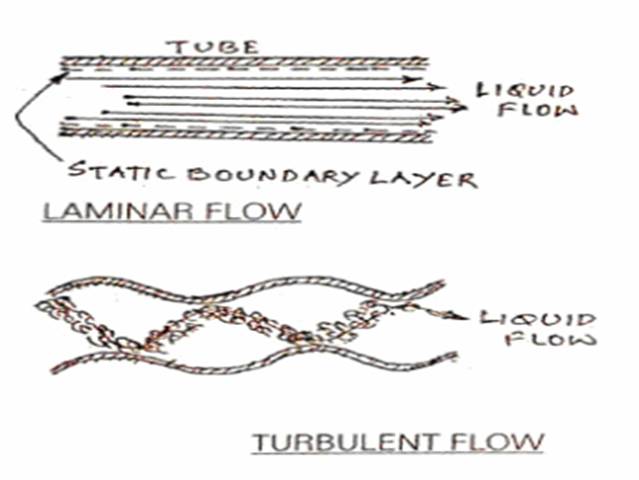

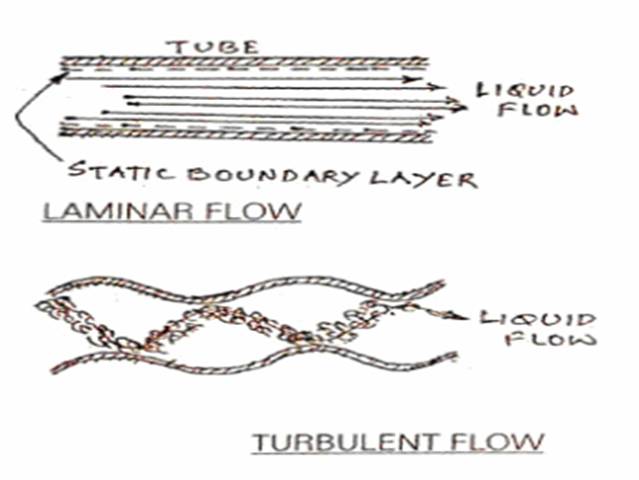

STREAMLINE AND TURBULENT FLOW:-

In streamline or laminal flow, fluid velocity variation is approximately parabolic in nature, being a maximum at the centre of the tube and zero where the fluid is in contact with the tube surface.^ This static boundary layer of fluid which adheres to the metal at the tube surface acts as a heat barrier and obstructs the heat transfer to a certain extent.

In plate type heat exchangers, the surface of the plates are corrugated to give strength and additional heat transfer surface. This gives addition support, allows pressure to be increased and plate thickness to be reduced. Here the fluid flow is turbulent in nature, which as opposed to smooth flow, causes-more of the liquid passing between the plates to come in contact with them and breaks up the boundary layer thus enhancing heat transfer.

Whether the flow is streamline or turbulent depends upon certain factors which are summed up by Reynold's number

Reynold's Number == Velocity of fluid flow x pipe diameter \ Kinematic viscosity

If the number is less than 2000, the flow is streamline. If the number is more than 2500, the flow is turbulent.

for efficient heal transfer, turbulent flow is best, but erosion of metal surface is greatest which must be taken care of by selection of proper wear resistant material.

Effect of heat transfer Co - efficient - the rate of heat transfer (Q) depends on the heat transfer coefficients of the fluids on the two sides of the wall surface (h), the surface area of the heat transfer wall (A) and the logarithmic mean temperature difference at the inlet and outlet of the heat exchanger.

Under normal operating conditions, water flowing over a surface gives a relatively high co-efficient of heat transfer, as does condensing steam, whereas oil provides a considerably lower value. Air is also a poor heat transfer fluid and it is quite usual to modify the effect of this by adding extended surface (fins) on the side of the wall in contact with air.