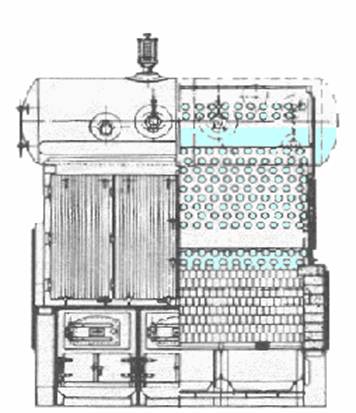

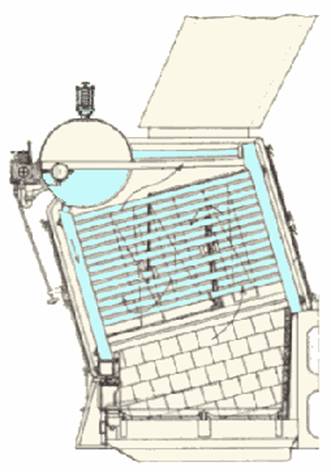

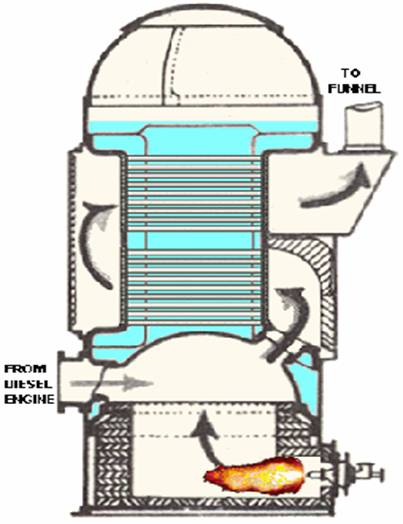

The boiler has a dome-shaped furnace top that forms the bottom of the boiler itself. It has a neck on the front through which the boiler is fired and there is another on the rear part of the top that leads to a higher located combustion chamber. The combustion chambers backside is covered with brickwork and from its front-side a horizontal bank of flue-tubes leads to the smoke box on the front side of the boiler.

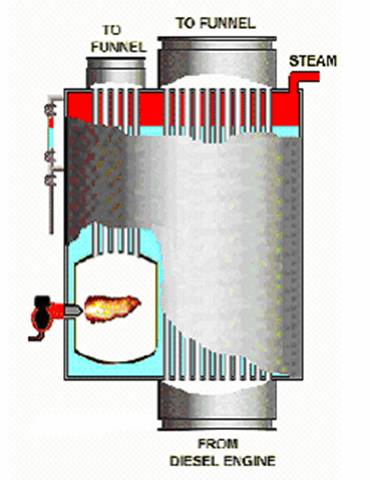

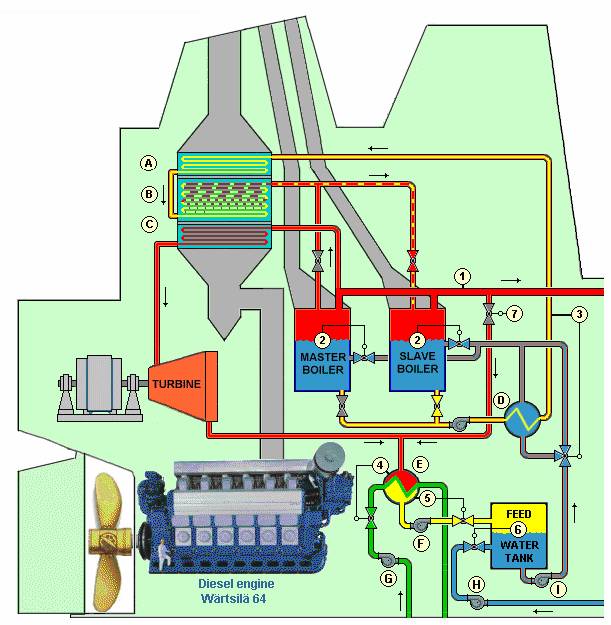

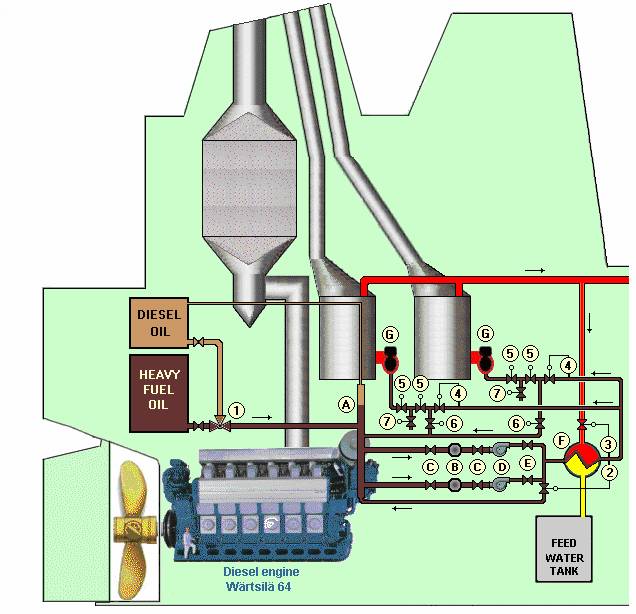

The composite marine steam boiler is a combination of an oil-fired steam boiler and an exhaust gas economizer. When the diesel engine is at full load the fuel oil burner only starts if the steam demand exceeds the steam production achieved from the diesel engines exhaust gases.

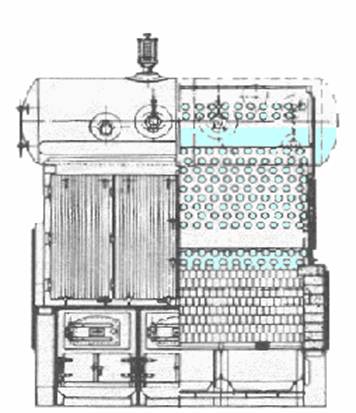

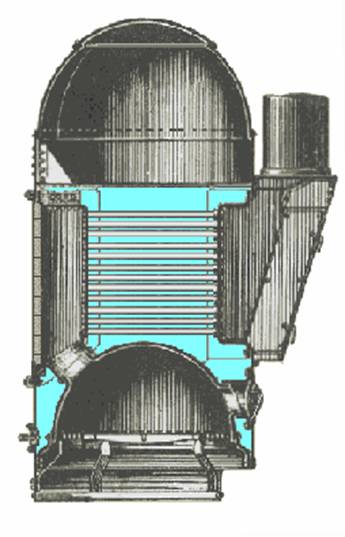

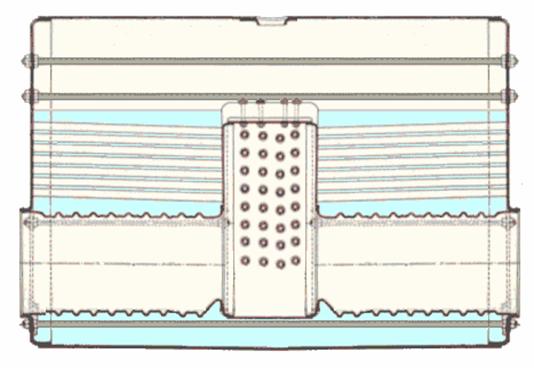

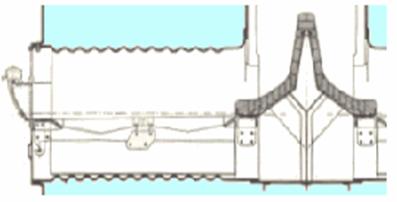

The single-ended return tube Scotch boiler consists of a cylindrical boiler shell of large diameter and short length, provided with two or more furnaces in corrugated fire-tubes. Each furnace ends in a combustion chamber, surrounded by water. The gases pass through a bank of flue-tubes from the combustion chamber to the smoke-box at the boiler front

The Scotch fire tube boiler contained a large quantity of water, about six times more than a water-tube boiler, and was therefore slow to steam up and to change the output capacity. Due to the boilers stiff construction it required also a long steaming up period to avoid leaks caused by thermal expansion of the material.

When the furnace door was open, cold air could hit the combustion chambers opposite wall and cause tube leakage. To prevent that a high baffle of firebrick was installed in the middle of the combustion chamber.

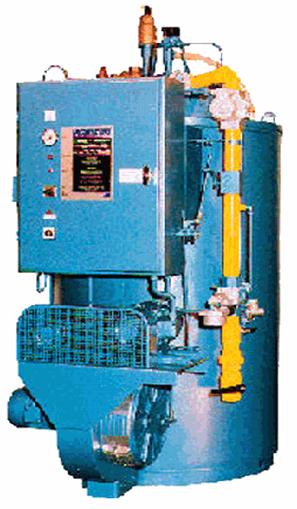

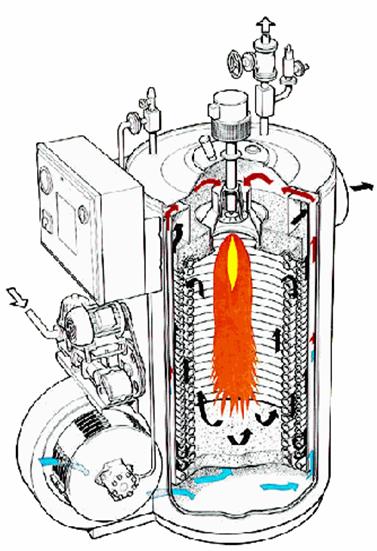

The

Vaporax steam generator

Because

of the innovative design, the rise to working pressure can take place

in 3 minutes starting from a cold boiler in stand-by. This

characteristic as well as the low volume of water reduces the thermal

losses and therefore helps to keep the operating costs low.

B.

Economizer

A heat exchanger that transfers heat from Boiler Flue

Gases to Boiler Feedwater.

C.

SteamOutlet

Saturated steam from the SteamDrum to the Superheater

D.

Cyclone

A device inside the drum that is used to prevent water and

solids from passing over with the steamoutlet.

H.

Superheater

A bank of tubes, in the exhaust gas duct after the

boiler, used to heat the steam above the saturation temperature.

I.

Superheater Headers

Distribution and collecting boxes for the

superheater tubes.

L.

Waterwall Header

Distribution box for waterwall and downcomers.

N.

Waterwall

Tubes

welded together to form a wall. ![]()

O.

Waterwall Header

Distribution box for waterwall and downcomers.

R.

Waterwall Header

Collecting box for waterwall and risers.

S.

Riser

Tubes in which steam is generated due to high convection or

radiant heat. The water-steam emulsion rises in these tubes toward

the steamdrum.

T.

Downcomer

A tube through which water flows downward. These tubes

are normally not heated, and the boiler water flows through them to

supply the generating tubes.

U.

SteamDrum

Separates the steam from the water.

V.

Economizer Header

Distribution box for the economizer tubes.

A.

Economizer section

Preheats the circulating water before it enters

the evaporator tubes.

B.

Evaporator section

Water evaporates and emulsion of steam and

water flows back to the boiler.

C.

Superheater section

Superheats the steam for the turbine.

D.

Heat exchanger

Preheats the boiler feedwater.

E.

Condenser

The exhaust steam from the turbine and excess steam from

the steam system condense and recycle.

F. Condensate pump

G.

Cooling water pump

Seawater.

H.

Make-up water pump

From softener unit.

I. Boiler feedwater pump

1.

Steam pressure control

The pressure control loop adjusts the

burner load according the steam demand.

2.

Water level control

A simple control loop will do for a boiler

with large amount of water and relatively small steam output. To

minimize shrink and swell at start and stop of the burner it would be

wise to have two setpoints for the water level. A lower level (abt.

40%) when the burner is stop and a higher (abt. 50%) when it's

firing.

3.

Economizer inlet temperature control

The feedwater is pre-heated

in order to increase the efficiency of the plant. The circulating

water to the exhaust gas boiler heats the feed water and the

three-way valve on the inlet to the heat-exchanger controls the

temperature. The economizer inlet temperature must never fall below

135°C to avoid corrosion on the economizer tubes.

4.

Condenser pressure control

An absolute pressure transmitter and a

controller adjust the cooling-water to the condenser to protect the

condensate from being cooled down more than necessary.

5.

Condenser level control

The level controller actuates the

condensate outlet control valve.

6.

Feedwater tank level control

The level controller actuates the

make up water control valve.

7.

Steam dump control valve

Takes care of excess steam from the

waste heat boiler when the steam production exceeds the steam demand.

A.

Fuel Oil header

The Fuel Oil header should be a standing up

relatively large pipe with a deaeration pipe to a higher level than

the fuel oil service tanks; some times it's connected to the top of

the diesel oil service tank.

B.

Fuel Oil filters

Clean the Fuel Oil filter frequently. If the

filters are clogged the fuel oil might vaporize in the pump and cause

damage. A differential pressure meter across the filter would be a

good help to have the filters cleaned in time.

C.

Shut off valves

Shut off valves for cleaning of the filters. The

valves should normally be open.

D.

Fuel Oil pumps

Each pump should have sufficient capacity to run

both boilers on maximum load. Normally one pump is running and the

other is standing-by. The stand-by pump should start upon low

pressure in the process line rather than being started upon a pump

motor failure.

E.

Shut off non return valves

These valves have to be non-return

type, or a shut off valve and a non-return valve. The valves should

always be open on both pumps, so the stand-by pump can start

automatically.

F.

Fuel Oil heater

The fuel oil heater is a heat exchanger that must

have a safety relief valve.

Always install a safety relief valve

if a fuel oil volume can be shut up and heated.

G. Burners

1.

Change over valve, Heavy Fuel Oil to Diesel Oil

The three-way

valve ought to be provided with a limit switch that breaks the

electric circuit and shut off the fuel oil heating valve, in the

control loop 3 , avoiding the diesel oil from being heated over its

flashpoint.

2.

Fuel oil pressure control

The pressure control loop adjusts the

fuel oil pressure by means of the pressure controller and the fuel

oil return valve. The pressure is measured after the fuel oil heater

to get accurate pressure to the burners. The return valve before the

fuel oil heater recycles cold fuel to protect the pumps from

overheating.

3.

Fuel oil temperature control

The temperature control loop adjusts

the fuel oil temperature by means of the temperature controller and

the steam inlet control valve. The temperature controller's set point

should be set to assure an adequate fuel oil viscosity for the actual

burners.

Sometimes the control valve is installed in the

condensate outlet line. This requires a smaller control valve and the

control function works even better. However, this installation is for

some reason not so very common.

4.

Fuel oil flow control

On large boilers the fuel oil flow

controller gets its setpoint from the burner management system or the

airflow controller to achieve a proper air-fuel mixture.

On

smaller boilers the fuel oil flow control valve often is connected to

the combustion air damper by means of a metal rod or wire.

In

both cases the steam pressure in the boiler sets a suitable fuel oil

flow.

5.

Fuel oil shut of valves

Almost every classification society and

other authorities requires two shut of valves for the fuel oil,

mechanically in series and electrically in parallel.

6.

Fuel oil recirculation valve

This valve does not always exist,

but if it does, the valve should open when the fuel oil shut of

valves closes. The recirculation has advantages and disadvantages.

· The advantage is that it keeps the fuel oil line warm when the burner is off.

· The disadvantages is that it will, in the long run, heat up the fuel oil passing through the oil pump that might cause problem with cavitations.

Leading the recirculation fuel oil back to the fuel oil service tank wouldn't be wise. The fuel oil's temperature often exceeds 120ºC and water that might occur at the bottom of the tank will vaporize and in worst-case cause damage to the tank.

7.

Fuel oil drain valve

Some authorities require a drain valve to be

installed between the shut off valves. The burner management program

mustn't open the drain valve before the shut off valves are totally

closed and it should close the drain valve before the shut off valves

open.

The

marine steam boilers on board in ships nowadays have become a less

evident part of the engine room than they were in the old days.

However, the marine steam boilers are still important parts of the

system, especially if the main engines are running on heavy fuel oil

that need to be heated. I don’t want to go through the entire

instruction book for the marine boiler but just point out one

important matter.

As we all know, a very thin layer of oil on the

surface of the boiler tubes or any of the direct heated surfaces of a

boiler might cause local overheating of the material and possible

damage to the boiler. What we maybe not know is how very small

quantity of oil it requires to get a dangerous situation. A tube

break in a fuel oil heat exchanger is very easy to detect, a simple

detector in the hotwell will manage that, but a small crack in a tube

may cause you an even more serious problem.

A tiny oil leakage

giving some 15 to 25 ppm of oil in the boiler feedwater would not be

visible; the water is still limpid. Yet this apparently insignificant

oil pollution might causes sever danger to the boiler. If a boiler

has a capacity of 20 tons of steam per hour at full load and the feed

water is polluted with 25 ppm of oil, then it will accumulate

approximately 12 kg oil in the steam drum per day. A bucket of oil in

the boiler every day; I suggest that you buy yourself a sensitive oil

detector.

It will cost you, but it might save you from some

future cost of repairs.

N.B. ppm=parts per million.

1

ppm=1kg per 1000 metric tons or

1 ppm=2 lb. per 1000 short tons.

An oily ring inside the water gauge glasses at the water level is a serious warning.

The mineral and organic substances present in natural water supplies vary greatly in their relative proportions, but are principally comprised under the carbonates, sulphates and chlorides of lime, magnesia and sodium, iron and aluminum salts, silicates, mineral and organic acids, and the gases oxygen and carbon dioxide.

Scale is formed from the carbonates and sulphates of lime and magnesia, and from the oxides of iron, aluminum and silicon and it will result in:

Reduction in the boiler efficiency because of the decreased rate of heat transfer.

Overheating and burning of tubes resulting in tube failure.

Scales

are dangerous long before it reaches this thickness.

A very thin

scale can cause tube failure due to overheating.

Scale has about

one-fortyeighth of the heat conductivity of steel.

A scale

thickness of about 1 mm (0.04") can be sufficient to reduce the

heat transportation to a dangerous point; when the water inside the

tube cannot receive and carry away the heat fast enough from the tube

metal to keep its temperature below its fusion temperature, resulting

in the tubes "burning-out".

Using an open or direct contact feed water heater, where the water is raised to near-steam temperature is the most effective, the cheapest and the most convenient system of de-aeration.

Heating boiler feedwater by means of exhaust steam effects a saving of about 1% of fuel for each 6ºC rise in the temperature of the feedwater. Consequently, heating the water from 10° to 99ºC saves about 14% fuel.

Besides the fuel saving, heating the feedwater increases the actual steaming capacity of the boilers. Using surplus of exhaust steam, above that required for heating the boiler feedwater, to heat buildings will realize additional economies. If all of the exhaust steam from engines or turbines can be utilized for heating during the heating season, it will pay to shut down the condenser.

The first and most important use for the exhaust steam is to heat the feedwater, since all of the heat of the exhaust steam so utilized returns undiminished to the boilers.

Lesser temperature difference at the feedwater inlet to the steam boiler reduces thermal stress in the material.

Higher feedwater temperature reduces the shrinks and swell in the steam drum and simplifies the water level control.

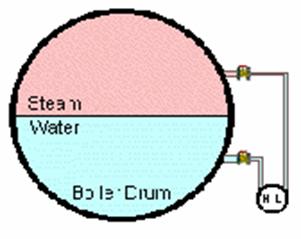

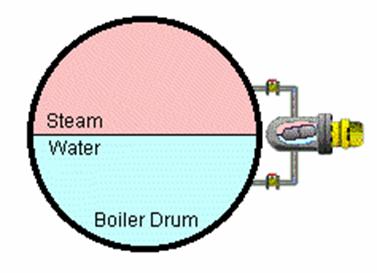

Differential

pressure measuring transmitter.

This method uses normally a

differential pressure measuring system with "wet leg", that

is, the impulse pipes to the positive measuring point below the

lowest water level and the impulse pipe to the negative measuring

point above the highest water level, are both filled with water. The

differential pressure signal is normally elevated so the output

signal corresponds to the level in the boiler. 0% of water in the

level glass correspond to 4 mA (3 psi) and 100% corresponds to 20 mA

(15 psi). The measuring result is insensitive to foam in the boiler

drum since the measuring method is based on the weight of the water.

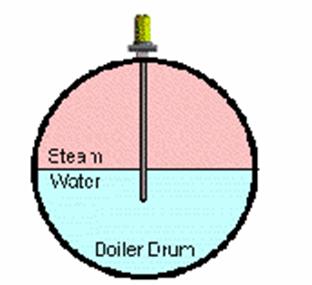

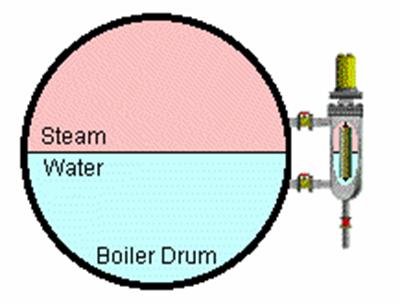

Capacitance measuring electrode transmitter.

An

insulated electrode is placed in the boiler and the length should be

sufficient to reach the water at all acceptable levels. The insulated

electrode and the boiler work as a capacitor with the water and the

steam as a variable dielectric medium. The capacitance of the

”capacitor” is converted into a current signal. 0% of

water in the level glass corresponds to 4 mA and 100% corresponds to

20 mA. The measuring result is rather sensitive to foam in the boiler

and deposits on the electrode influences negatively on the measuring

results.

This method is relatively new as level control in steam

boilers although it has been used for a long time for dry substances

such as grains in warehouses.

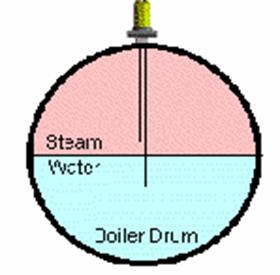

Conductivity measuring electrode level switch.

An

electrode is placed in the steam dome and the length of the electrode

decides the level where the alarm shall occur. A low voltage

alternating current passes through the water in the boiler to the

electrode and the circuit breaks when the water level falls below the

end of electrode. This method is mainly used for high and low level

alarms. It is also used, in small size boilers, to start and stop the

feed water pumps. Deposit on the electrode is not a problem. Normal

degree of coverage does not disturb the measuring results. The

measuring result is sensitive to dense foam in the boiler.

It’s

normally one electrode for emergency low water level alarm, or two

electrodes if also high level alarm is required. This water level

sensing method is also common on small boilers for start and stop of

the feed water pumps. Up to six electrodes can be used in one

electrode stand

Level float switch.

Level

float switches have been used for decades as level switches in

boilers, but nowadays electrodes have replaced them. Moving parts are

hard to check in boilers and deposit on the hinge may seriously

disturb the function. The measuring result is rather insensitive to

foam in the boiler.

Level displacer transmitter.

A

level displacer (a float heavier than the water) is suspended to a

spring balance by means of a stainless steel cable or a rod. When

semi-submerged the weight of the displacer changes when the water

level varies and the change in weight is converted into a level

signal that corresponds to the level in the boiler. 0% of water in

the level glass correspond to 4 mA (3 psi) and 100% corresponds to 20

mA (15 psi). This level measuring method is not so very common

onboard ships since the measuring result is very influenced by the

ship’s movement. Ashore, on the other hand, it works very well.

In

a boiler drum exist water and steam at saturation pressure and

saturation temperature. Furthermore, the water is mixed with steam

bubbles in different sizes. If one opens the valve to a steam

consumer then the pressure in the boiler drum falls and hence the

steam bubbles expand and the water level rises despite the fact that

the water mass actually decreases. On the other hand, pumping in cold

feed water will cause the steam bubbles to collapse and the water

level falls when the water quantity actually increases in the steam

drum. These shrinks and swell phenomena will complicate the control

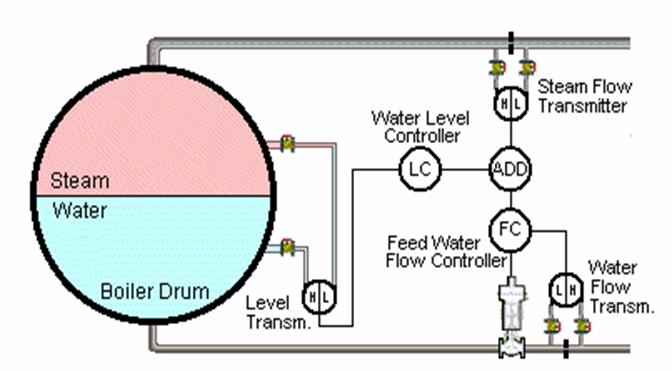

of the boilers steam drum level.

For a boiler with large amount

of water and relatively low steam production a single water level

transmitter on the steam drum is sufficient for the level controller

to maintain a level with acceptable variation.

Far more

sophisticated methods are required for boilers with high steam

production and relatively small water volume. The classic method

works as follow: The outlet steam-mass is measured and the inlet

feed-water-mass is adjusted to the very same amount. The level

transmitter is merely used to tune up the system so the water level

lies within the limits.

Thus, the setpoint to the feed water flow

controller is the sum of the outlet steam flow signal and the

reversed water level controllers signal minus 12 mA (or 9 psi if it

is a pneumatic system).

Add to the monthly maintenance list:

Check the process impulse piping between the steam outlet line and the steam flow transmitter. Fur deposit is very common in the orifice’s measuring holes.

Check

the process piping between the steam drum and the water level

transmitter. Condensate has to accumulate in the tubing before the

transmitter can work properly again.

Draining the level

transmitter that often wouldn’t be necessary if you have

stainless steel tubing between the boiler drum and the level

transmitter.

N.B. the feedwater flow controller has to be in manual mode during these procedures.

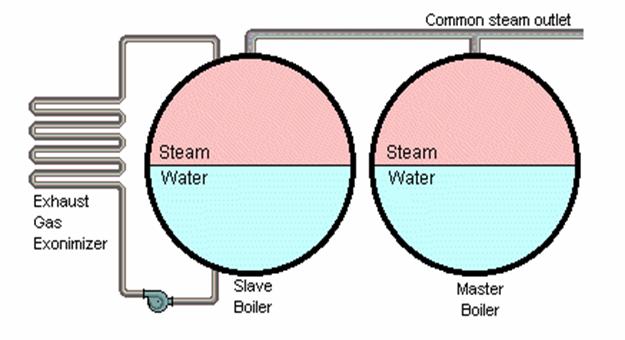

Keeping

a slave boiler pressurized.

In a two-boiler system it’s

often a problem to keep the slave boiler at operation pressure when

the steam demand is low. This problem does not appear when the vessel

is loading or unloading in a harbor since those operations normally

need both boilers. On the other hand, when the ship is at sea and

only one oil-fired boiler is used then the slave boiler tends to cool

down far below the required stand by conditions.

Different methods

have been used to solve this problem. Installing steam heating coils

in the bottom of the boiler is one method and a sophisticated

start-and-stop method for the slave boiler’s burner to keep the

pressure at desired level is an other.

These installations will be

unnecessary if you happened to have an exhaust gas economizer.

Just

connect the exhaust gas economizer to the slave boiler instead of the

master boiler. This operation method will guaranty normal operation

pressure on both boilers all the time at sea. The method has been

used in many ships and the chief engineers are satisfied with the

result.

A

colorless fuming liquid, N2H4, derived from diazoacetic acid: used as

a reducing agent in organic synthesis and as a fuel in jet

engines.

Used in boiler feed water treatment, to reduce oxygen in

the system, the normal level of hydrazine reserve to be maintained in

the water is between 0.1 and 0.3 ppm. The chemical reaction with

oxygen can be expressed as: N2H4 + O2 ==> 2H2O + N2

Excess

hydrazine, in a boiler, breaks down to produce ammonia that has

beneficial effects in raising the pH of the steam/condensate system

and thus affords some protection to the system by neutralizing any

carbon dioxide.

The reaction can occur in two ways:

3N2H4 ==> 4NH3

+ N2

2N2H4 ==> 2NH3 + N2 + H2

Hydrazine should be handled with care since it is allergenic and carcinogenic to humans.

Marine boiler plants require adequate control systems to raise steam, maintain design conditions for steady steaming, secure the boiler units and detect promptly malfunctions and failures. The automatic control arrangement on a shipboard boiler is divided into two parts:

Safety system that controls that all values are within the predetermined limits and give automatic alarm if some of them are not, and also initiate an automatic burner trip in case of a dangerous situation.

Continuously control of the different parameters for water level control, steam pressure control, fuel oil pressure control, fuel oil temperature control, blowdown control, superheat temperature control etc.

The combustion control system maintains constant steam pressure by controlling the flow of air and oil to the burner. The more advanced combustion controls transmit the air and oil loading simultaneously but with a slight lag between air and oil, so that with an increased boiler load, the air will lead the oil, and on a decrease in the boiler load the oil will lead the air. Such an arrangement makes it possible to minimize the emission of smoke during maneuvering. All the classification societies have special requirement for marine applications due to the environment and the fact that one can't escape from an accident nor get service when the ship is sailing at sea. Things just have to work.

An

easy way to find out if your boiler control system lights up the

first burner safely.

Safely

shut off the fuel supply to the burner before the test.

1. Power up the boiler control system.

2. Start the burner.

3. Start a stopwatch when the combustion air damper has reached its maximum position.

4.

Stop the stopwatch when the combustion air damper begins to close

again, and note the purge time. The air in the furnace should be

changed at least five times during the prepurge period.

Find the

furnace volume and the fan capacity from the documentation’s

and calculate the purge time needed. The time must never be less than

fifteen seconds even if your calculation says so.

5. Start the stopwatch again when the automatic fuel oil shutoff valves open.

6.

Stop the stopwatch when the fuel oil shutoff valves close and you get

a flame failure or misfiring alarm, and note the trail-for-ignition

time. If the time you get is more than fifteen seconds, then you must

not ignite the burner ever, until the time has been adjusted. Five

seconds is a relevant trail-for-ignition time, but different

classification societies specify different maximum time. Get the

correct maximum time from the rules of the actual classification

society.

N.B. This shut off delay is only allowed during

trail-for-ignition. When you got at flame failure during normal

firing the fuel oil valves must shut off instantly.

Some further checks to improve the safety

1. The fuel oil flow during light-up must not exceed 20% of the full load flow, but in burners with limited turndown ratio the burners minimum load has to be accepted.

2. A corrupt flow transmitter signal may cause sever problems therefore:

· When purging the furnace whit air prior to light-up the position of the combustion air damper should be confirmed by means of a limit switch rather than relying only on the air flow transmitter's signal.

· At burner light-up the position of the fuel oil control valve and the combustion air damper should be confirmed by means of limit switches rather than relying only on the flow transmitters' signals. You should of course use the transmitters' signals, but they ought to be confirmed to be reasonable by means of limit switches.

3. Direct the light from a flashlight onto the flame scanner sensors, when the burner is off, to confirm that the auto-check-function works correctly and you get an alarm. If you get any other action, such as opening of the fuel valves, then your system needs a thorough improvement.

4. Using the igniter during the post-purge of the last burner's lance (or a single burner's lance) has some disadvantages. Upon reset of the system, after a flame failure, the igniter will start firing before the furnace has been properly purged with air, which will cause impending risk of furnace explosions. Consider the following:

· A well-tried method is to purge the fuel line and the burner-lance slowly to let the fuel continue to burn, without igniter support, until the lance is empty.

· Not purging the burner-lance at all is an other method, but it requires a stand-by heating of the tubing and the lance to keep the fuel sufficiently heated to be floating.

· What ever you do, secure that the igniter not under any circumstances starts before the furnace has been properly purged with air.

Back to the question in the headline, is an automatic controlled boiler an explosion risk?

|

In automatic mode and properly adjusted: |

No |

|

In manual mode, skillfully operated: |

No |

|

In automatic mode and not properly adjusted: |

Yes |

|

In manual mode, not skillfully operated: |

Yes |

How

to make a control loop fail-safe

Example: A simple control loop

for pressure control of a steam boiler with one oil fired burner.

Control Valve An electro-pneumatic Control Valve for the fuel oil to the burner should close upon control air failure as well as missing current signal.

Pressure Transmitter The Pressure transmitter has normally a direct output signal, that is, the signal increases on raising pressure. Normally the current signal will never be lower than 4 mA, but if it does, the Controller should immediately close the burners fuel oil control valve

Controller Any internal fault in the Controller must initiate closing of the fuel oil control valve.

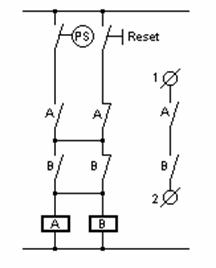

How to make a relay fail-safe

A

relay is almost fail-safe since it is very likely to brake the

circuit when it is malfunctioning. However, using two relays will

increase the reliability considerably. This can be done in different

ways. One method is to wire the relays, A and B, as shown on the

picture.

The system cannot be reset unless the pressure switch

(PS) makes and both relays work correctly, but the circuit between

terminal 1 and 2 will break when PS breaks even if only one relay

works rightly.

How

to make a computerized control system fail-safe

An output from a

computer will become either high or low when it fails. There are some

methods using the computer to check its own outputs. Feeding back an

output’s signal to an input will enable the computer to check

if the output is what it is supposed to be, but the system as a whole

will not be fail-safe. The CPU or any other vital part might break

down and then the check of the outputs is out of order.

The only

way to make a computer system fail-safe is to use an other computer

to check all the functions. It is, of course, possible to check all

the functions by means of hard wiring and relays, but who wants to do

that?

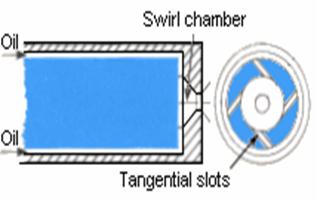

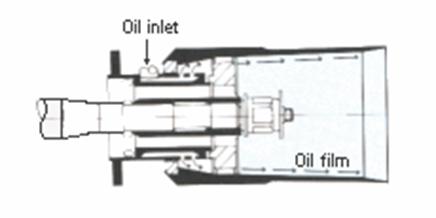

Pressure jet atomizer

The

pressure jet atomizer utilizes the supply pressure energy to atomize

the fuel into a spray of finely dispersed droplets. Provided adequate

fuel pressure is used, extremely good combustion results can be

achieved.

The fuel oil is fed into the swirl chamber by means of

the tangential ports in the main atomizer body. An air core is set up

due to the vortex formed in the swirl chamber; this results in the

fuel leaving the final orifice as a thin annular film. This film of

fuel has angular as well as axial velocity causing the fuel to

develop into a hollow con as it discharges from the orifice.

This

type of atomizer has a poor turn down ratio. A small drop in

atomizing pressure will result in a dramatic reduction in combustion

performance. Two or three nozzles are sometimes fitted to achieve

turn down, one in use on low fire, two on medium fire and three for

full rate firing. A variation of the pressure jet atomizer is spill

return or recirculating burner. The problems with this type of burner

are that the atomizer has an increasing cone angle of the issuing

spray as the burner is turned down with impingement on the furnace

walls, being made possible and the additional problem of how to

dispose of the returned hot oil if the burner has been running for

prolonged periods on low fire.

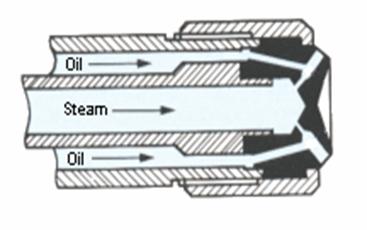

External mix steam atomizer or Steam-assisted pressure jet atomizer

The

steam-assisted pressure jet atomizer is designed to make full use of

pressure jet atomization at high outputs and full use of blast

atomization at low outputs.

The atomizer consists of a

conventional simplex type of pressure jet tip, around which is

provided steam supply passage. Steam issues through an annular gap

after being provided with the correct degree of swirl to ensure that

the steam-exit angle matches the oil-spray cone angle. The

steam-supply pressure remains constant throughout the complete

turndown range of the burner. No mixing of fuel oil and steam occurs

within the burner-gun and hence oil o~tput is unaffected by slight

variations in the steam pressure.

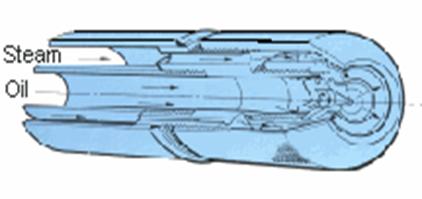

Internal mix steam atomizer

The

burner lance consists of two concentric tubes, a one-piece nozzle and

a sealing nut. The media supplies are arranged so that the steam is

supplied down the center tube and the fuel oil through the outer

tube. Consequently, the steam space is completely isolated from the

oil space.

The steam atomizer consists of an atomizer body that

has a number of discharge nozzles arranged on a pitch circle in such

a way that each oil bore meets a corresponding steam bore in a point

of intersection. Oil and steam (air) mix internally forming an

emulsion of oil and steam at high pressure. The expansion of this

mixture as it issues from the final orifice produces a spray of

finely atomized oil.

Oil burners with steam atomizing are

tolerant to viscosity changes. In addition to this advantage, the

steam atomized oil burners have better turn down, do not require high

fuel oil pump pressures, and are frugal in the use of steam.

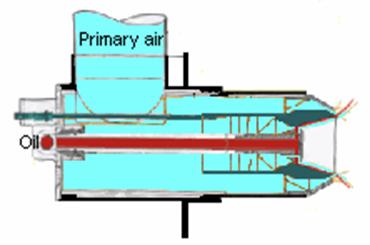

Rotary cup atomizer

The

rotary cup is driven at high speed (about 5000 RPM) by an electric

motor via a heavy-duty belt drive. The fuel oil flows at low pressure

into the conical spinning cup where it distributes uniformly on the

inner surface and throws off the cup rim as a very fine oil film. A

primary air fan discharges the primary air concentrically around the

cup, strikes the oil film at high velocity and atomizing it into tiny

droplets.The rotary cup burner finds considerable use on packaged

shell type boilers. These burners have good turn down ratio and they

are rather insensitive to pollutants in the fuel oil.

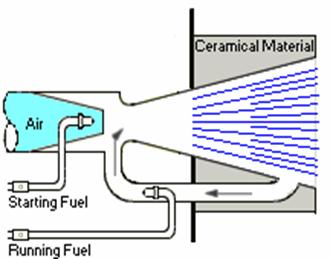

Low pressure air atomizer

The

principle is similar to that of the rotary-cup-atomizer, but the fuel

is forced to rotate in a fixed cup by means of a forcefully rotating

primary airflow. Their general construction makes them suitable for

firing into chambers of hot brickwork, avoiding all the hazards of

back radiation to oil burners of more delicate construction. Low

pressure air atomizers imply air pressure up to 100 mbar (40 ins.

WG.).

Blue flame burner

A

few words about firing sludge in a boiler furnace.

Is

the sludge a waste just to get rid of or is it a valuable fuel?

Well,

it’s both. It’s waste oil that you want to get rid of,

but it contains energy that you ought to utilize.

The waste oil

has to be conditioned to form a smooth emulsion with between 20% and

30% of water. Circulating the content of the sludge service tank with

a large pump and, if necessary, add some water will be a useful

method. The percentage of water might be measured by means of a

capacitive electrode in the pipe downstream the circulation pump. The

measuring method has some disadvantages, but it works.

The

temperature of the emulsion should be adjusted to achieve the

viscosity recommended by the burner maker, but it mustn't exceed the

boiling point of the water.

It’s normally difficult to

fire pure sludge; it has to be mixed with normal fuel oil. The

sludge/fuel oil ratio depends on the sludge quality. With a really

poor sludge you can only fire about 10% sludge. With a better,

well-mixed sludge the ratio could be much higher, but the burner has

to be continuously supervised, since it’s very difficult to get

a homogeneous sludge-mixture and the air demand may change

suddenly.

There is no problem to fire sludge with this method.

The problem is that sludge contains a great portion of ash and

nonburnable sediments that accumulates on the surfaces of the

furnace.

Increased soot-cleaning is strongly advised.

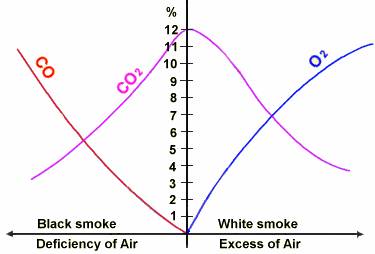

It is very easy to achieve a smokeless fire without any special equipment for supervision. On the other hand, to achieve a smokeless fire and economic combustion will be a bit harder. The air supply has to be slightly in excess of the theoretical requirements. That is, the combustion air flow is reduced almost to the smoke limit. A plant that never shows traces of smoke at the chimney is not burning the fuel efficiently.

There are four instruments that will help you to achieve the optimal combustion:

1. Smoke Density Monitor. High smoke density indicates uneconomical combustion and it might also cause penalty from the environmental protecting authorities.

2. O2 - Analyzer. High O2 content indicates heating of unnecessary high quantity of combustion air.

3. CO - Analyzer. High CO content indicates unburned hydrocarbons. This is not only uneconomical, the CO is also harmful to mans health. Besides, mixed with air, CO might be an explosion risk.

4. CO2 - Analyzer. Low CO2 content indicates poor combustion, but it doesn’t tell if more or less air is required.

The

most important instrument, the Smoke Density Monitor, happened to be

the cheapest of them and you can’t do without it if you are

trying to optimize the combustion of your burners.

The equipment

is very simple. A light beam is sent across the flue duct, from a

light emitter to a light receiver. An electronic unit monitors the

opacity. It indicates 0% if there is no black smoke present and 100%

if the light beam is totally absorbed by the smoke. An alarm

activates if the smoke density exceeds the preset limit.

Some advises:

The smoke density meters light emitter and light receiver are normally scavenged by sealing air to keep them free from soot. Therefore it would be vise to install these units higher up in the flue duct than the O2-analyzer to prevent the measured O2 value from being influenced by the smoke density meters sealing air flow.

Check and clean the glasses of the smoke density meters light emitter and the light receiver regularly.

The smoke density alarm should be overridden during the burners start and stop sequences, since the opacity normally increases before the flame has stabilized.

Never adjust the O2 content all the way down to zero unless you have facilities to check the CO content.

It might be worthwhile to spend a few minutes studying the diagram below.

|

|

Maximal velocity in pipes |

||||||||

|

|

Water |

m/s |

ft/s |

||||||

|

|

Tap water (low noise) |

0.5 - 0.7 |

1.6 -8.2 |

||||||

|

|

Tap water |

1.0 - 2.5 |

3.3 - 8.2 |

||||||

|

|

Cooling water |

1.5 - 2.5 |

4.9 - 8.2 |

||||||

|

|

Boiler feed water. suction |

0.5 - 1.0 |

1.6 - 3.3 |

||||||

|

|

Boiler feed water. discharge |

1.5 - 2.5 |

4.9 - 8.2 |

||||||

|

|

Condensate |

1.0 - 2.0 |

3.3 - 6.5 |

||||||

|

|

Heating circulation |

1.0 - 3.0 |

3.3 - 9.8 |

||||||

|

|

Lower velocity in thin lines. higher in thick lines. The pressure drop normally calculates separately for longer lines with several separate bend-resistance´s. |

||||||||

|

|

Steam |

m/s |

ft/s |

||||||

|

|

Saturated Steam. high pressure |

25 - 40 |

82 - 131 |

||||||

|

|

Saturated Steam. in special cases |

- 60 |

- 197 |

||||||

|

|

Saturated Steam. medium and low pressure |

30-40 |

99 - 131 |

||||||

|

|

Saturated Steam. at peak load |

- 50 |

- 164 |

||||||

|

|

Steam / Water emulsion |

- 25 |

- 82 |

||||||

|

|

The pressure drop normally calculates separately for longer lines with several separate bend-resistance's. |

||||||||

|

|

Oil |

m/s |

ft/s |

||||||

|

|

Suction lines for pumps |

- 0.5 |

-1.6 |

||||||

|

|

Suction lines for pump (low pressure) |

0.1 - 0.2 |

0.3 - 0.65 |

||||||

|

|

Discharge line for booster pump |

1.0 - 2.0 |

3.3 - 6.5 |

||||||

|

|

Discharge line for burner pump |

- 1.0 |

- 3.3 |

||||||

|

|

Air |

m/s |

ft/s |

||||||

|

|

Combustion air ducts |

12 - 20 |

40 - 66 |

||||||

|

|

Air inlet to boiler room |

1 - 3 |

3.3 - 9.8 |

||||||

|

|

Warm air for house heating |

0.8 - 1.0 |

2.6 - 3.3 |

||||||

|

|

Vacuum cleaning pipe |

8 - 15 |

26 - 49 |

||||||

|

|

Compressed air pipe |

20 - 30 |

66 - 98 |

||||||

|

|

Ventilation ducts (hospitals) |

1.8 - 4 |

5.9 - 13 |

||||||

|

|

Ventilation ducts (office buildings) |

2.0 - 4.5 |

6.5 - 15 |

||||||

|

|

Exhaust gas |

m/s |

ft/s |

||||||

|

|

Ducts at minimum load |

- 4.0 |

- 13 |

||||||

|

|

Stack at minimum load |

- 5.0 |

- 16 |

||||||

|

|

Boiler with one-step burner (on - off) |

5.0 - 8.0 |

16 - 26 |

||||||

|

|

Boiler with two-step burner (high - low) |

10 - 15 |

31 - 49 |

||||||

|

|

Boiler with modulating burner (3:1) |

15 - 25 |

49 - 82 |

||||||

|

|

To keep the surface free from soot the velocity should always exceed |

3.0 - 4.0 |

9.8 - 13 |

||||||

|

It is recommended that the maximum inlet velocities applied to control valves should be as shown in the tables below. |

|

||||||||

|

Globe Valves Size |

Liquid |

Steam or Gas |

|

||||||

|

mm |

inch |

m/s |

ft/s |

m/s |

ft/s |

|

|||

|

15 - 25 |

1/2 - 1 |

9 |

30 |

120 |

400 |

|

|||

|

40 - 50 |

1 1/2 - 2 |

7.5 |

25 |

90 |

300 |

|

|||

|

65 - 100 |

2 1/2 - 4 |

6 |

20 |

75 |

250 |

|

|||

|

150 - 200 |

6 - 8 |

6 |

20 |

70 |

225 |

|

|||

|

250 - 400 |

10 - 16 |

4.5 |

15 |

55 |

175 |

|

|||

|

Angle Valves Size |

Liquid |

Steam or Gas |

|

||||||

|

mm |

inch |

m/s |

ft/s |

m/s |

ft/s |

|

|||

|

15 - 25 |

1/2 - 1 |

13.5 |

45 |

135 |

450 |

|

|||

|

40 - 50 |

1 1/2 - 2 |

12 |

40 |

105 |

350 |

|

|||

|

65 - 100 |

2 1/2 - 4 |

10.5 |

35 |

90 |

300 |

|

|||

|

150 - 200 |

6 - 8 |

9 |

30 |

85 |

275 |

|

|||

|

250 - 400 |

10 - 16 |

7.5 |

25 |

70 |

225 |

|

|||

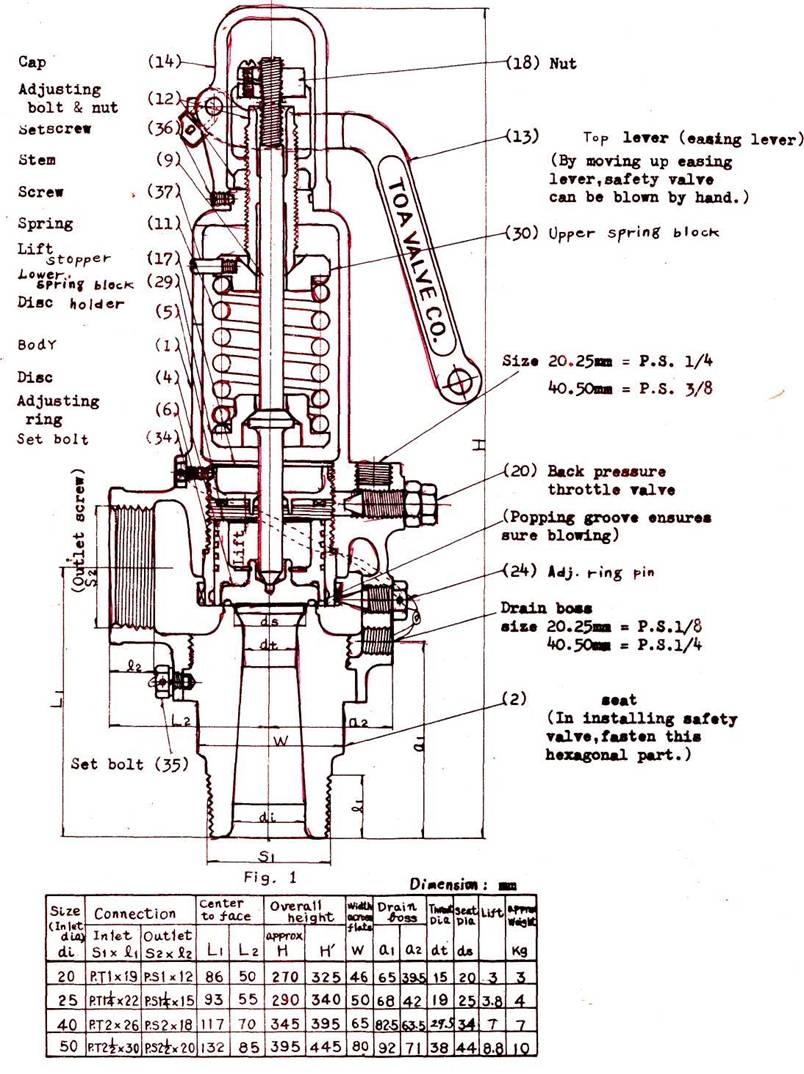

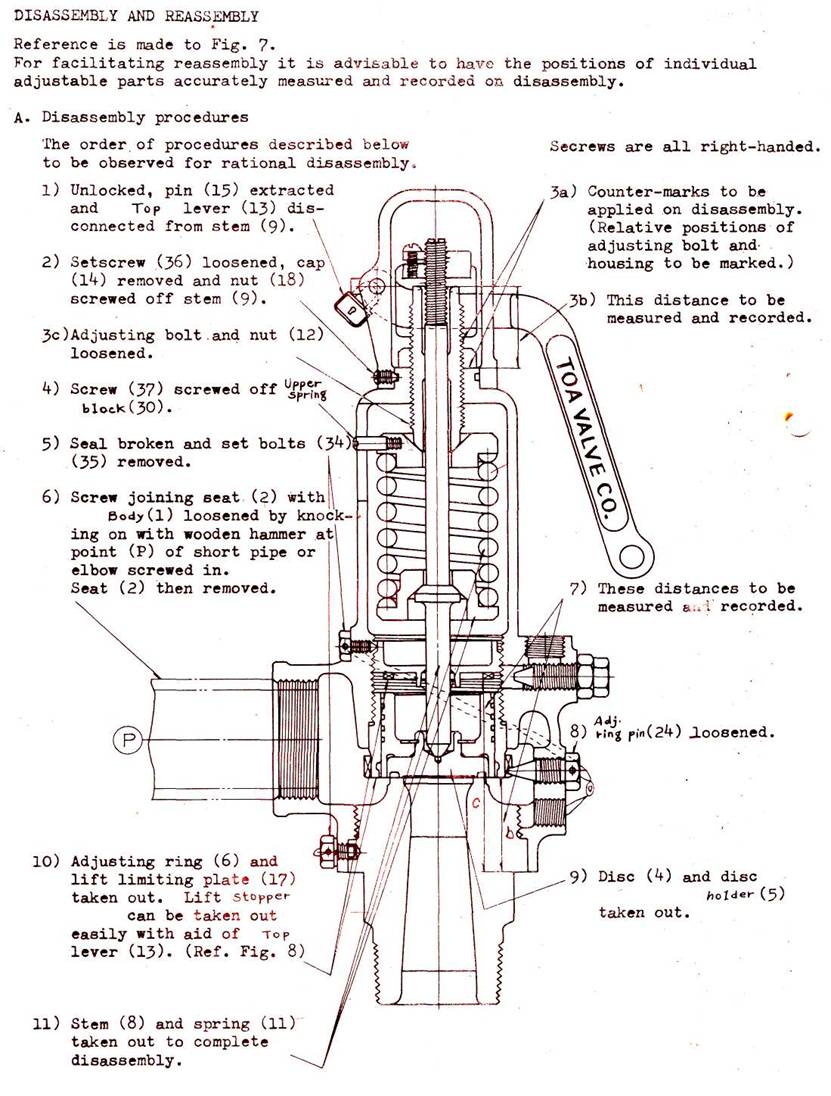

EXPLANATION OF OPERATION

This Type 1627 Full-Bore Safety Valve with its flat seat and piston type disc features its high relieving capacity.

A safety valve is required to blow off with utmost accuracy and sure-ness when the specified pressure ( mentioned on name plate) has been reached.

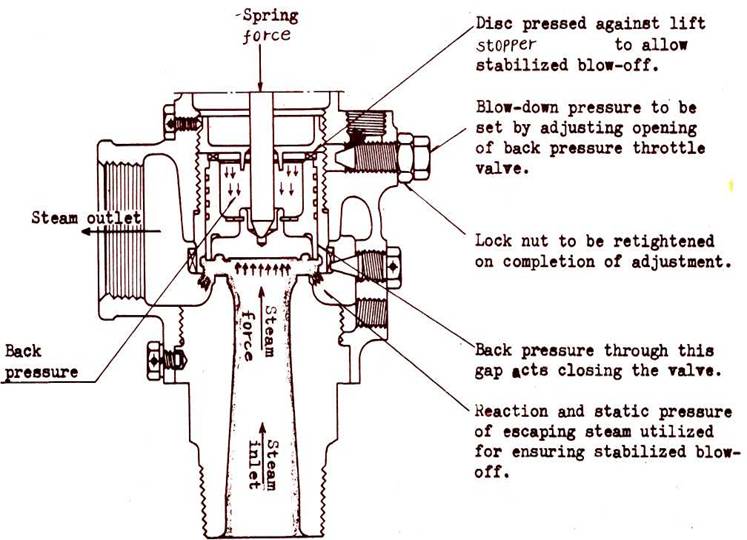

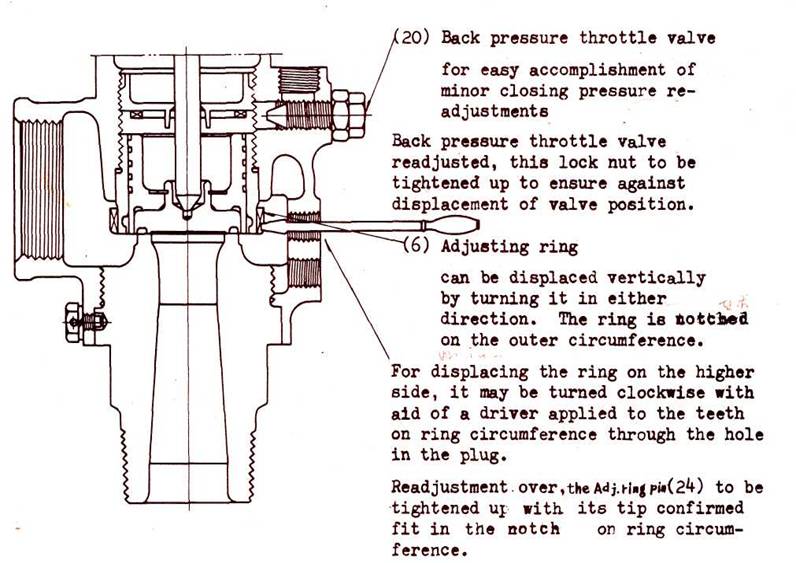

The relieving mechanism of this safety valve is characterized by the popping groove provided on the disc which produces an extra lift and also the adjusting ring for better utilization of the dynamic pressure produced by steam flow and hence the valve readily pops (opens quick and clear) once the specified blow-off pressure has been reached. The valve is also provided with a readily adjustable back pressure throttle valve which may be set to ensure secure closing of the valve after well-stabilized relieving of excess pressure. (Ref. Fig. 1 and 2.)

Fig. 2

Installation of exhaust pipe

With safety valves of full-bore type, proper arrangement of exhaust pipe is of particular importance. Care must be exercised to ensure secure fixing of the pipe to the valve. Standard piping plans recommended for our models are shown in Fig. 3 and Fig. k.

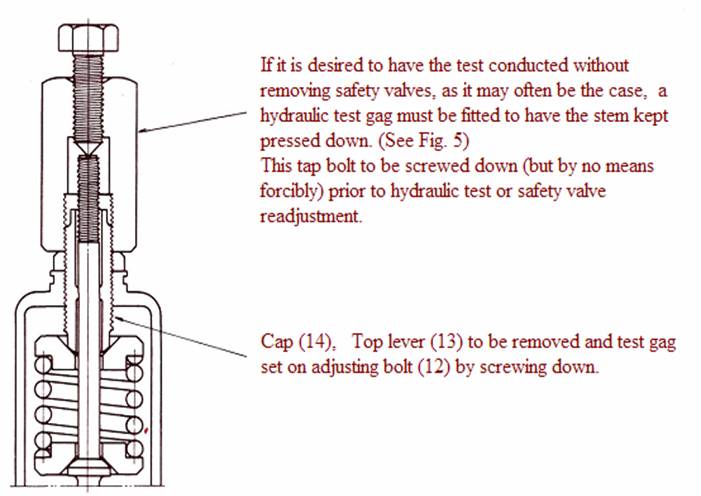

Hydraulic test gag

When a boiler is subjected to hydraulic test, it is always advisable to have the safety valves removed and blind covers fitted, for experience shows that the stem of the valve could be belt as it is kept pressed down during the test or dust or other foreign matters could find their way into the valve during the test to remain caught over seat face, thus interfering with proper functioning of the valve.

Since the disc of safety valve is pressed down under specific spring load corresponding to the specified blow-off or popping pressure, a very small application of force may be sufficient to have the valve locked against the hydraulic test pressure. It is always advisable to fasten the gag slightly after the test pressure has reached 80-90$ of the safety valve popping pressure and remove the gag after the test pressure has come down below the popping pressure.

In case more than two safety valves of different popping pressure settings are set on a boiler, the gag is to be used to lock the one with the lowest or lower poppint pressure.

Accidental blow-off of safety valve during adjustment can be hazardous and hence prior to adjustment it is essential to have the boiler pressure brought down to 80-90 % of the specified popping pressure and, if possible, the stem pressed down with test gag.

A. Adjustment of popping pressure

This is normally superfluous, for our valves are delivered precisely adjusted to the pressure specified on the name plate.

B. The data below may serve as guide for finding the number of turns to the adjusting bolt required for adjustment of popping pressure, to the desired level.

|

Safety valve size mm |

20 |

25 |

40 |

50 |

|

Adj. bolt 1\2 turn |

12.5 % |

10 % |

7.5 % |

5 % |

|

|| 1 turn |

25 % |

20 % |

15 % |

10 % |

It may be understood that the extent of such readjustment normally should not exceed +,- 10% of the value specified on the name plate. In case readjustment beyond this limit is considered essential, please consult us. (Major readjustments far beyond the said limit might call for replacement of the spring.)

C. Adjustment of closing pressure

With this safety valve, the extent of blow-down pressure (difference between poppint pressure and closing pressure) is adjusted a little broader than specified on the name plate but since the effective value is subject to change according to the way it is installed etc., adjustment in this respect has to be done on the spot. This, however, can be accomplished with ease by readjustment of the back pressure throttle valve, if the closing pressure of the valve not below 1.5 kg/cm2.

Fig. 6

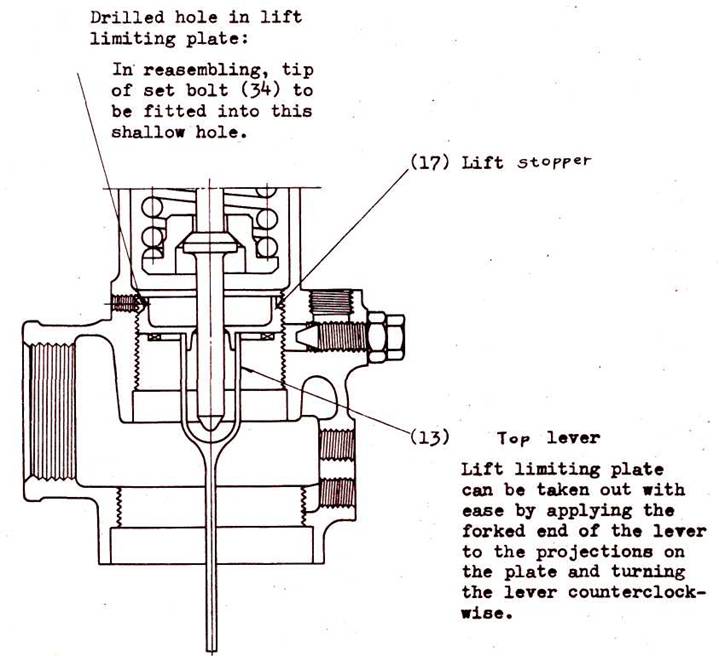

Fig, 7

Fig. 8

B. Reassembly

For reassembly may be simply reversed the procedures given for disassembly.

Prior to reassembly, all parts to be thoroughly cleaned and repaired. Stem tip, spring shoe, spring clamp and stem-adjusting bolt contact face to be coated with molybdenum disulfide or graphite (dissolved in mineral oil) for lubrication. Recorded positions of lift limiting plate, adjusting ring, adjusting bolt etc. to be carefully observed in reasembling.

5. LAPPING AND REPAIR

The disc and seat of this safety valve can be easily lapped on a lapping plate with use of a proper type of lapping compound. As lapping compound is to be chosen # 600 kneaded with purified rape oil ("shirashimeyu") to non-flowing consistency. Hints on lapping:

1. Both lapping plate and parts to be kept clean.

2. Excessive application of compound to be avoided.

3. Lapping to be performed with lapping plate or disc in an alternate turning motion and pressed on lightly.

4. Lapping plate be precisely finished and kept well repaired.

5. Lapping of disc against seat to be avoided.

Practically, this valve calls for no repair work beyond lapping on the part of users and should there be any parts calling for repair, our service department is to be commanded or such parts mailed to us.

WATER LEVEL GAUGE (REFLEX TYPE)

INSTRUCTION MANUAL

TYPE RZ .

1. This water level gauge (reflex type) is usually sent out from our factory in the following packages:

1) Water level gauge (with lower cap nut)

2) Upper cock, lower cock and drain cock

(The drain cock is set with the lower cock.)

3) Marine parts: Wires

Wire parts (shackles, wire courses and wire clips)

Handles (6 handles)

Handle stoppers (to be mounted to the cock flanges)

4) Spares : Water level gauge

Gauge glass (with gasket)

Sleeve packings

Gland packings

Copper sheet packings (for only the lower lead pipe)

5) Tool : Sleeve packing replacing tool

Water Tightness Test before Operation

When this instrument is mounted for a newly installed boiler or a boiler in shutdown, carry out the following water tightness test for the water level gauge including the gauge cocks at the time of the boiler starting test.

1) Open the drain cock and close the upper and lower cocks. First, check the gas tightness of the upper and lower cocks (especially the opening and closing elements).

2) Next, close the drain cock and open the upper and lower cocks. Make the tightness checks for the whole of the water level gauge and cocks.

3) If any leakage is found in the test, take the corrective actions.

Precautions for Operation

1) In the water level gauge come from factory, there is a balance kept between the bolt tightening force and the gas tightness of each part by the hydraulic test under the ordinary temperature. Therefore, when this instrument is installed to the boiler in operation and also when the pressure and temperature are raised from the ordinary conditions along with the boiler pressure increase, take care to avoid a rapid pressure and temperature application to the water level gauge.

2) In operation and in pressure raise, use caution to find out leakage. Give a tightening to the bolt and nut of the part where any leakage occurs. Also after the pressure is raised to the specified value, check for any leakage. Even if there is no leakage, give a slight tightening to each bolt of the water level gauge.

3) At the start-up of the boiler, repeat water blowing until clean water is recognized so that the good conditions for the water level gauge will be kept in the boiler system. During operation, except when the water is polluted, water blowing is not desirable so far as the water level is fluctuating.

4) When the boiler is in operation, always make a leakage check and give a tightening when necessary. Thus, parts consumption must be minimized.

Maintenance

Disassembly and Reassembly of Water Level Gauge

After the lapse of the service life, the prism surface of the reflex type gauge glass wears out and loses reflectivity and as a result the water level becomes invisible. As the gauge glass and sheet packings are damaged, it becomes impossible to stop leakage with tightening of the water level gauge bolts and nuts. In such a case, disassemble the water level gauge and replace the worn-out parts in the following procedure:

1) Detach the water level gauge from the upper and lower cocks. Disassemble the water level gauge preferably when it is still in hot condition (this will facilitate the removal of the packings).

2) Place the water level gauge on a working bench, loosen the bolts and nuts and remove the cover.

3) As the gauge glass is sticking to the level gauge body through packings, slightly rap the side with a wooden hammer to remove the glass. If this disassembly is made in an early time, the gauge glass may be re-used if only the packings are replaced. In such a case, therefore, remove the glass carefully not to break it.

4) Remove the packings carefully not to damage the gas tightness of the water level gauge body (the surface of contact with the packings) Clean out the residual dirts.

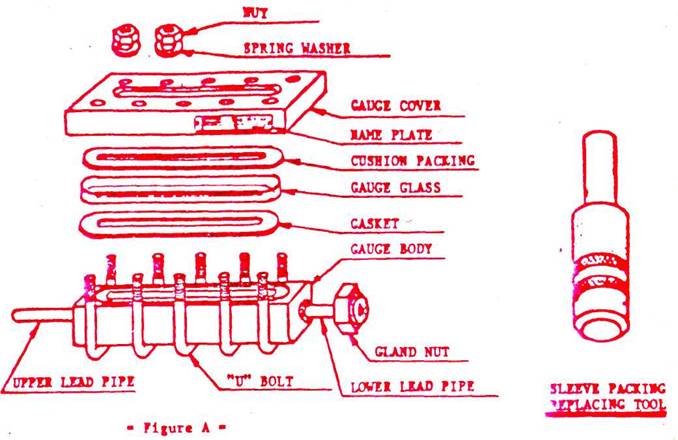

For the reassembly of the water level gauge, the above procedure is to be reversed. Follow the below instructions, referring to Figure A.

1) Attach the sheet packing to the gas tight surface of the water level gauge, using the following precautions:

a. Be sure to apply graphite paste to both sides of the sheet packing. It will facilitate the removal of the packing when gauge is disassembled.

b. As the sheet packing is hollowed out in the center part, it is likely to deform to narrow the cut-out area. When the packing is placed, care should be taken to keep the specified level gauge window area.

2) On the sheet packing, place the gauge glass with the prism side directed toward the liquid chamber.

3) Then, attach the cushion packing (asbestos plate) to the gauge cover and connect the gauge cover to the gauge glass. For setting the gauge cover, set the U bolt at the center to fix the cover temporarily and then set the other U bolts. As there is some allowance between the gauge glass and glass groove, carefully center the cover, gauge glass, and water level gauge body.

4) For tightening the bolts and nuts, follow the instructions.

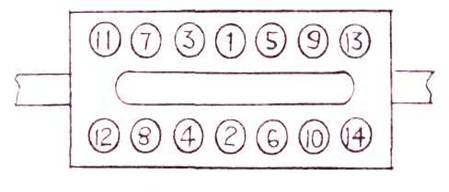

Tightening of Level Gauge Bolts and Nuts

Troubles such as gauge glass breakage and early-time leakage from the gauge glass in boiler operation are said to be, in most cases, caused by uneven tightening of bolts and nuts in reassembly of the level gauge, This means that the tightening of the bolts and nuts is the most important of various water level gauge maintenance works. Follow the below instructions:

1) Note that the water level gauge contains glass-ware and it belongs to delicate measuring instruments. Therefore, the tightening of the bolts and nuts must be made with the utmost care.

2) Set all the bolts and nuts hand-tight with an even torque. It is important to tighten them suitably to the extent that leakage can be prevented. Avoid uneven tightening.

3) Tightening is to be repeated several times with light hand motion as follows: For the first and second tightening, follow the numerical order given in the below sketch (the order from the center to the ends). For the third and fourth tightening, reverse the numerical order (i.e. from the ends to the center).

4) For the fifth and sixth tightening, again follow the numerical order (i.e. from the center to the ends).

5) In the last tightening, leave some tightening allowance by saving the hand force. If any leakage is found after the level gauge has been placed in service, give an additional tightening in the manner specified above.

6) In reassembly, too strong tightening can cause the gauge cover to bend or cause the gauge glass to break due to pressure application heat expansion in service.

7) In the last tightening, take case so that the tightening torque of the uppermost and lowermost bolts (4 bolts) will be kept at half the torque of the other intermediate bolts. The reason is that, as seen in the sketch, the uppermost and lowermost bolts (4 bolts) are located outside the gauge glass and, therefore, too strong tightening may cause the glass ends to break when the gauge is placed in service.

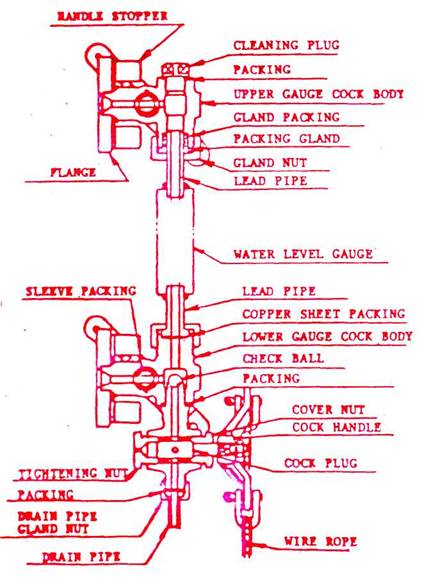

Additional Tightening and Replacement of Sleeve Packings

When the inside surfaces of the sleeve packings wear out with the cock plug opening and closing motion, leakage will occur from the cover nut or tightening nut (shown in Figure B). In such a case, give an additional tightening or replace the packings in accordance with the following instructions :

1) Tighten the tightening nut. The sleeve packings will be pressed toward the cock plug so as to recover the gas tightness and stop the leakage.

2) Every time when leakage is found, immediately give an additional tightening.

3) If such an additional tightening cannot stop the leakage, it indicates the loss of elastivity of the packings. Replace the sleeve packings, following the below procedure:

a. Remove the handle, tightening nut and cover nut.

b. Extract the cock plug toward the handle side. If it cannot be extracted by hand, apply an iron bar of about 10mm in length to the bottom of the cock plug and rap the bar to extract it out.

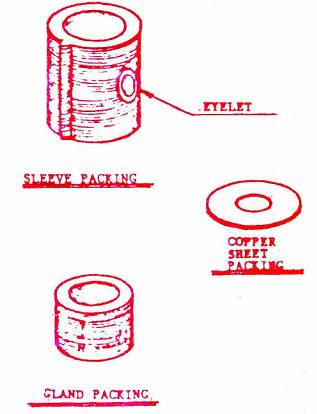

c. Then, apply the sleeve packing replacing tool (shown in Figure C) to the bottom of the packings. Rap out the packings toward the handle side.

d. For insertion of new sleeve packings, use the sleeve packing replacing tool and drive the packings into the cock body from the handle side.

e. Put the packing boss just in the groove of the cock body and insert the packings so that the periphery of the packings will be located at the position 11mm deep from the cock body periphery.

f. Mount the cover nut, and keep a clearance of about lmm between the cover nut and cock body.

g. Then, the cock plug is inserted. Apply the iron bar (indicated in Item b above) to the bottom of the cock and drive in.

h. Mount the cover nut and tightening nut.

i. Mount the handling.

j. Make an air (or water) passage test.

Replacement of Gland Packings

When the cap nut tightening cannot stop the leakage from the gauge cock and level gauge connecting part, replace the gland packings, following the below instructions:

1) Remove the upper and lower cap nuts and packing gland, and push up the gland packing.

2) Disconnect the lower lead pipe from the lower cock, and extract the upper lead pipe.

3) Smash the gland packings with use of a chisel, and remove them completely. Clean the stuffing box.

4) Drive in new gland packings to the position just lower than the specified position of the upper lead pipe. Then, plunge the upper lead pipe into the upper cock.

5) Gland packings must be replaced every time when the water level gauge is disassembled. However, copper packings can be re-used after they are annealed.

6) Then, carefully drive the gland packings into the stuffing box and mount the packing gland and upper cap nut.

7) Tighten the cap nuts in the order of the lower cap nut and upper cap nut.

Other Precautions

At periodical maintenance, disassemble the water level gauge and carry out the replacement of consumables and the cleaning of the gas (water) passage holes. Apply graphite paste to each threaded part before reassembly. Check the gas tight surface of the water level gauge for any distortion or erosion. When necessary, repair or replace them.