FRESH WATER GENERATION - REVERSE OSMOSIS PRINCIPLE

Osmosis is the term used to describe the natural migration of water from one side of a semi-permeable membrane into a solution on the other side. The phenomenon occurs when moisture from the soil passes through the membrane covering of the roots of plants, with no loss of nutrient liquid from the plant. The membrane acts as a one way barrier, allowing the passage of water but not of the nutrients dissolved in the liquid within the root.

Principle :

If a salt solution which has an electro-chemical potential, is separated from pure water which has a lower chemical potential by a semi-permeable membrane, then pure water will flow through the membrane so as to reduce the potential of the salt solution.

This process will continue until all the pure water has passed through or until the hydrostatic head of the now diluted salt solution is sufficient to arrest the flow.

When the hydrostatic head just arrests the process, the pressure is called the Osmotic pressure.

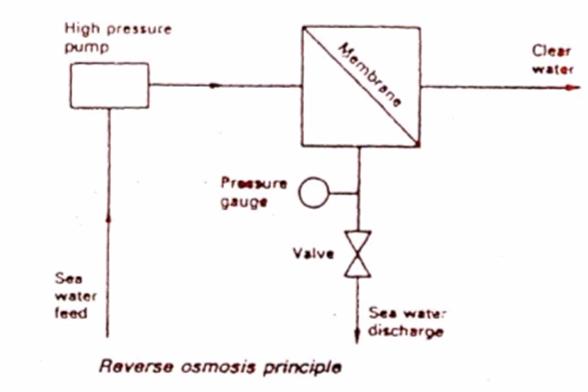

Reverse osmosis is the forcing of pure water from a salt solution through a semi permeable membrane by the application of pressure. The applied pressure must obviously be higher than the osmotic pressure.

Sea water osmotic pressure is about 28 bar. The rate of flow through the membrane depends on (a) the temperature of the water and (b) the net driving pressure.

The semi-permeable membrane and the parchment are like filters. They allow the water molecules through but not the larger molecules of dissolved substances. The phenomenon is important not only for the absorption of water through the roots of plants but in animal and plant systems generally.

Reverse Osmosis is a water filtration process which makes use of semi-permeable membrane like materials. Salt water (sea water) on one side of the membrane is pressurised by a pump and forced against the material. Pure water

passes through but the membrane is able to prevent passage of the salt. For production of large amounts of .pure water, the membrane area must be large and it must be arranged in a configuration which makes it strong enough to withstand the very high pump pressure needed.

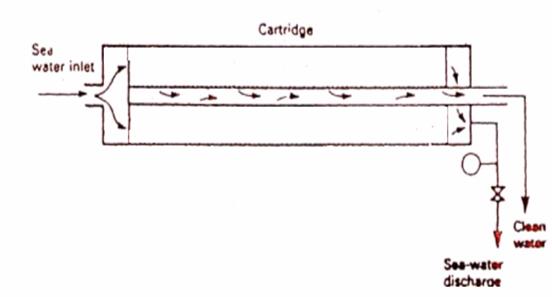

The pump delivery pressure for a reverse osmosis system requires a robust reciprocating or gear pump delivering 60 bar pressure. Man-made membranes produced are in the form of polyamide or polysulphonate sheets. The large area and strength of membrane is provided by making spirally wound cartridge. The core of the cartridge is a porous tube to which are attached the open edges of a large number of envelops each made of two sheets of the membrane material. The envelop sealed together in three sides, contain a sheet of porous substance which acts as the path to the Central porous tube for water which is squeezed through the membranes. Cartridge with end- spacers are housed in tubes of stainless steel.

Sea water feed for reverse osmosis is pretreated by passing through a chemical (5 mg/litre) sodium hexametaphosphate to assist the wash through of salt deposit on the surface of the elements and the sea water is sterilised by chlorine or silver-ion to remove bacteria which would otherwise become resident in the filter, chlorine is reduced by compressed carbon filter while solids are removed by other filters.

Where there has been pH adjustment of feed water (required with cellulose Acetate type membrane), then the product water will require pH re-adjustment (usually by soda-ash). Degassing may also, be needed in addition to chlorination. To comply safety requirements, an automatic product dump system solenoid valve controlled by conductivity is fitted. Other instruments would measure permeate flow, membrane pressure and differential pressure across the membrane. Membrane detarioration is monitored by measuring permeate flow and differential pressure, when the decline is 10%, then chemical cleaning is required. Average membrane life is 3 years.

Cartridge for reverse osmosis