COUPLING FLANGE :

The coupling arrangement can either have a flange forged integral with the shaft or loose, depending on requirements. Flanges that are forged integral with the shaft have their thickness, determined by classification society rules, at least equal to the diameter of the flange coupling bolts measured at coupling face. The flange thickness should not be less than 0.2 times the diameter of the shaft. The forging of the flange with the shaft must be provided with a fillet radius which is machined in and must not be-less than 0.08 times the diameter of the shaft: These fillets must have a smooth finish.

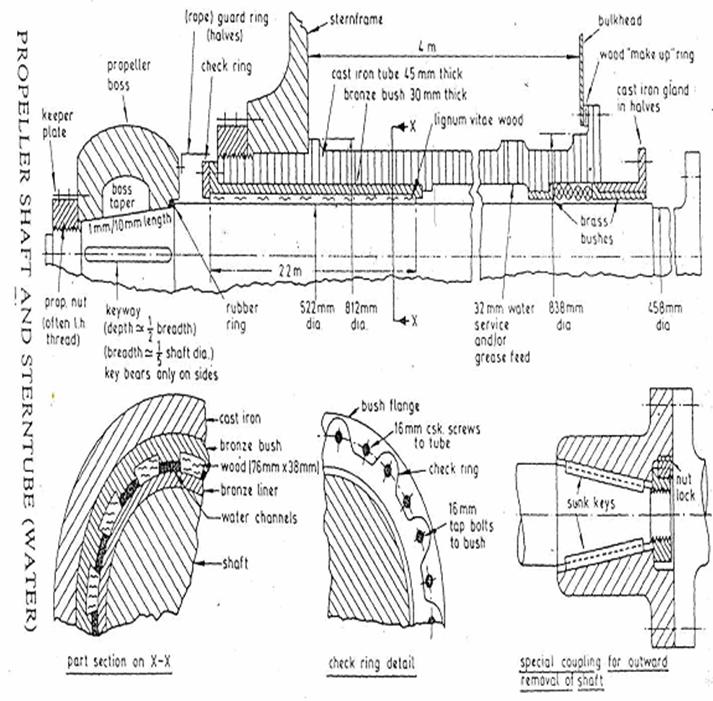

Loose complings are usually fitted to the last line of intermediate shafting connecting it to the tailshaft. This method of coupling permits the removal of the tailshaft through the stern bearing.

There are two types of loose couplings in common use are

a) Muff coupling

b) Keyed and flange coupling.

SKF (Muff) coupling

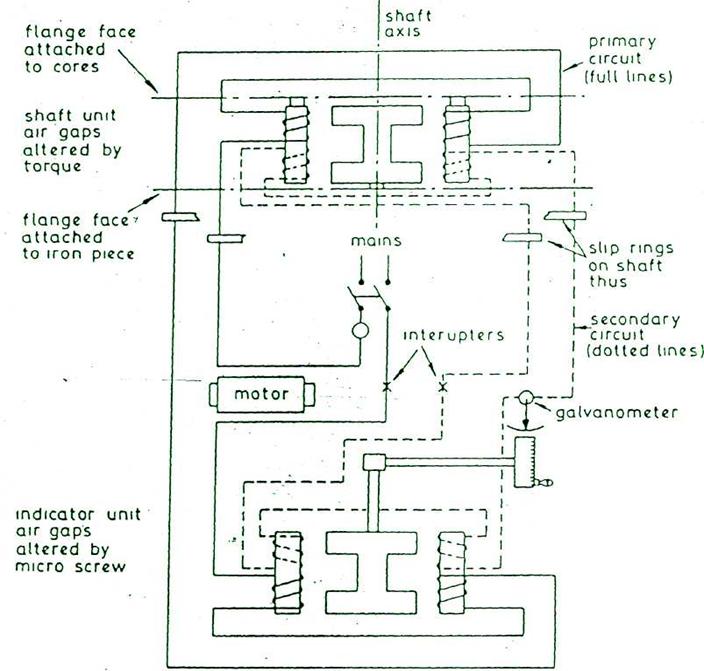

ELECTRICAL TORSION METER

THRUST SHAFT :

It is subjected to torsional stress and end thrust but virtually no bending stress would occur in such a short length over a stiffened tank. The thrust action on the collar would require a thickner diameter at the collar root but once clear of say the thrust pads, the shaft could be tapered down to the intermediate shaft diameter.