Amount of brine cooling surface :-

Brine pipes commonly of mild steel externally galvanised and painted, about 40mm bore.

Pipes are tested to 7 bar or 2.5x working pressure, whichever is higher.

It is usual to regulate the flow of brine by the return valve on the distribution and return

headers.

The supply of air circulation to any storage room will reduce the brine cooling surface required by as much as 50%.

For chilling chambers - 3m of chamber volume requires lm2 of pipe cooling surface without air circulation.

4.5m3 of chamber volume requires lm2 of pipe cooling surface if air circulated. For freezing chambers - 1.5m3 of chamber vol. Requires lm2 of pipe surface and 2.2m /Im if air circulated.

Due to corrosive action of brine, there is a possibility of hydrogen gas emission in the brine room and naked light should be avoided

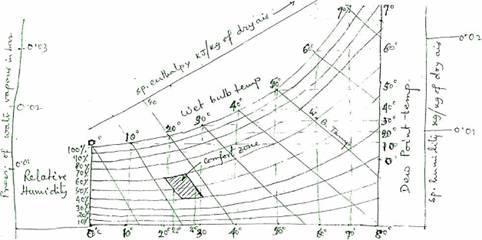

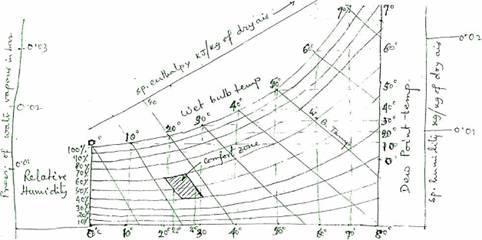

Absolute Humidity :- It is the mass of water vapour present per Kg of air in a given

volume.

Specific humidity :- It is the ratio of the mass of water vapour to the mass of dry air in a

given volume.

% Relative Humidity :- it is the percentage ratio of mass of water vapour per m3 of air

to

the mass of

water vapour per m3 of saturated air at that temperature.

It is also the ratio of partial pressure of the actual air to the

partial pressure of the air if it was saturated at the same

temperature, %RH = m\ms_x

100 = p\ps

x

100

Dew point: - Dewpoint is that temp, at which the air can hold maximum water vapour i.e. fully saturated with water vapour having 100% relative humidity. Below this temp, at constant pressure, the water vapour starts condensing. As the amount of water vapour in air varies, the partial, pressure varies and the dew point also varies.