ENGINEERING METALLURGY

PHYSICAL PROPERTIES OF METALS

a) All metals (except mercury) are solids at normal temperatures. Non-metals include gases, a liquid (bromine) and solids.

b) Metals generally are hard when compared with many of the non-metals, but at the same time they possess properties of malleability and ductility which are not possessed by non-metals.

c) Metals generally have high densities.

d) Metals are good Conductors of heat and electricity, which non-metals are poor conductor.

e) Metals have low specific heats compared with non-metals.

f) Most metals reflect nearly all wavelengths of light equally well ; for which reason they are white, or nearly white, in colour. Notable exceptions are gold and copper.

g) Metals are comparatively difficult to penetrate with X-Rays.

h) Most metals are magnetic to some slight degree, but only in the metals iron, nickel and cobalt is magnetism strong enough to be of practical interest. The pronounced magnetism of this group is usualy called "ferromagnetism".

. MECHANICAL PROPERTIES OF METALS

STRENGTH

- The

strength of a material is its capacity to withstand destruction under

the action of external loads. The stronger the material the greater

the load it can withstand. It, therefore, determines the ability of a

material to withstand

stress without failure. Since strength

varies according to the type of loading, it is possible to assess

tensile, compressive, shearing or torsional strengths.

On the basis of bonding forces, it can be said that materials with pure covalent bonding would be strongest and that those with pure ionic bonding would be nearly as strong. Metallic bonding would be clearly third and molecular bonding would be weakest.

2) ELASTICITY - Elasticity is that property of material by virtue of which deformations caused by applied load disappear upon the removal of the load. In other words, the elasticity of a material is its power of coming back to its original position after deformation when the stress or load is released. The recoverable nature of elastic deformation makes it possible to store elastic energy in solids and to release it under controlled conditions. Elasticity of solids has its origin in the existence and stability of interatomic and intermolecular bondings.

3) STIFFNESS - The resistance of a material to elastic deformation or deflection is called stiffness. A material which suffers very slight deformation under load has a high degree of stiffness.

If the material follows Hook's Law, i.e. it has a linear stress-strain relation, its stiffness is measured by the Young's Modulus E, also Variously termed the "modulus of stiffness" or "modulus of elasticity", by measuring the slope of the straight line of stress-strain diagram, since

E

=

![]()

The term flexibility is sometimes used as the opposite of stiffness. However, flexibility usually has to do with flexture or bending.

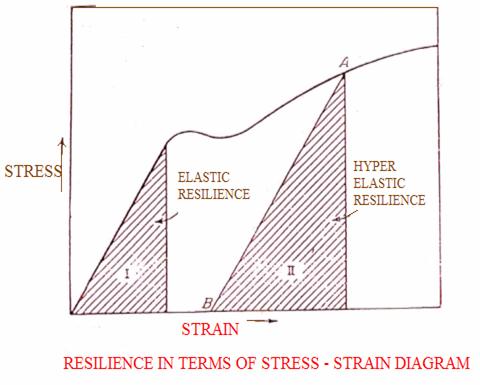

RESILIENCE - Resilience is the Capacity of a material to absorb energy elastically. When a body Is loaded without exceeding its elastic limit, it changes its dimensions, and on the removal of load, it regains in original dimensions. In fact, the body behaves perfectly like a spring. So long as it remains loaded, it has stored energy in itself, which is called strain or internal energy. On removal of the load, the energy stored is given off exactly as in a spring when the load is removed.

The maximum energy which can be stored in a body up to the elastic limit is called the proof resilience and the proof resilience per unit volume is called the modulus of resilience. Thus energy stored per unit volume at the elastic limit is the modulus of resilience. This quantity is a mechanical property of the material and gives capacity to bear shocks and vibration.

5) PLASTICITY - The plasticity of a material is its ability to undergo some degree of permanent deformation without rupture. Plastic deformation takes place only after the elastic range has been exceeded. Evidence of plastic action in structural materials are called yield, plastic flow and creep.

Plasticity is of importance in forming, shaping and extruding operations such as cold drawing, hot rolling and forging. In general, plasticity increases with increasing temperature.

6) DUCTILITY AND MALLEABILITY - Ductility is that property of a material which enables it to draw out into thin wire. Mild steel is a ductile material, the percent elongation and the reduction in area in tension are often used as empirical measures of ductility.

Malleability of a material is its ability to be-flattened into thin sheets without cracking by pressing, rolling, hammering etc. Aluminium, Copper, tin, lead etc are malleable metals.

Although ductility and malleability are frequently used interchangeably, ductility is thought of as a tensile quality whereas the malleability is considered as a compresive quality.

Some materials may be malleable but not ductile, Lead, for instance, can be readily rolled and hammered out but cannot be drawn into wire.

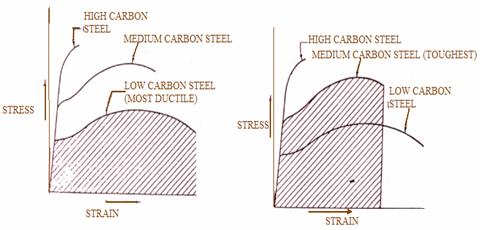

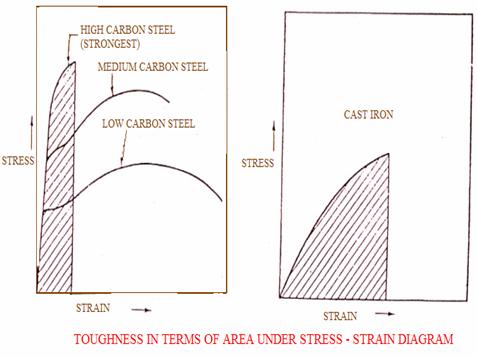

7) TOUGHNESS - The toughness of a material is its ability to withstand both plastic and elastic deformation. It is, in fact, the amount of energy a material can absorb before actual fracture or failure takes place. Toughness is highly desirable quality of machine parts which have to withstand shock and vibration. Manganese steel, wrought iron, mild steel etc. are tough materials.

Although, it is nearly impossible to measure toughness in absoulute units, it is usually represented by the area under a stress-strain curve and thus involves both strength and ductility. The total area under the curve, is the work expended in deforming one cu metre of the material until it fractures. This work or energy is sometimes called the modulus of toughness. Toughness is related to impact strength, i.e. resistance to shock loading.

HARDNESS, HARDENAB1LITY AND BRITTLENESS - Hardness,of a material is the ability to resist abrasion or indentation and also is a measure of the wearing quality of a material. It is closely associated with material structure, composition and other mechanical properties.

Hardenability indicates the degree of hardness that can be imparted to a metal particularly steel, by the process of hardening. It determines the depth and distribution of hardness induced by quenching. Hardness is associated with strength, while hardenability is connected with the transformation characteristics of a steel. Hardenability may be increased by the transformation kinetics by the addition of alloying elements, while the hardness of a steel with given transformation kinetics is controlled primarily by the carbon content.

The brittleness of a material is the property of breaking or shattering without much permanent distortion. Cast iron and. glass are good examples of brittle materials. The lack of ductility is commonly called brittleness. Usually the tensile strength of brittle materials is only a fraction of their compressive strengths.