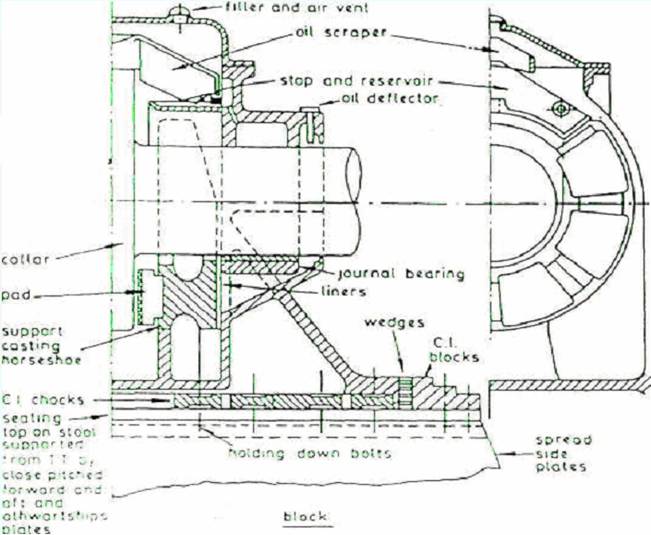

Thrust Pads :—

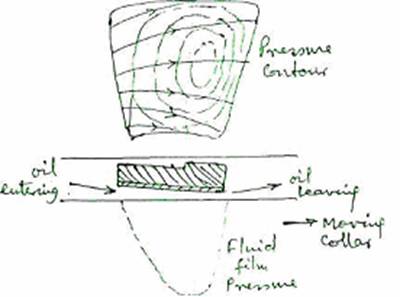

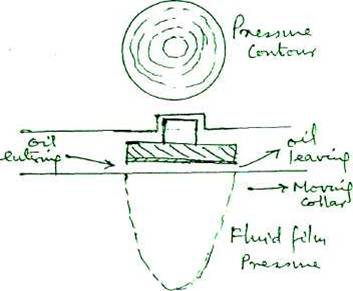

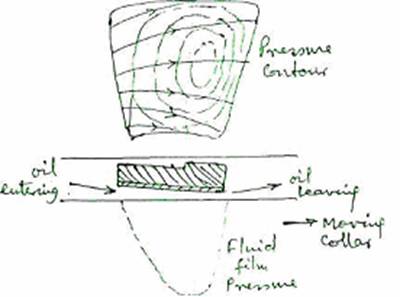

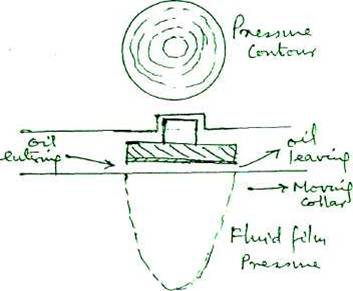

White metal lined kidney shaped thrust pads are fitted radially in the inverted horse shoe steel castings. The pads are secured circumferentially against rotation, by the stop. The oil scraper bears on the outer periphery of thrust collar and delivers oil to resevoir-stop from where it cascades on to the pads and bearings. The radial pivot line at the back of thrust pads varies from half to 2/3 rd of the pad width from the leading edge. The pivot position may be central or offset. Offset pads are interchangeable in thrust block for direct reversing engine with fixed pitch propellers. Offset pads for CPP are not interchangeable. Two sets are required. If CPP fails and engine has to run astern, two sets of pads, one normal and one opposite alternately are fitted to the astern side. However pads with central pivot are interchangeable. Some modern thrust blocks are fitted with circular pads and pressure contours across the pad found to be more effective than kidney shaped ones.

The thrust pad support castings are backed on to liners so ensuring location in fore and aft direction and fixing the clearance, which can be adjusted. The lower half casting acts as an oil reservoir pump, being provided with oil level gauge glass and a cooling coil.

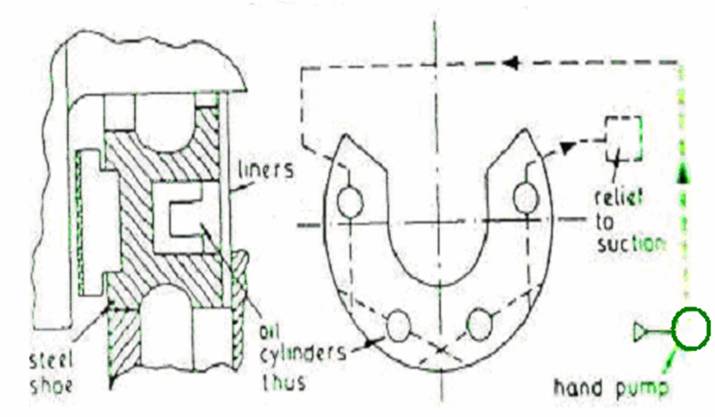

Mitchell Thrust Indicator :-

The thrust pads are held in forged mild steel shoe instead of cast steel shoe, having a number of holes in the back making up inter-connected oil cylinders. A hand pump, pressure gauge, piping and relief valve arrangement are provided and by applying oil pressure from hand pump, the internally formed pistons move forward so transferring gradually the thrust load from the lines to themselves, the thrust shoe then floats on pistons and pressure is read on the gauge when half the axial clearance have been traversed, the relief valve lifts so preventing over pumping. Astern thrust could be measured by a duplicate on the other side of the collar. The piston loading pressure is about 175 bar.