ROTARY VANE STEERING GEAR :

A single, unit Rotary Vane Steering gear may be regarded as equivalent to a two-ram gear may be regarded as equivalent to a two-ram gear without failure redundancy. An assembly of two rotary vane gears, one above the other, can provide the security of a four ram gear.

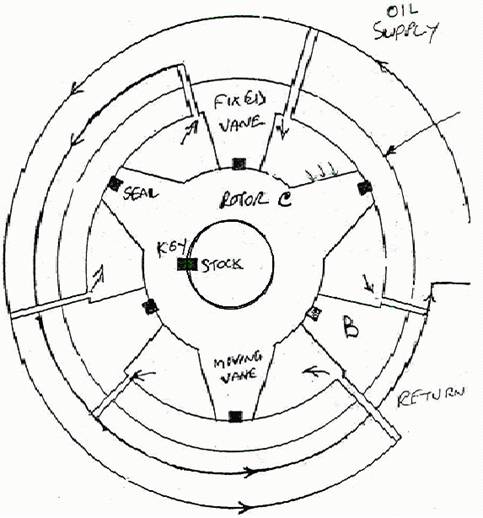

The rotary vane unit is normally fitted with three fixed and three movig vanes, and permit a total rudder angle of 70° i.e. 35° in each direction. If larger rudder angle movement is required then only two fixed and two moving vanes will be used, which ■will permit an angular movement of th'e rudder of 130°, however the force on the vanes will have to be increased for the same torque as given by 3 vanes.

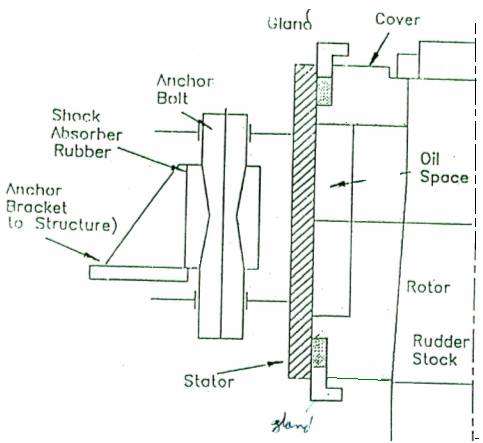

The rotor C is fitted and keyed to a tapered rudder stock, the stator is secured to the ship's structure. Fixed and rotary vanes are made of closed grain spheroidal cost iron and secured equidistantly to the Cast Steel Stator and rotor by high tensile steel dowel pins and cap screws. Keys are also fitted along the length of the rotary vanes for mechanical strength. The vane fixing is considered to be of sufficient strength to make them suitable to act as rudder stops. Steel sealing strips (each about 6 mm square section) backed by synthetic rubber are fitted in grooves along the working faces of fixed and rotary vanes thus ensuring good sealing and high volumetric efficiency of 96-98%, even at the relief valve pressure of 100 bar or o\/er.

The annular space between stator and rotor vanes are connected to two manifolds and form two sets of pressure chambers. Fluid supplied by the pump at a pressure to one set of these three chambers states the rudder in one direction and the fluid in the other set of three chambers squeezes out back to the puanp.

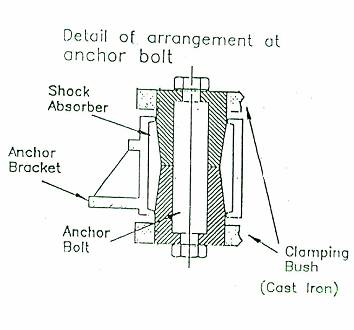

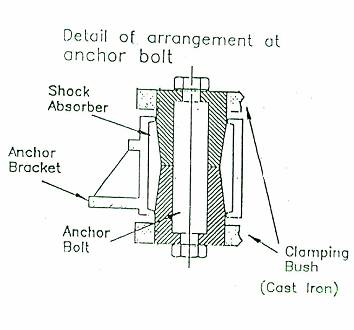

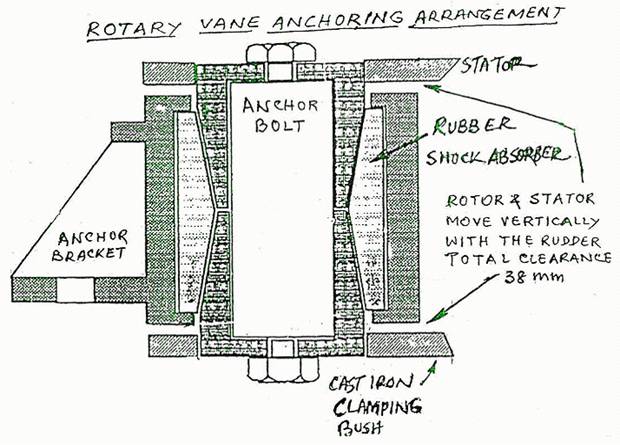

The weight of the rotary vane unit is taken up by the rudder bearing. The rotation of the stator B is prevented by means of two anchor brackets and anchor pins. The anchor brackets are securely bolted to the ship. Vertical clearance is aranged between the inside of stator flanges and the top and bottom of the anchor brackets to allow for vertical movement of the rudder stock. This clearance varies with each size of the rotary vane unit, but is approximately 38 mm in total and it is necessary that the rudder carrier should be capable of restricting the vertical movements of the rudderstock to less than this amount.

The shock absorbers (rubber) between anchor brackets and stator compensates for undesirable movement at the rudder stock, as well as providing for some small distortions of the foundations.

Advantages :

1) Can be fitted without a rudder carrier.

2)Steering gear applis a pure torque to the stock, eliminating any transverse loading on the rudder bearings.

3) Compact, hence are useful with twin rudder application.

4)

Saving in weight, reduced initial cost.

Disadvantages

:

Efficient

seal is difficult to achieve, this with small movements over much of

the

operating life can lead to problem.

1) Mechanical advantage is one.

2) Has a leakage path from high to low pressure side.

Usually limited to ships requiring low rudder torque.