CARGO PUMPS

MIXED FLOW PUMPS:

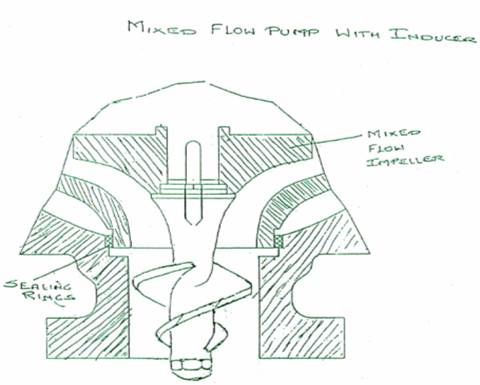

It operates partly as centrifugal and partly as axial flow pump. The impeller consists of a conical hub with blades shaped so that the fluid flow into the impellers is axial but flow through has an increasing radial component. At exit the flow is part radial part axiai.

Leaving the impeller, the fluid is diffused (velocity reduced, pressure increased) in fixed guide vanes, which redirect the flow to, the axial direction as the fluid leaves the pump casing.

An advantage of this configuration is that the axial discharge offers high flow rates and allows an easy arrangement for multi - staging which gives high discharge pressure. The efficiency of these pumps can be very high.

Frequently these pumps are used for cargo duties handling LPG,LNG and other volatile liquid cargoes. In this application they are usually fitted with scroll type Inducers, which enhance the suction characteristics of the pump. This reduces the N.RS.H required for a given discharge rate. The inducers are arranged, so that the pumps operates "Super Cavitating". The vapour bubbles formed in the inducer collapse in the region between the inducer and the eye of the first stage impeller.

Chemical, LPG or multi - product tankers uses separate pumps sited in side the tank. Pumps are driven through line shafting coupled to hydraulic motors'on deck, are generally deep well pumps, single or multi - stage with radial or mixed - flow impellers respectively.

SUBMERGED CARGO PUMP:

The pump drive is either electric or hydraulic, usually electric as there is some difficulty in obtaining a hydraulic fluid that can perform at the low cargo temperatures encountered. Additionally the use of hydraulic driven submerged pump requires that the hydraulic motor pipes to be triple cased to avoid the possibility of leaks containing the cargo. The motor and pump sit at the bottom of a trunk, the trunk forming the discharge riser to the-deck.

The submerged electric motor driven pump rests on a spring cartridge which closes when the pump is raised and seals off the tank from the column. Both pump and motor lubricated and cooled by the cargo passing over them. Submersible pumps eliminate line shaft bearings and gland problems but expensive problems could occur due to hydraulic fluid jeakage into the cargo and vice - versa. Guides are fitted in the trunk so the pump can be with drawn for servicing.

DISADVANTAGES -

a) A check for free movement of the pump can not be made prior to starting.

b) Due to the hazardous conditions of operation both pump and motor are of special low temperature gas tight construction.

c) Cables require special mineral-insulation.

d) External junction boxes have to be explosion proof and must be packed to prevent gas transit along the conduit.

e) As the liquid cargoes are mixed with their boil - off gases, the pumps would probably be fitted with inducers.

f) Electric submerged pumps would not be fitted for cargoes containing ammonia, due to the effect of this fluid on copper and its alloys.

pumps :

This pumps are fitted as separate pump to each cargo tank. The motor, which can be ether electric or hydraulic, is mounted outside the deckhatch.

The pump end is submerged at the tank bottom, the connection between motor and pump is by a long drive shaft.

The trunk that forms the housing for the shaft is also the cargo riser for discharge to the deck. This type of pump is suitable for most chemicals, including LPG and LNG. They would normally be fitted at the bottom of a well to assist in the complete removal of the required.

DISADVANTAGES -

a) Misalignment of the long drive shaft due to variation in ship's hog and sag and also due to temperature changes.

b) The shaft is supported by guides in the trunking, the guide bearings are lubricated ■ by the cargo.

c) The shaft where shaft enters the riser trunking requires special attention.

ADVANTAGES -

The main advantages of this arrangement is that free rotation can be checked prior to operation. The prime - mover can also be serviced if necessary.