OIL CONTENT MONITORING

Conductivity, Capacitance, Acoustic Attenuation, Sonic Impedance are all poor with respect to sensitivity and would usually be used only to detect oil/water interfaces (as in oil/water separator).

1.

VISIBLE LIGHT ABSORPTION - A sample of discharge water from the oily water separator is

passed through a sampling chamber, and oil content is monitored by

a strong, light shining directly through it and on to a photo-cell. Light

reaching the cell decreases with increasing oil content in the water. The

effect of this light on the photocell is compared with that of the direct light

on the reference cell to other side of the lamp and the difference can be

measured and calibrated to show oil content. The accumulation of any oily

deposit on the inside of the glass

required to be cleaned regularly to avoid false reading.

2.

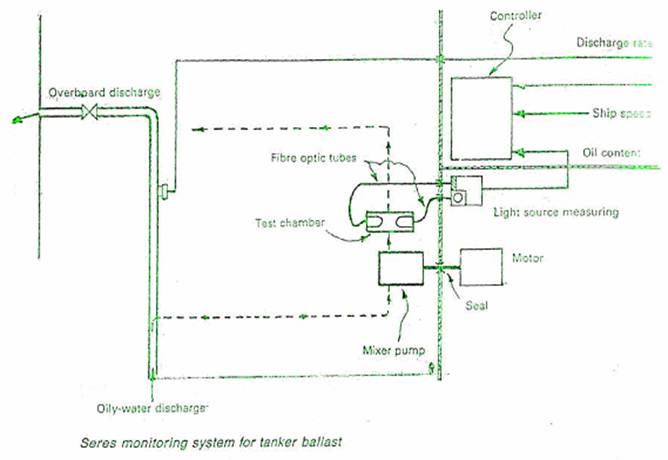

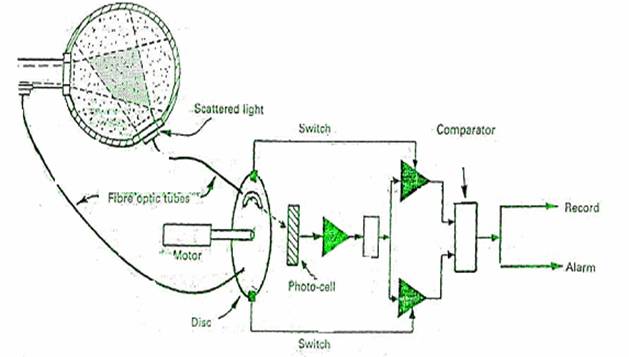

VISIBLE LIGHT SCATTERING - In this method a sampling pump directs the output from oil/water

separator through a special chamber in which light scattered by the oil droplet

is measured and compared with the source light. Light reflected or scattered by

any oil particles in the flow, illuminates the scattered light window.

If a light beam is projected through a test cell containing sample water with well-homogenized droplets, part of the light passing through the cell will be scattered. The intensity of light picked up by a photocell at the end of a straight path through the cell will be reduced, whereas the intensity of scattered light sensed by a photocell mounted at an angle to the original path will increase. Fibre optic tubes are used in the device to convey light from direct source and from the scattered light window to the photocell. The motor-driven rotating disc with its slot, lets each light shine alternately on the photo-cell and also by means of switches at the periphery, causes the signals to be passed independently to a comparator device, which records the oil content as well as gives an alarm when the oil content reaches close to maximum limit (15 ppm).

3. INFRA - RED ABSORPTION -

Infra - red light absorption is a promising method as most oils

absorb in the 3 .4jim wavelength. The variation in absorption rates between

heavy oils through to the light diesels is only approximate!/ 10%. However

water also has a strong absorption at the same wavelength and this makes

detectors using this technique complex.

The latest view is that, it would be useful

if the oil was extracted from the water with a suitable solvent, the solvent

having no absorption of the infraned wavelength. However, this would not allow

a speedy response

Sample water is passed through a homogenizer

and subjected to infra - red light whereas oil - free reference water of

relevant quality is continuously sent to the comparator unit. The infra-red

absorption by the oily water and by oil-free water are then measured. The difference of signal caused by absorption of oil

is calibrate for oil content.

4. ULTRA - VIOLET ABSORPTION -

Ultraviolet absorption does not encounter

the water absorption problem, as it use a wavelength of 0.254 mm but the

requirement, for the opto - electronics to detect small changes in a high light

level, limits the low range capability.

Principle used is that of Ultra - violet

florescence. This is the phenomenon of the emission of light from a molecule

which has absorbed light. The fluorescence efficiency of the oil is based on

the phenomenon that it is the molecules of 'unsaturated' hydrocarbons become

excited when illuminated with ultra - violet light of a certain wavelength and

will then radiate light in the visible spectrum. Different oils contain

different amounts of unsaturated hydrocarbons, so that the instrument must be

calibrated each time for the type of oil being monitored.

For a given oil in water concentration, the instrument response

depends on (a) the particle size and (b) the fluroscence efficiency of the oil.

The effect of particle size is minimised by the sample conditioning unit which

reduces the oil particles to a fairly uniform size.