Cracks in boiler plants

This provides a brief description of the five most common categories of cracks in marine boiler plants and explains how to detect them and how best to avoid them.

Tube burst due to short-term overheating Creep cracks in a boiler end plate due to long-term overheating

Cracks in marine boilers

Next to corrosion and contamination, cracks are the most frequent cause of sudden damage and service interruptions in all types of boilers.

Cracks in boiler steel materials can be divided into five categories relating to the cause of the formation of cracks.

Bursting due to short-term overheating

Creep cracks due to long-term overheating

Corrosion fatigue and stress induced corrosion

Thermal shock cracks

Stress corrosion (caustic embrittlement)

Bursting due to short-term overheating

At severe but short-term overheating, a boiler tube is often heated to 800-1,000ºC before the tube blows up like a balloon and eventually bursts.

A brief overheating of pressurized boiler tubes might be due to lack of cooling of one or more tubes either at partial dry running of the boiler or because of blocking-up of the tube.

Creep cracks due to long-term overheating

While a short but severe overheating causes considerable deformation of the tube, a long-term overheating often causes less deformation limited to a minor area around the crack. A metallurgical examination of the material in the vicinity of the crack shows clear signs of creeping with development of voids in the grain boundaries and several parallel cracks.

Although it is suitable to divide overheating damage into short term and long-term overheating damage, damage types in categories between these extremes can occur. Often, minor short-term overheating will cause a crack to arise in a tube already weakened by long-term overheating.

Corrosion fatigue and stress induced corrosion

These two causes of cracks, often called corrosion fatigue only, represent the most frequent causes of cracks in boilers. While corrosion fatigue arises during simultaneous

influence of varying mechanical stresses and a corroding medium such as boiler water, stress-induced corrosion also takes place during stress-free periods, for instance during stand-still.

Simply put, stress-induced corrosion can be characterized as a corrosion-dominated crack formation, while corrosion fatigue is a more mechanically dominated fatigue.

The varying mechanical stresses are in most cases caused by fluctuating temperature loads of the boiler.

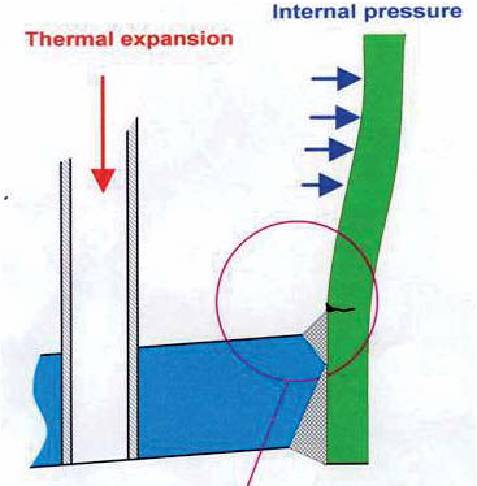

Many stresses result from the heat influence and the different expansion rates of the individual boiler parts between cold, partial load and full load conditions. Other stresses arise during start-up of a cold boiler plant and at variation of the boiler load and are due to the fact that it takes some time for the individual boiler parts to reach the temperature balance. While for instance the boiler tubes are very soon able to follow the temperature fluctuations, the heavy gauge upper and lower drums take much longer time to do so.

Other causes of mechanical stress in marine boilers might be vibrations transferred from the hull.

In connection with periods of stand-still and in boilers with boiler water containing too much oxygen, an oxygen-driven corrosion takes place in the actual crack, as a galvanic oxygen concentration element is formed between the crack and its surroundings.

Thermal shock cracks

Thermal shock cracks are originally a special type of corrosion fatigue or stress-induced corrosion caused by alternating heavy heating and cooling over a temperature span of

some hundred degrees.

At thermal stresses, the material makes the protecting magnetite layer break in narrow cracks in a more or less parallel arranged pattern.

Stress corrosion

Caustic embrittlement has been known in boilers long before anything was called stress corrosion.

The cracks appeared especially around the inevitable leaks at the riveted assemblies of the boilers.

As time passed, engineers learned to control the water treatment so that caustic embrittlement did not occur.

When introducing the fully welded boilers, everybody was convinced that the problem had been definitively solved, as boilers could now be made completely tight.

Nevertheless, corrosion damage arises now and then, also in fully welded boilers.

Stress corrosion is a characteristic type of crack formation arising in a material which at the same time is influenced by mechanical stresses and a corrosion-inducing environment.

In boiler plants, the caustic soda used for alkalizing the boiler water is usually the cause of most cases of stress corrosion. If the caustic soda concentration in the crack is as high as 20-30% NaOH or higher, the environment is conducive to causing cracks. Such concentrations might occur in a leakage where the boiler water evaporates and leaves the concentrated boiler salts.

An increased concentration of caustic soda in the boiler water might also occur in a heat-loaded gap, for instance between the tube and tube plate, or in a pore in a welding, often when the boiler is rather new and before the gap has been closed by boiler scale and magnetite.

Detecting boiler cracks

When comparing the results of a metallurgical examination with information about the construction and operation of a boiler plant, it is possible to identify the cause of the damage so that new incidents can be avoided. However, due to busy schedules, there is often no time for a thorough examination and the owner may opt for a temporary repair of the boiler.

Sometimes, the problem is solved by this action. In other cases, new and often more severe damage arises. Therefore, it is advisable to contact a boiler repair specialist to assist in the assessment and solving of the problem at hand.

Preventive measures

Cracks in boilers can most safely be avoided by means of an adequate water treatment programme which is suitable for the boiler in question and its particular operating conditions.

Furthermore, cracks can be prevented by observing that the permissible stress levels for boiler construction are not exceeded. This can be avoided by following the instructed firing up procedures and load change limitations of the individual boiler.