammer

When a trap drains high temperature condensate into a wet

return, flashing may occur. When the high temperature condensate at

saturation temperature discharges into a lower pressure area, this

flashing causes steam pockets to occur in the piping, and when the

latent heat in the steam pocket is released, the pocket implodes

causing water hammer. Floats and bellows can be damaged by water

hammer conditions.

When traps drain into wet return lines, a check

valve should be installed after the trap to prevent backflow. The

check valve also reduces shock forces transmitted to the trap due to

water hammer. Where possible, wet returns should be avoided..

Application

The design of the equipment being drained is an important element

in the selection of the trap. Some equipment will permit the

condensate to back up. When this occurs the steam and condensate will

mix and create water hammer ahead of the trap. A shell and tube heat

exchanger has tube supports in the shell. If condensate backs up in

the heat exchanger shell, steam flowing around the tube supports

mixes into the condensate and causes steam pockets to occur in the

condensate. When these steam pockets give up their latent heat, they

implode and water hammer occurs, the water hammer often damages the

heat exchanger tube bundle. The trap selection for these types of

conditions must completely drain condensate at saturation temperature

under all load conditions.

Steam mains should be trapped to

remove all condensate at saturation temperature. When condensate

backs up in a steam main, steam flow through the condensate can cause

water hammer. This is most likely to occur at expansion loops and

near elbows in the steam main.

Applications such as tracer lines

or vertical unit heaters do not mix steam and condensate. In a tracer

line as the steam condenses, it flows to the end of the tracer line

and backing up of condensate ahead of the trap does not cause water

hammer as the steam does not pass through the condensate.

Vertical

unit heaters normally have a steam manifold across the top and, as

the steam condenses in the vertical tubes, it drains into a bottom

condensate manifold. As the steam does not pass through the

condensate, water hammer normally would not occur.

A review of the trap operating principle will show how various types of traps meet the different system characteristics.

Having gone to a lot of expense in generating steam and installing a distribution system we now need to get it to it's various users around the plant as efficiently as possible. Efficiency translates into getting it to the users with a minimal loss in latent energy at a reasonable cost. This is where the steam trap comes in. Without steam traps unabated condensate would form in distribution piping, creating a wide range of problems. In addition there would be no essential control at the users. Steam would enter a set of tubes or a coil at one end and come out the other as either steam, condensate or a two-phase mixture of the two; very dangerous, damaging and wasteful.

By installing steam traps in strategic locations throughout the distribution system we can alleviate those problems. A steam trap on the outlet side of a heat exchanger allows the steam to reside there until all of the latent heat energy is transferred and the accumulated condensate is carried off. With proper placement and specification of steam traps for these purposes we can create and maintain an efficient, cost effective steam supply and distribution system. In knowing this, the next step is to determine the best trap to use for a given application. So lets take a look at the various types of traps and what each is or is not suited for.

In identifying steam traps we can break them down into three main groups: Thermodynamic, Thermostatic and Mechanical.

THERMODYNAMIC: In addition to downstream flash steam assist, this type of trap operates on the difference in velocity or kinetic energy between steam and condensate passing through a fixed or modulating orifice.

THERMOSTATIC: This type of trap operates on the principle of expanding liquids and metals used to drive a valve into or back it away from a seat.

MECHANICAL: This trap is made up of mechanical apparatus that are driven by the density of the condensate to operate a float or a bucket.

On a generic basis, let us take a look at the various types of traps within each group. Generic is used because the various manufacturers have several different designs of the same basic trapping principle. What we will discuss here are the primary trap designs in each category. For instance, within the Thermodynamic category of traps there are the orifice, disc, impulse or piston and labyrinth types. We will only discuss the orifice and disc types because of their predominance.

THERMODYNAMIC STEAM TRAPS

Orifice Type - Description

This is nothing more than a steel plate with a hole. Some are styled after a pancake blind and others are made as an integral part of a union. The basic principal behind this trap is that the expanded volume of steam compared to condensate has a throttling effect at the orifice. With a properly sized orifice, condensate, at its lower specific volume will pass through the opening at a comparatively slow velocity. As steam begins to reach the orifice plate the condensate will begin to expand. As the condensate expands, the velocity through the orifice will increase and the throttling action will start to take place. According to the laws of physics, you can have mass flow or you can have increased velocity through a fixed opening but you cannot have both.

Consequently, once steam reaches the orifice the velocity has increased to such a point that the pressure drop across the orifice creates the throttling effect. If you were to watch this in action it would appear that there is, indeed, steam passing through the orifice. What you would actually be seeing is flash steam. This occurs when condensate, at a higher pressure, is passed to a lower pressure. A portion of the sensible heat content of the condensate at the higher pressure will become latent heat at the lower pressure and flash to steam. We will discuss flash steam in more detail a little later.

About the only good thing that can be said for this type of trap is that it has no working parts to fail and it requires very little space for installation.

Disadvantages to this trap are its limited capacity range, its inability to discharge a large volume of air at startup and its tendency to be nothing more than a leak source when live steam reaches the orifice. If live steam is allowed to blow through the orifice for an extended period the orifice can become enlarged through erosion. This, over time, provides a larger, more erratic, opening. Which, in turn, provides an increasingly larger and costlier leak source.

Orifice Type - Applications

The orifice trap, although not practical as an in-service steam trap, does have its place. Where temporary steam trapping is required for a short period of time the orifice trap is an inexpensive and practical solution.

In the event that a trap has failed and a permanent replacement is not available, a calculated orifice can be temporarily installed with reduced down time and minimal expense.

If a permanent by-pass has been installed around the trap an orifice can be installed in that by-pass along with a throttling valve. This alleviates the need to blind throttle the steam when the by-pass is placed into service. The calculated orifice will automatically throttle the by-pass eliminating the need to guess at how many turns to open and set the throttling valve. Should the orifice be oversized (a probable indication would be water hammer in the receiving condensate line) the installed throttling valve can serve as backup to correct it.

Disc Type - Description

Aside from the orifice trap this is probably the simplest trap on the market and yet is the most widely used. The disc trap is made up of three primary components: the body, the cap and the disc. Like the orifice trap, the operation of the disc trap utilizes the difference in specific volume between steam and condensate. With flow moving through a fixed orifice this translates into a difference in velocity between steam and condensate. Operation of the disc trap also utilizes flash steam as an operating force to work in conjunction with the velocity of the steam.

In order to understand the operation of the disc itself we have to know the principle under which it operates. Bernoulli's Principle, simply stated: THE PRESSURE OF A FLUID (LIQUID OR GAS) DECREASES AT POINTS WHERE THE SPEED OF THE FLUID INCREASES.

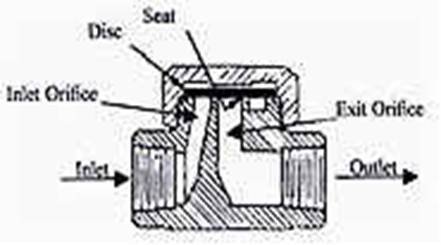

Applying this to the disc trap we are, in fact, creating a low pressure zone between the disc and seats whenever we increase the velocity of the steam or condensate flowing through this zone. In addition we are providing a small chamber for the accumulation of flash steam above the disc. Fig. 1 shows a simple disc trap. As flow, in the form of condensate, moves into the trap and through the inlet orifice it forces the disc to lift, allowing the condensate to pass through and out the outlet. As the temperature of the condensate reaches it's saturation point a percentage of that condensate will flash as it exits the inlet orifice. When steam reaches the inlet orifice two things will immediately happen: the velocity will increase sufficiently to create a low pressure zone between disc and seats pulling the disc down upon the seats. At the same time flash steam will have formed behind the disc and, with the exit orifice sealed off, the pressure induced by this non-escaping flash steam will hold the disc in place. The disc will remain in place until the flash steam has condensed, thus allowing the disc to open again.

Fig. 1

Thermodynamic Disc Trap

You can see by this that the governing factor behind the operation of the disc trap is the flash steam. The amount of condensate that accumulates upstream of the trap is dependent upon the amount of time the flash steam remains in that state. This, in essence, is what regulates operation of the trap.

Since the flash steam is contained in the cavity under the cap the length of time that the flash steam exists as such depends on the amount of heat transfer through that cap If we were to watch an uninsulated disc trap, open to grade, on an outside installation we could observe the change in the frequency of cycles the trap would go through from summer to winter. Providing that the only change in heat transfer rate is caused by the change in ambient temperatures the cycles in the winter would be more frequent than in the summer owing to the additional heat loss in the colder temperature. This would, at the same time, compensate for the added heat transfer load that the unit being trapped would realize.

Unlike the mechanical traps that follow, the cycle of this type of trap depends on the condensing rate of the flash steam that keeps the disc closed. By performing a simple test, of pouring water over the cap of a trap discharging to atmosphere, we can see abruptly, the change in the cycle of the trap as it quickens. Inversely we can put an insulation cap on the trap and see the cycles slow. It is obvious that the discharge of condensate is dependent upon the resident time of the flash steam in the disc chamber and not on the build-up of the condensate itself.

With that in mind, allowances regarding the upstream length (or more appropriately, the capacity) of the piping will have to be made for the installation of the disc trap. The trap itself is very compact, which adds to its popularity, but does not allow it to store condensate. Any build-up in condensate will take place in the piping upstream of the trap. Consequently the smaller the pipe and the more condensate that accumulates between cycles, the further upstream the condensate will backup. If the trap is inadvertently insulated it will compound the situation by not allowing the flash steam, holding down the disc, to condense more readily allowing the condensate to pass.

In too many cases the disc trap has been installed as close as possible to the drip leg which puts it in close proximity to the unit it is trapping. If you have access to equipment, particularly unit heaters, that are using a disc trap mounted within approximately 6" of the drip leg and they have been installed in this manner for several years please inspect them. What you are likely to find is a corrosion problem that will be apparent by leaking at pipe joints and within the lower section of the unit heater coils. With a little research you may even find that in some of the older locations, units have been replaced or repaired one or more times.

The cause of this is the continual backup of condensate, under pressure, into the piping and equipment. As mentioned earlier this condensate can be very corrosive if not removed quickly. Allowing the condensate to repeatedly backup into the piping and equipment is essentially the same as allowing it to reside there. In addition, by allowing the condensate to backup into the equipment the heat transfer efficiency of the unit will fall off proportionately to the area that is flooded.

In most cases placing the trap 12" to 18" from the drip leg will provide enough of a reservoir to prevent condensate from backing up into the equipment. If there are space constraints keep in mind, the distance from drip leg to trap does not have to be in a straight line.

Disc Type - Application

This type of trap is an excellent general service trap that can be specified for both saturated or super heated steam. Although it operates well throughout a wide pressure range please verify its low pressure limitations with the manufacturers literature. This trap will have a low pressure limit that it will need to exceed in order to pass condensate. Nor should it be used where steam throttling could fluctuate pressure at the trap to near atmospheric pressures. Within its capacity range this is an excellent trap for a wide range of applications.

The disc trap is lightweight, compact, easy to install, easy to maintain, withstands water hammer and is relatively less expensive than other types of traps. When a slow warm up is part of the start-up procedure it is an excellent trap for automatic start-ups. If, during start-up, steam is introduced suddenly to a system, without benefit of a warm up cycle, the rush of air preceding the condensate and steam to the trap will create enough velocity across the trap seating surface to force the disc to close. Disabling the system in this manner is referred to as air binding. Since there is no flash steam to keep the disc closed the disc will have a tendency to flutter, or chatter. Although it will continue to discharge air it will prevent the trap from discharging it at the necessary rate.

In the case where steam is introduced without warm-up it is recommended to either provide additional valving for blowdown during start-up or specify a different type trap altogether.

There is a tendency to consider the disc trap as self-draining. In the event that the steam supply is shut off to the trap, the trap installed in the vertical and the discharge down and open to atmosphere, it is suggested it will drain any remaining condensate. This of course is a major consideration when designing for freeze protection.

What actually occurs when the supply of steam is shut off is the following: the steam remaining in that isolated section of pipe will continue to condense. Initially the disc in the disc trap will remain open. With some residual pressure still in the line condensate will continue to drain through the trap. As the steam condenses and its volume collapses it will attempt to draw in outside air to replace that lost volume. When this occurs the displacement air will be pulled in through the trap orifice, its only path in. As the displacement rate increases the velocity of air will force the disc down onto the seat to close off that section of pipe or tubing between the steam shut-off valve and the trap. With that section of piping closed off the condensing steam will create a vacuum essentially locking the disc in its closed position. With residual condensate remaining in the line that section now has the potential to freeze.

There are three general ways of preventing this. One is to install a vacuum break in a high point between the shut-off and the trap. The second is to install an ambient sensing valve in a low point between the shut-off and the trap. Both of those methods will control the situation automatically. The third is to install a low point, manual drain valve between the shut-off and the trap.

There is also a fourth method to be considered. Armstrong manufactures a valve that operates as an automatic low point drain. It operates essentially like a vacuum breaker with a set point at 5 PSIG. It is simply a ball check in which the ball remains in its seat as long as the steam line is under pressure. The ball is under 5 pounds tension from a spring that is attempting to push the ball off of its seat. If steam pressure is shut off to the line and the in-line pressure drops to 5 PSIG or less the valve will open to drain the accumulated condensate.

THERMOSTATIC STEAM TRAPS

Balanced Pressure Type - Description

The Balanced Pressure type trap operates on the principal of liquid expansion due to an increase in temperature. The liquid is contained in a bellows (Fig. 2) internal to the steam trap and fixed at one end. Integral to the bellows is a valve attached to its free end.

The liquid in the partially filled bellows can be as simple as distilled water under vacuum or an alcohol combination to reduce its vapor point to a lower degree than water. At ambient conditions the bellows is contracted with the valve away from the seat. When steam, or condensate near it's saturation point, comes in contact with the bellows the liquid inside the bellows expands and drives the valve into the seat closing off steam flow.

As the steam condenses, collects and cools, the bellows will cool and contract, backing the valve away from the seat and allowing the accumulated condensate to pass. As the condensate passes through the trap and is replaced by steam the bellows heats up again. As steam comes in contact with the bellows it expands and closes the valve, shutting off flow. As you can see this trap is not governed not only by the pressure differential but rather by the temperature of the steam and condensate.

Fig. 2 - Balanced Pressure Thermostatic Trap

Balanced Pressure Type - Application

This trap is excellent on start-ups, automatic or manual. It remains in its full open position allowing for the removal of air and condensate until steam comes in contact with the bellows. Additionally it is a relatively small, lightweight trap that handles a wide range of condensate loads over a wide range of pressures. One concern with this trap is its susceptibility to water hammer. When specifying this type of trap, consider the potential for water hammer if the trap discharges into a common header or sub-header. If that potential exists specify a check valve to be installed downstream of the trap and prior to its connection to a common header.

Although there are designs of this type of trap that will operate in super heated conditions it is generally not recommended for that service. If you feel the need to use this trap in super heated service check the manufacturers recommendations before specifying.

Applications include drip legs, heating coils, steam tracers and various process requirements. Consideration, as in the disc trap, must be given to providing sufficient upstream piping capacity for the accumulation of condensate. As with the disc trap, the designer should provide an upstream reservoir sufficient enough to contain the residual condensate preventing it from backing up into equipment. A 12" to 18" run of pipe, in most cases, should be sufficient. If the possibility exists for the flow rate of condensate to fluctuate to a point at or above the capacity of the trap a longer or larger diameter section of pipe may be required in order to contain the condensate between the trap and equipment.

Fig. 3 - Bi-Metallic Thermostatic Trap

Bi-Metal Type – Description

Like the Balanced Pressure trap, the Bi-Metallic trap is also governed by temperature variations. However, as the name suggests it does so by utilizing the differing expansion rates of metals when exposed to temperatures above or below ambient.

By laminating two dissimilar metal strips and exposing the resulting composite to elevated temperatures the differing expansion rates of the composite metal strip will cause it to bow. The higher the temperature the more extreme the bow.

The reaction of the Bi-Metal composite is utilized in several different forms with various valve and seat arrangements. The two most widely used designs are variations of the bellows style. One uses Bi-Metal circular discs. The two sets of Bi-Metal laminates are joined at the perimeter with the metal layer of each Bi-Metal disc having the lower rate of expansion facing each other. Several sets of these joined discs may be stacked to increase the force applied when they expand.

Through the center of the stacked discs is a rod, which is attached to the upper most disc. The rod runs through the sets of discs then through a seated orifice. At the end of the rod is a valve. In the relaxed or ambient condition the discs are flat against one another. In their hot condition each set expands against itself causing the bellows to expand. As the bellows expands it draws the valve into the seat of the orifice blocking off the flow of steam.

Bi-Metal Type – Application

Like its Balanced Pressure counterpart, this trap is excellent on start-ups, automatic or manual. It remains in its full open position allowing for the removal of air and condensate until steam comes in contact with the Bi-Metal element. Additionally it is a relatively small, lightweight trap that handles a wide range of condensate loads over a wide range of pressures. The Bi-Metal trap is more resistant to water hammer than the Balanced Pressure trap. This makes it a good alternative when a thermostatic trap is the first choice and the potential for water hammer exists.

Applications include drip legs, heating coils, steam tracers and various process and utility requirements. Consideration, as in the disc trap, must be given to providing sufficient upstream piping capacity for the accumulation of condensate. As with the disc trap and the Balanced Pressure trap, the designer should provide an upstream reservoir sufficient enough to contain the residual condensate preventing it from backing up into equipment. A 12" to 18" run of pipe, in most cases, should be sufficient. If the possibility exists for the flow rate of condensate to fluctuate to a point at or above the capacity of the trap a longer or larger diameter section of pipe may be required in order to contain the condensate between the trap and equipment.

Liquid Expansion Type – Description

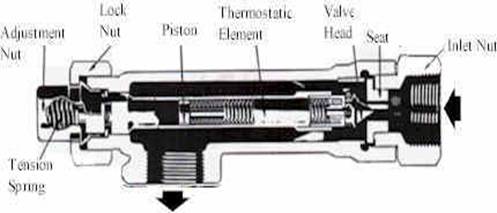

This type of trap, like the other thermostatic traps, is designed to respond and control the release of condensate relative to the temperature of that condensate. This trap (Fig. 4) contains an oil-filled cylinder encasing a sealed bellows with an enclosed piston driven rod with a valve on one end. When the temperature of the condensate, flowing through the trap housing, begins to rise the oil in the cylinder begins to expand in response. As the oil expands it drives the rod assembly toward a valve seat located in the inlet of the trap body. As the condensate surrounding the cylinder cools down the oil contracts allowing the rod assembly to retract from the valve seat. Condensate begins to flow until it heats sufficiently to close the valve again.

The Liquid Expansion Trap also has an adjustable nut on one end. This allows the set temperature to be adjusted within the operating range of the trap.

Fig. 4 - Liquid Expansion Trap

Liquid Expansion Type – Application

The Liquid Expansion Trap has limited use in trapping steam. It releases condensate at or below an adjustable set point of 212° F. Normal operation subjects the piping and equipment upstream of the trap to condensate flooding. In some situations this is acceptable. This trap cannot respond to a wide fluctuation in steam and condensate temperatures either. The type of service this trap is most suited for would be something on the order of maintaining a storage tank temperature. A condition that is constant and does not require response to sudden changes in heat transfer rates or continual wide shifts in temperature.

MECHANICAL STEAM TRAPS

Inverted Bucket Type – Description

Next to the Disc Trap this is the most widely used trap in the industry. It can arguably be said that this trap is overused. It has such a wide use range that it is probably specified out of misunderstanding in a large number of situations. These aren't necessarily situations where this type of trap wouldn't work but rather situations where a less expensive, smaller, possibly longer lasting type of trap could have been applied.

This trap (Fig. 5) operates on the principal of an inverted water glass (the component referred to as the bucket). The air and CO2 entrapped in the inverted bucket provides buoyancy keeping the inverted bucket in its raised position. Extending partially inside this inverted bucket is a dip tube, which is where the condensate and steam enter. In the top of the inverted bucket is a vent hole. This allows air and CO2 to continually discharge. Attached to the top of the inverted bucket is a lever and valve assembly, which is attached to a valve seat insert.

On start-up, the initial surge of condensate, which precedes the flow of steam, will provide the liquid prime needed to make the Inverted Bucket trap work. That prime is what seals the bottom open portion of the bucket. Without it, steam would enter the bucket through the dip tube flow out the bottom of the inverted bucket and pass through the outlet. At times, due to transient surges, super heat conditions or a transient vacuum condition, a trap may lose its prime. An obvious indication of this is a sudden water hammer problem in the condensate return system due to the trap allowing steam to blow through because the water seal is not there to retain the steam.

The trap operates by entrapping steam in the prime sealed inverted bucket as it enters through the dip tube. As the steam resides in the inverted bucket it condenses. At this point there are two issues that have to be resolved in order for the trap to function properly: 1. As the steam condenses inside the bucket, a portion of the air and CO2 dissolved within the condensate has to be released. If the CO2 is not released from the condensate, and remains dissolved, it forms carbonic acid having a detrimental effect on carbon steel, cast iron and bronze material; 2. If the released air and CO2 are not evacuated they will accumulate until they bind the trap, preventing it from functioning.

In order to evacuate the released air and CO2 a vent hole is provided in the top of the inverted bucket. The hole is sized to allow the air and CO2 to escape the bucket and flow out through the discharge at a rate that will insure that a residual amount remains to help maintain buoyancy for the bucket.

A proportional volume of air and CO2 inside the bucket keeps the bucket raised, keeping the valve closed. As the condensate accumulates and displaces the volume of air and CO2 it reaches a point at which the bucket can no longer sustain its buoyancy. At that point the bucket drops pulling open the valve and allowing condensate to flow out through the discharge.

This trap is specified based on the differential pressure between the inlet and outlet pressures of the trap. With the length of the valve lever fixed the differential pressure is used to determine the weight of the bucket. The result allows the bucket to lift and reset the valve after dumping its condensate. The calculated weight of the bucket also allows the bucket to drop against the upstream pressure when it's full of condensate.

Fig. 5 - Inverted Bucket Trap

Inverted Bucket Type – Application

As indicated earlier, the Inverted Bucket Trap is used for a wide range of applications. It has such a general use range that designers, engineers, mechanical contractors and maintenance personnel tend to gravitate to the Inverted Bucket as a reflex rather than through a determining process. Because of this there is money being wasted not to mention misapplication in size and function.

In services where a 1/2" Disc Trap could have been specified 1 1/2" Inverted Bucket Traps have been installed. In too many cases like that it is apparent that whoever specified those steam traps didn't know what they were doing. If you don't know what you are doing or your not sure, contact one or more steam trap manufacturing representatives. But, as always, when working with someone who is trying to sell you something, DO YOUR HOMEWORK. Be ready to both ask questions as well as provide them with proper, concise information. They would much rather help you size and match the trap for the application than repeatedly get called back for something that doesn't work properly. They're in business to make money and they can't do that by spending time at your facility replacing poorly specified traps or by loosing customers due to ineffective engineering assistance.

The Inverted Bucket Trap can be used over a wide range of pressures and temperatures to trap process and utility equipment, as a drip trap and in selected HVAC service. It can be installed inside or outside. However, if an Inverted Bucket Trap is specified for outside service in a freezing environment, a stainless steel type would be highly recommended. These encapsulated traps, like Armstrong's model 1010, have the capacity, due to their material of construction, to withstand inadvertent freeze ups. When condensate inside the trap freezes, the trap expands like a balloon. Once thawed it goes right back into service.

Should this occur it is always a safe bet to replace the trap at the next opportune time. It isn't suggested that these traps be placed into a potential below freezing environment without freeze protection. On the contrary, if the possibility of freeze up exists then the designer should take steps to configure the installation, heat trace the trap and piping or otherwise design an installation that protects the trap from freeze up. However, these stainless steel encapsulated traps are an excellent final protection against having to shut down a line or system because several steam traps ruptured and have to be replaced.

Float & Thermostatic Type – Description

As the name implies, the Float & Thermostatic Trap utilizes two individual mechanisms that operate in conjunction with one another. The float operates a valve (Fig. 6) that controls the discharge of condensate. The thermostatic element controls the release of air and CO2. The float itself, which is normally a ball type, is located in the lower portion of the trap body. It is attached to a rod which is, in turn, attached to the body of the trap in such a way that it is free to pivot about that point, allowing the float the freedom to move vertically. Near the end where the rod is attached to the body a valve is attached to the rod. The valve is positioned so that when the float is at rest the valve is seated in the outlet of the trap.

The thermostatic element is located in the upper part of the trap body. One end of the element is fixed allowing the opposite end with an attached valve to move in and out of a seated vent discharge opening located in the body of the trap. That vent discharge is connected to the discharge for the condensate. In its relaxed position the valve is pulled away from the seat.

With the trap out of service the float rests in its bottomed out position, with the valve closed. The thermostatic vent element is in its contracted position with its valve open. As steam is introduced to the system and begins to move through the piping it will force the volume of air in the piping out ahead of it. This air is forced out of the system through the opened thermostatic vent. Depending upon the length of the piping the steam will initially condense in the piping before it gets to the trap. As the condensate enters the trap and begins filling the trap body the float will rise pulling the valve off of the discharge seat. This allows the condensate to be removed immediately.

With the thermostatic vent and the condensate discharge both in their open positions steam begins to enter the trap. As this happens the heat of the steam causes the thermostatic element to expand closing off the vent orifice. However, as long as there is a sufficient condensate level in the trap the condensate outlet orifice will remain open. This trap is self-regulating. It does not go through the fill/discharge cycles like most other traps. If the condensate enters at a constant rate it will discharge at a continuous and constant rate.

As the steam condenses the released air and CO2 will accumulate at the top of the trap, around the thermostatic vent. This provides an insulation barrier from the heat of the steam allowing the thermostatic vent to cool down sufficiently to contract, opening the vent discharge orifice. As the air and CO2 are released steam replaces that volume and again comes in contact with the thermostatic element causing it to expand, closing off the discharge orifice.

When using an ultrasonic listening device it is difficult to determine if this type of trap is working properly. Since there is no fill & dump cycle, which is easily recognizable and is used on most traps to determine condition, only a trained ear can tell whether or not a Float & Thermostatic Trap is operating properly.

Fig. 6 - Float & Thermostatic Trap

Float & Thermostatic Type - Application

This trap can be used in Process and utility applications as well as HVAC service. It is a good choice for high capacity requirements. However, it does not stand up well in conditions where the trap may be subjected to water hammer and/or freeze up. The float and thermostatic element can be damaged by water hammer and the float can be damaged by freeze up. If selected, given those considerations, this is an excellent multi-use trap.