GEAR PUMP

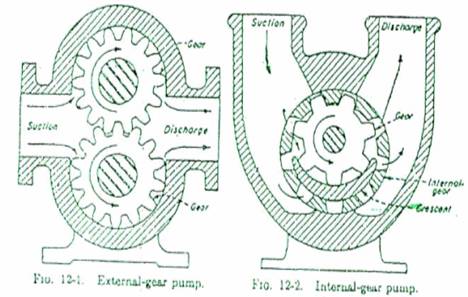

Gear pumps are positive displacement pumps used for diesel engine bearing lubrication and gearbox lubrication which are independently drives for large slow speed engines and stand - by duties but usually shaft driven for medium and high speed engines. Also used for fuel and oil transfer, boiler cumbustion systems and other duties.

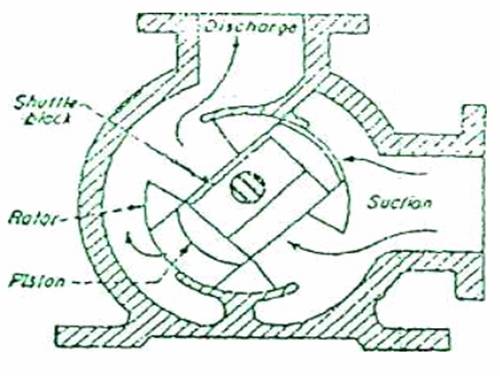

Fig. 12-8. Shuttle-block pump.

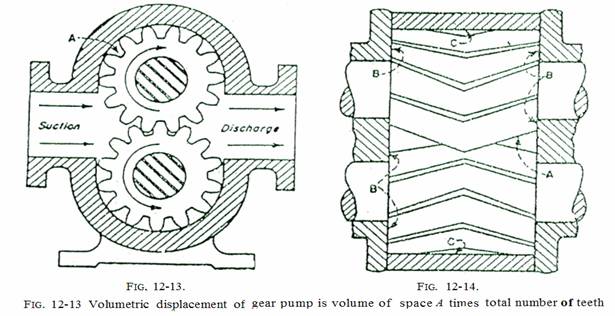

The simple gear pump has rotors and shafts which are integrally forged of nitralloy steel. They are hardened all over and ground finished after hardening. Closed grained grey cast iron is used for the casing and bearing housing. The shaft is supported in white metal bearings but needle roller bearings are an alternative. Lubrication is provided by the oil passing through, the liquid being pumped, is forced out after being carried around between gear teeth and housing, as the teeth mesh together. It is certain that the centrifugal effect contributes to the pumping action. There is no side thrust with straight gear teeth.

Side thrust is produced in case of single helical gears. To gain the benefit of using helical gears, a double helical is necessary and used in large slow speed engine lubrication system .Spring loaded relief valves are usually fitted and may be of adjustable calibrated type to facilitate control of delivery pressure. Capacity increases with the speed as well as the power input increase. Frictional power loss increases with viscosity and speed.

SLIP:

Slip or slippage is the quantity of liquid that escapes or leaks from the discharge back to the suction through the normal clearance spaces between the rotating elements and between elements and casing under operating pressure conditions.