CAUSES OF DEFLECTION :

1) An excessively worn .bearing will inevitably give shaft misalignment. Only when the wear down readings of main journal bearings have been taken and satisfactory adjustments to the worn bearings have been made, should any attempt be made to rectify any misalignment indicated by deflections.

2) A simple but effective check on the validity of a set of deflection gauge readings is the 'complemental check'. That is, the top plus bottom readings should be rough equal to the port and starboard readings added together. Any large discrepancy in this should prompt the taking of another set of readings from the units concerned. Should the same readings be found then it is more than likely that there is some major misalignments in the bedplate, not just in the horizontal plane as is the norm but also in the vertical. The bedplate is probably twisted ! Thankfully, such conditions are very rare and more often than not, the bedplate is disturbed in the horizontal plane alone. If the main bearings are in satisfactory conditions, then the support of the bearing housing is the suspect.

a) Failure (cracking) of the fabricated transverse girders or perhaps the loss of support, locally, of the bedplate itself or cracked, broken, worn or missing chocks.

b) Upsetting of the tank top caused perhaps by hogging and sagging in heavy weather, grounding, collision and so on.

c) Bulged tank top due to overpressuring of double bottom tank.

d) Combined effect of slightly worn chocks, trim of vessel, cargo distribution or ballast distribution throughout the length of ressel, temperature of tank plating immediately below engine and overhanging'weights of flywheel, detuners etc.

e) Turning gear in turning the engine must overcome the static friction of the running gear. With todays more flexible shafts, there is a large possibility that the crank system may be 'wound up' a little. This twist could distort the readings adjacent to the turning gear. To check for this, stop the turning gear at each reading and back it off the teeth of the flywheel. Any change in the deflection gauge indicates that the shaft was being twisted and the readings with the turning gear backed off are the valid ones.

f) If the shaft is not seating on the main bearing housing, then deflection gauge readings will be incorrect.

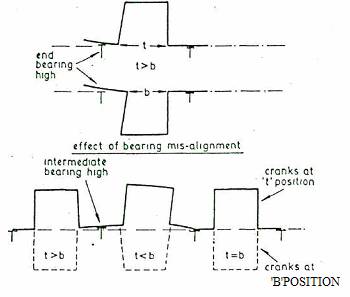

DEFLECTION READINGS AND BEARING HEIGHTS